Flat operated roofs are becoming increasingly popular every year, since the cost of housing and land is becoming more expensive, and this design allows you to make an additional useful space. For the arrangement of such a roof, special materials must be used and adhere to special technology. About how the installation of a flat roof we will talk in our article.

Content

Types of flat roofs

The technology of flat roof is determined by its functional load. Therefore, to begin with, it should be determined what is the operated roof, and how it differs from the usual. The rampant lies in the title - the operated roof can be operated, that is, to use as an additional useful space. Some prefer to break mini-gardens on it, others make a rest area with a brazier and tables, on flat roofs open restaurants, build sports grounds, hold concerts and make car parking. What to say is a brilliant solution for the metropolis.

Distinguish classic and inversion roofs. The difference between them consists only in the order of the heat insulating layer inside the roofing pie. So, in the first case, the insulation is under waterproofing, and in the second - above it.

The operated flat roof is a flooring, which includes all the components of the usual "cake" - vaporizolation, waterproofing, insulation and finishing coating. But in addition, such a roof is replenished with a strong overlap that can withstand serious loads. It is very difficult to make a similar design and quite expensive, but it is much easier and cheaper than to build an additional living area "from scratch".

Device operated roofing

The device of a flat roof of an operated type differs from any other kind of roof, and the order of work is determined by the type of building and the materials used.

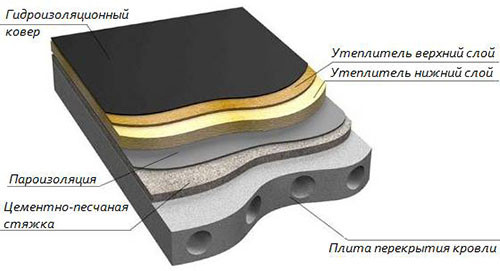

Any operated roof consists of the following layers:

- the bearing plate - usually this is a reinforced concrete monolithic structure that assumes the entire load provided by materials underlying from above, furniture and objects placed on the roof, people on it;

- row is a special leveling layer, which provides the minimum required slope for water removal from the roof surface;

- parosolation - experts recommend using modern beaten bitumen, self-adhesive films or mastic (layer thickness 1-2 mm). In this case, vaporizolation takes on the function of temporary or spare waterproofing;

- thermal insulation - the insulation must be resistant to moisture and have minimal moisture absorption, its thickness can be at least 150 mm (better than 200 mm). Another mandatory requirement is strength and durability. Well established express themselves expanded foam and foam glass;

- waterproofing - ensures the safety of thermal insulation and the integrity of the carrier plate, so for the protective layer it is necessary to choose only the highest quality materials, tested;

- finish coating - gravel or sand powder, cement screed, terraced board, lawn, ceramic tile or any other suitable material.

Thel roof

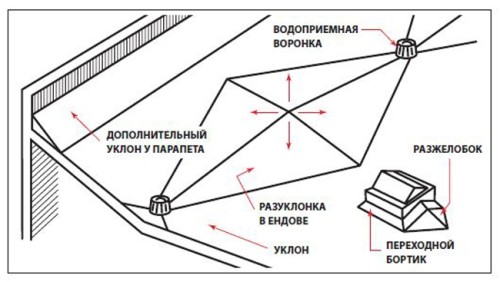

Despite the fact that the roof is called flat, it still needs to be a small slope. This required measure is needed to ensure the flow of rain and melting water. Otherwise, they will linger on the surface, spoil the finish coating and bring the "pie" into disrepair. To set water the direction and make itching in the right place, a very small deforming is enough - from 1 to 5 degrees. It is completely imperceptible or visually nor feel.

However, it is only a little bit to check the surface, it is necessary to make the drain for the water, according to which it could leave the house and go out. Funnels for a flat roof will help organize a safe removal of excess moisture.

There are several ways to create a flap:

- the use of bulk materials;

- pouring concrete with the addition of bulk materials;

- pouring concrete with polymer fillers;

- laying additional insulation.

For the first method, various bulk materials are used - crushed stone, claymzit, crumb. They are quite cheap in procurement, but the installation causes many difficulties. At first, the waterproofing layer is placed on the concrete base, which poured crushed stone or clamzite on a given slope. In order for the granules to maintain their position, they are watered with "cement milk", which performs the role of adhesive substance. When the bulk particles are grabbed, start laying the subsequent layers of "cake". However, very often "cement milk" cannot provide reliable fixation, and the granules are still rolling. As a result, the angle is changed, and the pitch does not match the required parameters.

In the case of the creation of a flat roofing, with the help of concrete, its weight can be too strong on the carrier slab, and it simply will not stand it. This option is suitable only if the arrangement of the operated roof with concrete flashes was taken into account at the design stage of the building.

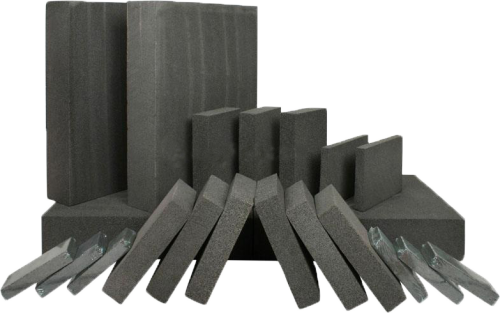

It turns out that the first three ways are or complex, or impracticable at all. Fortunately, the abundance of modern building materials allows you to find an alternative solution, and not one. To create a smooth and imperceptible liplon of the roof, use lungs and easy-to-install materials: polyurethane foam, foamed polystyrene foam, glassizol, foam concrete plates, stone cotton wool, fiberglass, foam glass, etc. There is also a special system of the RUF-bias, which involves laying of stone blocks in a special way.

Making a flap of flat roofing mineral wool or polyurethane foam plates is much easier, faster and more profitable than messing with clay and concrete. The most important advantage of such materials is low weight with impressive rigidity. They are glued on top of waterproofing with various mastic or special compositions so that the strength of the gluing is higher than the tensile strength of the insulation.

As for the use of foam concrete to arrange the defects, it will require special techniques and qualified workers. At first, a layer of foam concrete is applied to the base, which is overlapped by a foamybobetonic screed. As this entails additional spending, most prefer the above-mentioned plates, especially since the result in all cases is equally good.

Ruf-slope is a special technology for creating a flat roof flap, developed by Rockwool. Its essence is that an individual system is selected for each roof design, providing an optimal bias and fast water flow. Development and calculations are fully automated, so errors can not be. When the program calculates all the data and issued a virtual model of rally, a set of panels with the desired slope is made at the factory. Elements are delivered to the place of assembly and mounted on the principle of puzzle, after which they are covered with a layer of liquid rubber. It is worth such a service is quite expensive, but it should be borne in mind that you get both the flashed and insulation, and additional waterproofing.

The slope of the flat roof is necessary in order for water to be delayed on the surface and flow into a certain place, but to remove it from the roof, it is necessary to equip the drainage. The hosted funnels are installed on each roof sector, and in the case of the inversion type of the design of the funnels, the moisture is required not only from the surface, but also from the waterproofing layer.

Heavy insulation roofing

The heat insulating layer for the operated roof should be made of durable (not soft) materials resistant to moisture and blood pressure of the roof. In mandatory, the insulation needs vapor barrier to ensure additional protection against moisture. When choosing film materials, such as polyethylene or polypropylene, it should be borne in mind that there will be seams between the cuts - potential risk zones. Therefore, many prefer a seamless vapor barrier from bitumen or polybitum.

For thermal insulation, a flat roof is most often used stone or mineral wool in the plates, extruded polystyrene foam or foam glass. The last two materials are distinguished by almost complete hydrophobicity and in all circumstances remain dry, therefore they are considered the best option for laying a flat roof. The only nuance is high cost, especially foam glass. In the case of expanded polystyrene, it is also necessary to provide additional fire safety and protect the insulation from the effects of ultraviolet.

Mineral wool slabs are not lit and cost rather cheap. However, this material needs serious moisture protection - the slightest wet, and the slabs cease to fulfill their destination. In addition, mineral and stone wool do not have the necessary strength, so they need additional strengthening. Often for this use a cement screed - it evenly distributes the load, is an additional protection for the stove and gives a smooth and durable base for laying the waterproofing carpet.

There are prefabricated and wet ties. The national team makes slate or asbestos sheets, and it is quite expensive. The wet screed looks in the form of a classic cement-sand solution, which is poured insulation. This option is much cheaper, but provides an additional load on the stove and the foundation. In addition, when pouring moisture from the solution is necessarily absorbed into the insulation, so you need to raise the protective layer of kraft paper or pergamine. He dries a wet screed for a very long time (up to 3-4 weeks), and if you try to apply waterproofing, without waiting for complete drying, it will necessarily be bubbles on the surface. From all this, you can make a logical conclusion - it is better to spend money on a durable insulation than to buy cheap mineral wool and make a tie.

For insulation of a house with a flat roof, experts recommend using high-strength basalt mineral wool plates. Their special production technology, which involves the double orientation of the fibers (weave), guarantees high rigidity and durability.

Whatever the insulation for the operated roof you chose, it must meet the following requirements:

- not absorb moisture;

- do not swell;

- do not rot;

- do not give a shrink

- be durable

- be durable.

Waterproofing

The waterproofing of the operated roof should be paid to special attention, since the preservation of not only roofing pie depends on its quality and stacking, but also the whole building. Regardless, building you a soft flat roof or exploited inversion, waterproofing work is equally.

If earlier the roofs were covered with liquid bitumen, today they are preferred by rolled-powered materials, between which there are no seams (rubberoid, polymer-bitumen materials, PVC membranes, etc.). Bituminous polymeric materials are distinguished by high elasticity and simplicity of installation. Especially popular among them is given by cast asphalt, self-adhesive film and various emulsions.

Features of styling waterproofing:

- The preparation of the base is to purify the roof from the garbage using a compressor or brush. Before working with the compressor, it is recommended to install the screen on the perimeter of the roof (barriers) that will not allow the garbage to fly down. To remove contaminants in the joints of the antennas, ventilation mines and other hard-to-reach places, use a drill with a brush nozzle.

- If you plan to lay waterproofing over a concrete screed, remove the frozen cement milk using the grinding machine. As a result, you will remove the top layer of the screed and open the pores of the concrete. In the process of burning the waterproofing material, they will be purchased by them, thereby ensuring a more reliable connection.

- Check the surface for defects. When cracking or cracks are detected, fill them with cement-sandy mortar. If there are bubbles on the old waterproofing coating, it means that moisture accumulated under it, and it should be completely replaced.

- Concrete base before laying waterproofing should be processed by primer.

- Stacking the installed materials is easy to do independently if you know how to use the gas burner. Warm the back of the material, attach it to the roof surface and begin to gradually turn the roll, continuing to boost the offside of waterproofing so that it can be glued to the base.

- Subsequent bands are laid with the allen on the previous ones about 10 cm, pressing them with a wooden manual. Manufacturers of rolled waterproofing made a special "tip" in the form of a drawing on the wrong side - when it starts to deform and "sail" from the heat of the burner, you can roll the material to the base.

- To ensure high-quality waterproofing of the operated roof, it is recommended to lay the material into two layers with a small displacement so that the strips of the second layer overlap the joints of the first.

Waterproofing liquid rubber today is considered the best and most reliable way to protect "Pie" from moisture penetration for a period of 20 years and longer. In addition to the fact that liquid rubber after frozen gives a solid seamless coating, it simultaneously performs the role of vapor barrier, so it is often used in cases where there is no possibility to buy additional building materials. The only nuance is to create such protection need a special technique and the skills of handling it. Application of liquid rubber should be carried out in windless dry weather.

Such waterproofing is used not only to protect roofing pies, but even during the construction of the pools - frozen tires reliably holds all moisture on the surface.

Finish coat

When all nodes of a flat roof are installed, you can begin to the final stage - the installation of the finish coating. When it is elected, it should be repeated not only from the performance characteristics of the material, but also take into account your own preferences. The correctly selected coating will set the mood to the whole interior of your future open-air platform. We propose to consider the most popular materials used to finish the operated roof.

Important: regardless of the coating, it is necessary to install parapet for a flat roof throughout the perimeter. It will perform a protective and decorative function. The height of the parapet depends on what purpose you build a roof pad. If this is a sports room with a basketball ring or tennis court, instead of a parapet, you should install a high grid.

Tile on the roof

A tiled, ceramic, marble, porcelain, granite, and other durable plates can be used as an outdoor coating of a flat roof. The main thing is that the surface is not slippery. Tile is put on special plastic coasters, granite rubbing or solution.

Plastic support-bagels are quite inexpensive, but the range of their adjustment is limited to 15 mm, so the bending of the finish coating will correspond to the roof slope. However, experts came up with how to eliminate this disadvantage - before installing the supports they level the base with rubble.

Another thing is the support columns. They have a wide range of adjustments and provide a smooth surface with any roof slope.

Pebble and rubble on the roof

In most cases, rubble performs the function of the leveling layer on which more aesthetic material is placed. But it can become a finish coating if you want to diversify the landscape design or make a neat paths.

When arranging plantings on a flat roof (green roof), crushed stone is used as a drainage to ensure uniform plant saturation with water and prevent soil fever.

Useful advice: Experts recommend using granite crushed stone instead of lime, because it is much stronger and is not destroyed by moisture.

Smooth stones, tired river or sea, you can post a very beautiful surface at which it will be useful to walk barefoot. From the pebbles of various colors and shades, original compositions are obtained, smooth neat tracks and decorative elements.

Polymer coatings

Polymeric materials for the operated roof provide a smooth seamless surface that does not transmit water and capable of carrying temperature differences. Depending on the composition, the characteristics and method of coating are distinguished. Thin coatings are applied with brush or roller, thick - poured and align.

Thin polymer coatings are mainly colorless (transparent) and serve to create a protective film for mosaic, natural stone or tiles. They do not allow the finish coating to crack from a strong frost, fade from direct sunlight and split from random strikes. Such protection can serve until 20 years and longer.

Tolstoneal polymer coatings are made of plexiglas. After frozen, they form a dense layer with a thickness of about 20 mm. The main advantage is that after pouring a self-leveling mixture to the surface, the floor can be used after 2-3 hours. The average service life of such a coating is 50 years.

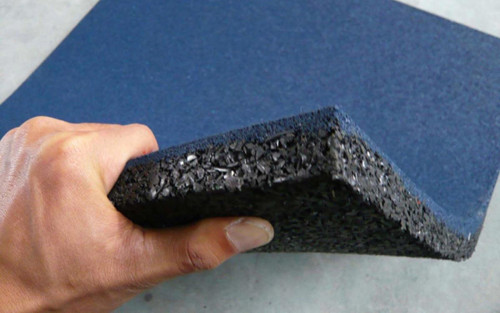

Rubber tile

Rubber tile has proven itself as a reliable universal coating that can be used both indoors and outside. It does not fade under the sun and is not afraid of moisture, does not undergo under the severity of furniture and has a long service life.

Rubber tile is made of recycled car tires. They are grinding into the crumb and pressed under greater pressure, resulting in dense, elastic and very durable "mats". Depending on the model and the purpose of the tile can be connected to each other with special locks or fit into glue as a conventional tile.

This material is ideal for finishing the operated roof, since it does not slip at all, even if water was wetted. As the rubber is quite elastic, albeit dense, it removes the load from the legs during walking.

Terraced board

The most aesthetic type of floor covering for a flat roof. The flooring makes dense valuable wood - larch, cherries, teak, Merbau, etc. Such a finish is quite expensive, but there is a more budget option - a terrace board of wood-polymer composite. Externally, it is practically no different from the "noble" wooden, so many prefer such a coating.

It is practically no need to care for a terrace board - as a rule, it rains all pollution, and if it remains, you can simply brush it with a brush. Installation also does not cause difficulties - for the terraced board, the same supports are used as for tiles, and Decking is installed on special attachments (come in the kit).

Before purchasing materials, it is necessary to produce an accurate calculation of a flat roof, taking into account the bearing abilities of the walls and the foundation of the building (if it is already built). Ideally, the operated roof is better planning at the design stage of the house itself.

Excellent article. Let us hope that we will implement such technology.

thanks

Porcelain stoneware 20 mm More than 130 models with a different surface and texture for the roof