At all times, people, building houses, tried to take into account not only the beauty of the appearance of the structure, but also the practicality of the future building. The broken roof is a design that meets the requirements of beauty and convenience. Speaking at the same time the roof of the construction, it makes it possible to create additional residential meters in the form of an attic floor.

Content

What is a broken roof

This construction obtained its name due to appearance and unusual form consisting of a large number of broken lines. The broken roof is a design made in this way that makes it possible to create an additional living area on the top floor at the top floor. In addition to the practical function, such a roof plays a decorative role, bringing a highlight to the stylistic design of the building.

It is also worth noting that the traditional double roof has some limit in height, which is associated with the wind load of the structure. But the broken roof can be done much higher - this feature will allow the home owner to get a attic floor with a rather high ceiling.

Features of the design of the broken roof

- The specificity of a similar roof is that the broken roof allows the use of additional space with maximum benefit. The number of so-called "dead zones" characteristic of ordinary roofs is almost reduced. And even in those places that will remain unsuitable for living, you can make lockers or hanging the shelves.

- The most popular variant of the lone of the roof is the four-piece design. Along with the complexity of the arrangement of rafting systems, such a roof allows you to use the resulting residential space with maximum efficiency.

- The undoubted plus of the design is considered to be its relatively low cost. The construction of the broken roof with the creation of the attic will cost the owner of the house significantly cheaper than the construction of a full-fledged top floor. With proper insulation of the roof and good repair, the attic can be made suitable for living room.

- The structural roof structure, as mentioned earlier, makes it possible to make a fairly high ceiling on the top floor. This is due to the fracture of the skate, in accordance with the angle of which the free space increases.

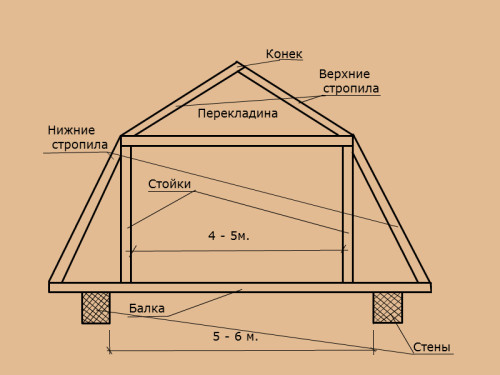

- When creating a broken roof, with their own hands, its optimal width will be considered an indicator of 6 m. For large-scale buildings will have to be resorted to other, more complex, construction methods.

- In buildings whose width does not exceed 6 m, the gain beams and the roof beams are based on such points: Maurylalat, made of a profiled bar with a cross section of 90x140 mm, as well as on a matzitz - a cross beam playing the middle reference point. In the case when the width of the span of a house is more than 6 m, a carrier partition made from a studded planed beam with a cross section of 90x140 mm.

- As a rule, window openings are present in the broken roof, often located on the frontal part of the structure. Very well in a similar architectural solutions, please balconies, as well as the remote window.

Types and forms of broken roofs

Broken roof may have a different number of rays depending on the design of the indicator is divided into such types:

- A single roof is a constructions in the form of an inclined plane, opposite to which are fixed on the walls of different heights. The project of such a broken roof is one of the easiest in the implementation, besides, a single-sided design has a completely simple rafter system. In this regard, this roof is considered one of the most popular options in the construction of private houses.

- The double roof consists of 2 slopes oppositely sent to each other. Often, such structures are present in the buildings of the rectangular shape. Two-tight roofs are no less popular than single, which is due to both their creation and high reliability of the entire design.

- In a three-axis broken roof, one of the ends is the vertical wall, the second end is performed with the same profile breaks, like the side skates. Unlike other options, such a roof has a relatively small mass, because in its design there are no single capital wall. Very often this option is used in cases when they want to attach attic to the residential house.

- The most difficult in execution, but the most practical and easy-to-use option is considered a four-tie roof, which is based on 4 skate from broken profiles.

The structures of broken roofs can be the most different, often such roofs have a parabolic shape and are intended for rectangular buildings. Short structures have a triangular shape, while long-skates have a type of trapezium.

The popular shape of the lone of the roof is the half-haired roof, which is also called Dutch. At its ends, there are sinks with a minor departure, thanks to this form, the semi-haired roof reliably protects the ends of the house from the rain, and also perfectly opposes wind loads. Semi-hail roofs are two- and four-tight.

For non-standard houses, the walls of which form a polygon or a circle, the broken roofs of the tent type are used, which, in turn, are pyramidal, dome or conical. Drawing sloping roof of any shape can be formed independently, but it is better to entrust this work professional designers and architects.

Loaven roof with your own hands

Having the sloping roof of a quality project, you can try to build your own design. We consider in detail the subtleties of the main process.

Selection of material for the roof

Often, when erecting the roof, builders are trying to make the design as easy as possible, having saved the wall of the building from excess load. That is why wood is used to create a rafter system - the lightest material that corresponds to the necessary strength characteristics. Metal and reinforced concrete during the construction of roofs for small private houses is practically no applied.

The rafters are usually made from a wooden bar. The material should have sufficient strength and have optimal humidity - reliability and durability depends on this indicator. Most of all, wood conifers are suitable for creating a rafter system, as it differs relative low cost and optimal softness. The roof shawl is performed from the edged board. Installation of all elements and bonding them between themselves are performed using brackets, brackets and screws.

The roofing material also should be selected with special care, because the durability of the roof directly depends on its weight. During the construction of private houses, galvanized iron, metal tile, various types of soft roofing materials are most often used, and reed. The choice of option also depends on the stylistic design of the building.

Determination of the size of a broken roof

It should be treated with all seriousness, since the reliability of the final result will depend on the end and carefully calculated calculation. When designing the roof, errors and errors should be avoided, since the improper distribution of the weight of the structure can lead to its destruction.

The calculation and measurement of all necessary parameters is made using instruments such as a roulette and calculator. In the process of work, you also need to have a project of a future roofing.

By producing all measurements, they should be denoted on the sketch. Find out the area of \u200b\u200bthe future design as follows:

- the design shown in the diagram is divided into simple geometric shapes;

- then the area of \u200b\u200beach of these figures is measured;

- the last step received indicators are summed up - the final value and will be the total area of \u200b\u200bthe lone of the roof.

Upon learning of the construction area, it is possible to determine with the number of roofing material that will be needed to work.

Processing of wooden elements

Before making a broken roof with your own hands, you need to take care of the protection of rafters and other wooden elements from the harmful effects of moisture, mold, fungi and other pests. All wooden elements should be treated as thoroughly with antiseptic compositions, applying them to the surface of the material at least two layers. For such a work, a wide soft brush is used, as well as gloves and a respirator that protect the skin and respiratory tract from the harmful components of the antiseptic. It is also desirable that the impregnation has both fire properties - so you protect the roof from fire.

Installation of a broken roof

After all the wooden structures are processed by the necessary means, you can start by installing Maurolalat and overlap beams. The optimal size of the beams is 10x20 cm in cross section. The design process of construction consists of such steps:

- The extreme beams of thick bar are installed vertically on two rack lines.

- Between them stretches the thread, after which the intermediate beams are mounted. The distance between such beams should not exceed 3 m, and the elements themselves are fixed with the help of temporary struts. The height of each rack should exceed the planned ceiling height by about 10 cm.

- Top of the installed racks are stacked from the edged board, after which the final fixation of the remaining beams is performed. This design will subsequently serve as a frame of the narent floor walls.

- The next step on runs are recorded tightening, which are supported from the bottom in order to ensure the safety of builders. When all tightening will be laid, they can be used for additional stiffness and reliability on top of the board.

- After that, the time of installation of lateral rafters and plugs for the insulation are coming. When the work is done, you can start the mounting of the upper rods.

- The roof rafters are installed by the template. This template serves as a fragment of the board, vertically fixed on the extreme rigel. It is worth noting that the upper angle of the template must completely coincide with the center of the future design. Focusing on the template, you need to make 2 rafters and consolidate them in the structural roof design.

- After that, you can install the remaining rafters, make the frame of the front, to cut it with its desired material, equip the eaves. Then you can proceed to the creation of crates, sings and sinks.

- When the slab roof frame will be ready, all its elements can be covered again with a water-repellent means. On top of the finished design, roofing works can be carried out.

Warming, waterproofing, roofing work

Waterproofing and insulation are a responsible process, because from properly carried out work will subsequently depend on how warm and cozy an attic room will be. The first stage of the roof is cured with waterproofing material, attaching it directly to the crate. The next layer should be any selected insulation - it can be a rolled or bulk material. The next layer is placed only, on top of which once again make the crate.

The coating of the lonic roof with roofing material is carried out in the traditional way. To ensure ventilation to the roof, the poles are installed, then they are applied to them, on top of which the selected roofing material is attached. Since the broken roof simultaneously plays the role of walls for the attic, it is important to ensure a good climate in the room, and for this you need to respond with the choice of material for the roof. Iron sheets or copper tiles are unlikely to become an acceptable option, because, heating in the summer in the summer, such a coating will create too high in the room.

Creating waterproofs

Waterproofs are an integral part of the broken roof, as they help protect the walls and the foundation of the building from moisture and dampness. Do not equip the design by these elements, it is impossible to be sure that the house will serve you for many years. Create waterproofs can be from different waterproof materials, for example, from plastic, galvanized steel or non-ferrous metals. Metal structures are considered more durable and reliable, in the case of galvanized steel, it is also desirable that water-trailing is equipped with an additional coating that prevents the material damage.

Plastic structures are more fragile, but they are noticeably cheaper, moreover, they differ in a slight weight. Plastic waterproofs do not make characteristic noise with wind and rain, they are also represented by a wide range of colors, which allows them to enter them into any design. Modern plastic products also have a property to carry sharp temperature differences.

The most expensive, but also the most reliable option is the designs of non-ferrous metals. They are reliable, durable, not subject to corrosion, possess an attractive appearance. Unfortunately, due to the high cost, such waterproofs can afford not everyone.

Loan roof, photo: