When designing and laying a power supply system, there are many difficulties. Considering the danger that the incorrectly executed layout of the line carries, to fulfill all the work in this direction, we assume very carefully and clearly follow the standards and recommendations. When building your own home, the process is considered only after proper isolation of all elements of the system.

Content

Why isolate electrical wires pipes?

With any direction of construction, it is especially important to create reliable protection of the wiring in order to prevent emergency situations or interruptions in the work of the system.

The use of plastic pipes allows you to prevent the following destruction factors:

- wiring freezing;

- excessive watering;

- mechanical impact of the natural environment.

What are the advantages of using PVC pipes?

Until recently, steel products were most used, but they did not always ensure the proper level of protection. Therefore, with the advent of plastic on the market, it was preferred, because of multiple advantages.

We highlight the main advantages of using PVC pipes for wiring:

- excellent strength;

- resistance to any type of aggressive impact;

- long period of operation without the need to regularly verify material integrity;

- a light weight;

- relevant hardness requirements;

- plastic;

- minor linear extension, even with a sharp change in temperature regime;

- lack of interaction with moisture, due to which the corrosion manifestation is completely excluded;

- the ability to replace the damaged wiring inside the building without the destruction of walls or other parts of the structure.

Important! It is impossible to lose sight of the fact that buy PVC pipes for wiring can be quite quickly. The current market provides many options for products of this type. The main task when buying is to decide in advance with the desired type of details. Another indisputable dignity is that PVC pipe prices for wiring is very affordable.

What plastic pipes are used for isolation?

To more clearly imagine which plastic pipes are used to insulate wires, consider the following classification criteria:

- the size;

- the structure of the used canvas;

- ease.

Important! Pay attention not only to suitable specifications, but also the availability of certificates confirming the compliance of products to the specified parameters and GOST standards. PVC pipe indicators for wiring must comply with the following indicators:

What is the size of the pipes?

To select the right pipe diameter, consider the design features of the structure at the site of the gasket. To date, such products are represented in the range from 1.6 to 5 cm.

Use the following guidelines when choosing a suitable PVC pipe:

- At arrangement of open systems Indoor use of smaller diameter products, so as not to disrupt the attractive décor of the room.

- For installation underground, an excellent option is PVC pipes, the dimensions of which correspond 2-4 cm. This approach will ensure the convenience of installation, but it will not cause damage at constant load pressure of the soil.

- When designing the systems hidden in the structures of the system, focus solely on the thickness of the cable and the size of the nodes. We especially carefully take effect with a parallel connection on specific sections of several cables.

- For signaling equipment or lighting devices, use PVC pipes whose diameter is 1.6 cm.

- For sockets and switches, pick up 2-centimeter products.

- To combine a line with distribution boxes and panels, PVC pipes are more suitable for 2.5 cm.

- If you need to lay the line between the floors of your own home compounds, give preference to the details of 4-5 cm in the circle.

Please note when designing that the standard length of one PVC pipe is most frequent in use due to maximum convenience and transportation, and directly mounted, - 3 meters, but are present on the market with parameters from 2 to 6m.

Important! In advance, correctly calculate the desired length of the pipeline. Note that the cutting for specific parameters is simply made by any available cutting tool, as the plastic is easily processing.

What are the features of the PVC pipe for wiring?

When choosing, pay attention to the following types:

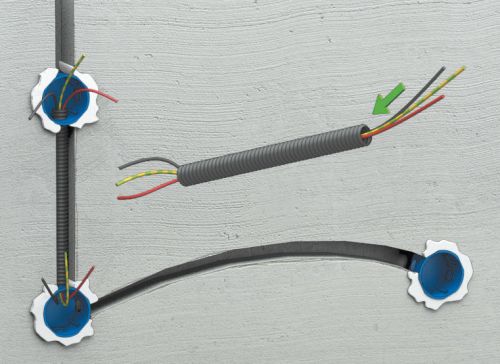

- Smooth. It is very convenient for registration of external lines of the system and for laying in the thickness of various parts of the design indoors or underground. It is the PVC pipe smooth for wiring will be an excellent solution for arranging a long trunk system.

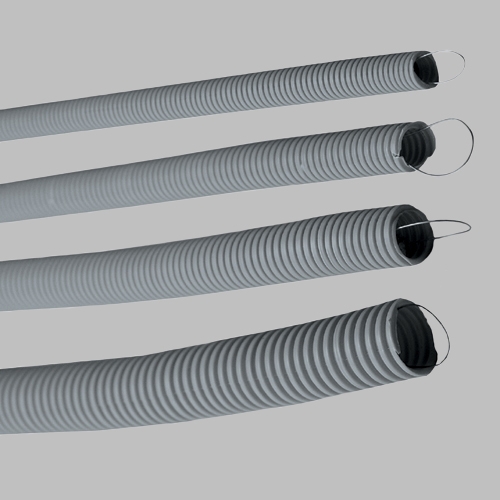

- Corrugated. Give preference to this type of product, where the alleged operation are complex, such as the sharp angles of rotation or hard to reach places. Special ductility while retaining the strength characteristics ensure adequate level of protection within the home.

Important! Depending on the component composition used in the process of forming the pipes, and the application varies. Please note that some products are suitable only for a combination of non-combustible surfaces, and other permissible use of readily flammable materials.

How to choose a suitable weight of the pipe?

To prevent undue stress on the parts of the structure and issue secure fit pipes, pay attention to the weight of the pipes specified by the manufacturer. According to this indicator recommended by shared use of methods:

- Light pipe, corrugated PVC for wiring, use everything for the hidden line. Laying is performed in this case by a non-combustible surfaces. Among the features of this result, we note the following features:

- Heavy products give preference to, if necessary, flush design on surfaces as non-flammable, and readily flammable materials. Excellent solution become plastic pipe for electric wiring, power type - for installation in thicker concrete or screed.

Important! Note that the strength of such products is much higher than that of lightweight tubes, which fully meets the requirements of laying the electrical network in harsh environments.

How to prepare for the installation of PVC pipe?

To avoid any damage during shipment or storage after purchase, the following guidelines in this regard:

- Protect pipes from damage during execution of loading and unloading.

- Do not throw or move portage.

- Transporting the tube in a horizontal position.

- Carefully carry out of the car in storage.

- Lay on a level horizontal surface during storage.

- Choose a location far from constant exposure to sunlight.

- Make a purchase for no more than 3 months before the planned implementation of all installation work.

Recommendations for the installation of PVC pipes on wiring

The entire process of insulation of electrical cables pipes PVC is simple. In order for all the work of this stage of construction, take a long time, carefully read the sequence of actions and strictly follow them.

Progress:

- Perform all installation work at a temperature not lower than -5C with the arrangement of the external part of the electrical communications system.

- Check the voltage on the network.

- Make sure it does not exceed 1500V.

- Prepare all the details of the configuration, depending on the layout of the line:

- if necessary, protective action is only on factors of mechanical influence, it suffices to form a leakage of the PVC leakage;

- if operating conditions differ in a large variety of devastating phenomena, take care of the presence of additional connecting parts. An excellent option for solving this task is compression fittings.

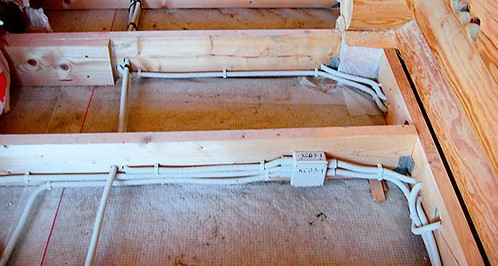

- Make the layout of the installation of pipes with electrical wiring inside.

Important! Separately, take into account the places of corners or crossing with other engineering systems. With parallel arrangement of heat supply systems, a penny makes at least 50 cm to eliminate the overheating of the electrical cables and the manifestation of failures in the supply of energy.

- Calculate the number of required mounting elements (the estimated gap is 10-15 cm).

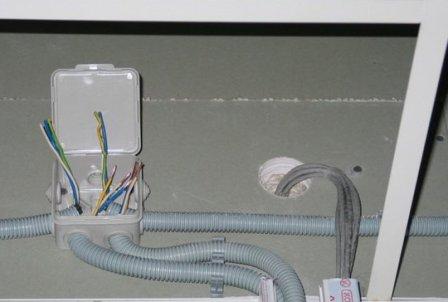

- Place the installation of shield boxes.

Important! In no case do not accommodate the wire connections inside the pipe.

- Perform cutting products according to the features of the room.

Important! When cutting corrugated products, hold the steel wire, which holds the shape of the corrugation and prevents it with stretching. Secure it with a tape to the edges of the pipe.

- Carefully scatter wires.

- Check the purity of the pipes inside.

- Start the cable through all the elements of the protective PVC pipeline.

- Sequentially set all the prepared parts of the system with a small slope to prevent accumulation on the condensate surface.

- Secure the pipes at equal intervals with aluminum or plastic clips.

- View videos with a visual example of gasket and connect all parts of the PVC protective pipe to eliminate the occurrence of any difficulties in the process of performing work.

- Install the shield and junction boxes.

- Connect all system cables to nodes.

- Review the video in which the process of designing the connection nodes is sequentially shown.

- Check insulation resistance between wires.

Conclusion

The entire isolation procedure is just as simple as it is necessary. With competent planning of the wiring of the power line and its protection, as well as compliance with all the rules of installation, the risk of emergency situations will be minimal. The whole process of operation in this case will be long and very convenient, which will certainly contribute to comfortable accommodation.