The construction of any building begins with the facilities of the foundation. The foundation of houses is currently increasingly building on monolith technology. That is, the foundation is poured right on the spot. One of the main parts of the monolithic concrete base is the reinforcing belt. Without it, concrete under the influence of mechanical and temperature loads can simply crack and collapse, which will lead to the destruction of the entire structure. The reinforcing belt is made from steel reinforcement, which should be located in concrete in a certain order. So, the distance between the rods of the reinforcement should be no more than 200 mm, and the distance from the edges of concrete is at least 50 mm. In order to in the process of filling the concrete, the rods did not change their position, the reinforcement is linked in a certain order.

Content

The process of linking the rods is quite time-consuming, considering how many connections will have to make even a small foundation for filling. And if we are talking about a full-fledged basis for a large two-storey house, it may take a single day on the installation of the reinforcing belt. Currently, several ways to link fittings have been developed, which will significantly speed up the process, making it much easier. About how to quickly knit fittings with hands - further in the article.

Knit fittings for overlapping with their own hands

To link the reinforcement use steel wire. In order for it to be easier, the carbon content should be minimal, so it should be preferred to low-carbon steel stamps. The strapping wire must go through the thermal conditions procedure to dial additional strength. Some masters use the "raw" material that has not passed the heat treatment. Although it is cheaper, but its quality is much lower. In such an important case, as the installation of the reinforcing belt of the foundation, it is not worth saving.

You can find the annealed wire in a characteristic black color. However, there is a silver material. This is galvanized wire. It has the best characteristics, less corrosion less, but it is much more expensive.

To build the foundation of the private house or garage, it is enough to use a wire with a thickness of 1.2 to 1.6 mm. Thinner material will often rush, and thicker - it is difficult to tip out.

Wire for sale both in MOTKI and already cut on a measuring length. The second option is preferable, as it takes less time on cutting pieces. The average weight of the maid can vary from 0.5 to 10 kg.

To connect the reinforcement at one point, it will take from 25 to 50 cm wire depending on the diameter of the rod. So, for a rod Ø10 mm, about 25 cm will be required, for Ø10 mm - 40 cm. At the point where three rods will have to bind (mainly in the corners) it will be necessary 50-60 cm.

Fixtures for linking reinforcement wire

With large volumes of work, it is simply impossible for manually reinforcement. First, it is quite difficult physically, and secondly, significantly reduces the speed of work. In addition, with manual mate, the wire consumption significantly increases due to residual tailings. To speed up this process, special devices are used. They are both industrial and homemade.

- Hook for mating fittings. The variety of hooks for mating fittings often puts in a dead end of beginner builders. There are simple straight hooks and with curved curved handles. Decide which configuration of the hook is more suitable, it is possible only by an experimental way, by passing several options. Recently, mechanical hooks are very popular. They differ in the fact that inside the knob of the device installed a special helix. When the master pulls the handle on itself, the hook rotates, twisting the wire.

- Pliers.This tool is more technological than the hook, thanks to which you can work with a wire larger diameter. It is raised for the place of the reinforcement and clamp in the ticks. Then the tick handle is delayed back, so that they rotate and clamp the wire. It is worth such a device quite expensive to buy it for solitary operation. So about his expediency it is worth thinking.

The most popular is another model. It provides wire twig manually. However, due to the fact that the ticks can be taken as close as possible, it is enough to turn them alone or twice and crop the remainder of the wire.

Pliers for the linking of reinforcement have special sponges that tightly hold the wire. Due to this, the material does not need to cut on dimensional pieces. It is enough to keep in one hand a small bay of wire, make a small node, turn a couple of times and cut off the end. Due to the minimum possible lengths of the ends, the material consumption is noticeably reduced, which is important when working in large volumes. Yes, and the strapping speed when using such a tool grows at times. In favor of hand ticks, the fact that in large industrial construction shots are just such.

- Pistol for mating fittings. This electric tool automatically generates a loop between two connecting reinforcing reinforcement and delays them. Most of the models of such a tool on batteries are provided complete with a charger. This tool significantly increases the speed of work, however, the wire consumption that is refilled into special reels, a little more.

A significant disadvantage of such a pistol is its cost. We spend big money in order to make the linking of one foundation, it makes no sense. It is the high cost that is the cause of the low popularity of this tool even from professional builders. Also on the way of using the power tool becomes a wire for a knitting pistol, the price of which is higher than usual.

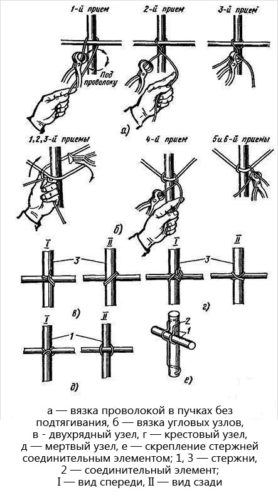

How to lifting fittings with crochet

Since the use of hooks for strapping reinforcement is most often in house construction, it is advisable to consider it. The first thing is cut on the measuring lengths. Then the segment bend in half, and the place of bending is raised by about a third, getting a kind of loop. It is raised for the place of reinforcing reinforcement diagonally and come up with crochet. The loop's free ends also have a hook, and then the latter begin to rotate, tightening the loop. As soon as the wire comes to the reinforcement, the twist stops not to break it, and the hook is removed. In the work of work it is very important to determine the power of wire tightening. If you drag it, it can break, if not reaching - the reinforcement will see and can move.

Masters of the construction industry advise: without cheating a little cheerful, pull the loop on itself. Thus, the wire will slow down slightly and after the final twist the connection will be stronger.

After the loop is tightened, free ends should be beatened for the connection so that they do not interfere in subsequent work.

If you do not want to turn the crochet manually, you can automate the process slightly. For this purpose, an ordinary screwdriver is useful. The hook for mating reinforcement is no different from the usual. After the establishment of the free end of the hook, the loop is tightened with a screwdriver. The devices of the device must be exhibited at a minimum. If you can do, one link can be done in a couple of seconds. It is impossible to use a drill in this work. Their heavy cartridge in the absence of a brake has a strong inertia, which can cause a wire break.

Recently, the reinforcement began to lift with plastic clamps. They cost any more expensive than wire, and the work is obvious. Plastic clamp has a special retainer, which allows it to tighten it only in one direction. All you need to do is to start the free end of the clamp diagonally, to turn to the retainer and tighten. However, many builders relate to such a material pretty skeptical. Although plastic is neutral with respect to the environment and within concrete with it, it cannot happen by definition, it has a stretching property. This may lead to a weakening of the design, which may in turn cause the screed destruction.

How to make a hook for mating fittings

If there is no time to buy a hook, you can simply make it yourself. At the same time, you can pick up all the tool parameters for yourself.

For the manufacture of the hook perfectly suitable wire with a diameter of 4 mm. You can use the flux electrode cleaned.

Procedure for work:

- At one end of the wire you need to make a small ring. It will act as a stop for the handle. Next, the wire needs to be around in the midst of a rocker.

- For the bottom stop of the handle on the wire, the washer is boiled. Then the handle dresses at the end of the wire. Handle manufacturer options may be several. You can make it of two steel tubes of different diameters. Lower - wear wire, and large - on top. You can also show a handle from a piece of wood. If there is a piece of any polymer, you can use it for this purpose.

- After the handle is dressed on the hook wire, it is fixed from above with another wash.

- Now you can proceed to the formation of the hook itself. The end of the wire is sharpened with the help of a grinder or abrasive circle, but not too. Then with the help of the wires of the wire bends, forming a hook. The parameters of the tool will need to be selected so that it is convenient to work with it. The main thing is that the hook is not too sharpened and did not cut the wire.