Almost every repairs in the apartment or house there is a replacement of interroom doors. Thus, you can not only update the appearance and design of the room, but also improve its functionality. So, due to the fact that today there are a huge variety of different types of door structures, you can make a room visually more, fill it with the missing sunlight, transform the interior, etc. Next, consider how to choose an interroom door, for this we will get acquainted with the available types of structures.

Content

Varieties of interroom doors on manufacturing material

Choosing an interroom door, first of all, appreciate the following parameters:

- exterior of the product;

- its design and functionality;

- quality of the material from which the door is made;

- product price.

The material of manufacture the following types of door designs:

- wooden,

- glass,

- veneered,

- ekoshpon,

- laminated,

- plastic.

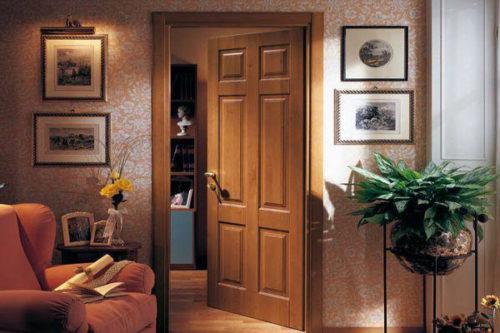

Interior doors of solid

Door constructions made of the following types of wood:

- Oak. The noble type of wood, its products get high-quality and durable. They have different color tinting. A feature of the oak is its tendency to darken the hue over time. This should be considered when buying oak products.

- Beech. Like the oak, it refers to the valuable species of wood. Products made of oak and beech have a fairly high price, but are of good quality and durability. Shades of the wood are predominantly light.

- Ash. Durable, but pliable type of processing wood. From it you can make the design of complex and curved shapes. It refers to the quality and reliability of solid wood.

- Maple. As ash is a valuable tree species, but it is slightly inferior to the price. Often customers prefer it to the wooden structures made of maple.

- Pine. Of all the species of coniferous wood, pine is the most high-quality and has a reasonable price.

- Spruce. It refers to the "budget" of wood types, respectively, and its quality is lower than that of other solid wood.

All wooden interior doors after their manufacture are finishing the process that improves their quality characteristics. Thus, their surface is covered with stains, protective structures, antiseptics and varnish.

The advantages of constructions of wood are:

- Beautiful and respectable appearance.

- Environmental cleanliness.

- Quite high strength.

- Interesting design.

- Good thermal and sound insulation.

Disadvantages of such products is also available. These include the following:

- Price.

- The sensitivity to temperature variations and humidity.

- Great weight of the product.

Today is quite popular steel products from laminated array. They are made of bars, consisting of layers of wood glued together joiner's glue. Products made of this material are cheaper than the door of pure solid.

Interior doors veneer and ekoshpona

The design of such products is rather complicated - their base is a frame of an array or MDF, glued from all sides of a thin plate of a veneer (compressing layer of woody array). Depending on whether the wood massif layer was used in the manufacture of interroom structures, the price of the product varies. As for performance characteristics, they are practically the same as at the door of the natural array. However, the weight of the product is somewhat lower than that of the doors from the natural tree.

EcoChpon can be attributed to the "budget" series of material. It is made of several very thin layers of wood (fibers) compressable, and glued with synthetic glue. These products refer to the combined interior doors, during the manufacture of which are used both natural and synthetic materials.

Advantages of Ecoshpon products:

- They have the same beautiful appearance, as well as products from a natural array.

- The doors from the ecosplan are resistant to moisture and temperature drops. They can be installed in such facilities as a bathroom, a bathroom and a kitchen.

- Do not lose your color when you get direct sunlight.

- Wear resistant, as the top is covered with a protective film.

- Have a relatively low price.

- Easy in leaving and in operation.

"Weak" part of the EcoChpon:

- Relatively low strength and resistance to mechanical damage.

- Low noise insulation.

- "Do not breathe" due to the presence of a protective film, so the room needs additional ventilation.

Laminated interroom doors

These interior doors have a relatively low price, so many buyers prefer them. Materials are made of the material "Laminatin", which is a layered and treated plastic.

Advantages:

- Such products undergo an additional finishing finish, so that their operational qualities exceed the qualities of PVC products.

- They are relatively resistant to mechanical damage, so they can be installed in rooms with high pendant people, as well as where there are small children or people with disabilities.

- Such designs are suitable for apartments and houses and for office space.

- Moreover, today there is a high range of such interior doors that differ in their design and color. Therefore, these products can be successfully add to almost any interior of the room.

The disadvantages include the fact that these products do not belong to environmentally friendly and natural. Their appearance may not be so noble as in interior doors from a natural massif.

Interior doors from PVC

Such products in office premises are quite popular, as they have a low price and good performance. They are made of wood bars, placed by polyvinyl chloride film. Consider more, the strengths and weaknesses of such doors. To the first of these, the following can be attributed:

- Low price. If you compare the cost of doors from the natural array and the price of PVC products, it may differ several times.

- Resistance to elevated moisture level. Such doors can be installed in bathrooms and kitchen facilities.

- Relatively resistant to mechanical damage - shocks, scratches.

- In the process of manufacture, the antibacterial processing step is passing.

- Easy in care. They can be wiped and washed even with the use of cleaning products.

Disadvantages:

- They are not so durable as products made of natural wood.

- Do not belong to environmentally friendly products.

Glass interior doors

As it is clear from the title, such products are made of treated glass.

One of the popular types of plexiglas is acrylic glass. In comparison with the usual material, it skips more light, is not so destruction, it is amenable to the necessary deformation, which allows you to create the necessary forms from it.

Plexiglas there are two species, depending on manufacturing technology:

- litea;

- extrusion.

Extrusion glass in comparison with casting has a number of advantages:

The sheets of glass taken with the help of an extruder may be greater length and less tolerances in thickness.

- Little needed effort and temperature for forming such glass.

- Best gluing ability.

However, there are some disadvantages:

- Great shrinkage when heated.

- Little impact resistance and chemical density.

- Great sensitivity to stress concentrations.

Interior doors made of glass have a number of undisputed advantages over the products made from other materials. They are achieved, first of all, due to the excellent physical properties of the material itself. We list the main advantages of such structures:

- Increased moisture resistance.

- Less training in comparison with products from ordinary glass.

- High strength.

- In the manufacture of the door, the glass passes additional processing. Sometimes it is sicked in layers, while getting triplex glass.

- Few material is compared with the plexiglass in terms of surface evenness.

- This is a pretty practical material. It is easily clean, it is allowed to use household detergents for its cleaning.

- May have a different type of surface - matte or glossy. There are also mirror interior doors that are distinguished by high quality.

The use of glass for the manufacture of doors practically does not have drawbacks. The only thing that can confuse when choosing this type of structures is its price, which is higher, in comparison with other products. However, aesthetic value and excellent performance overlap this flaw.

Varieties of interior doors in terms of opening-closing

Depending on the type of opening-closing, the following types of interroom doors distinguish:

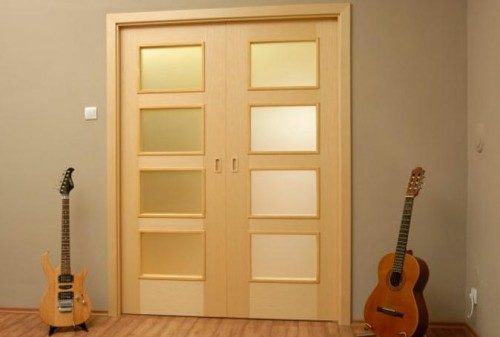

- Swing interior doors. This door design is most popular thanks to its simplicity. Such doors are opened by "swinging" and have one or two sash.

- Sliding interroom doors. These designs prefer to install in the rooms of a small area. When opening such doors, the useful area of \u200b\u200bthe room is not reduced. Exactly sliding doors for the kitchen, living room and hall. Unlike swing doors, sliding has one significant disadvantage, namely low sound and thermal insulation.

- Pendula designs. As it is clear from the name, such doors are opened by the type of pendulum both inside and out. Most often, such structures are mounted in public areas with high pendant people, for example, in the subway, shopping stores, etc.

- Folding structures. Their discovery occurs by the type of "harmonica". The existing "harmonica" does not take up a lot of free square square. Suitable for installation both in offices and apartments. Often such doors are installed in the dressing rooms.

- Rotating structures. Most often are located in public premises. The basis of the doors data is the static axis around which door flaps rotate.

Installing interroom do-it-yourself

Installing the interior door with their own hands in the following sequence:

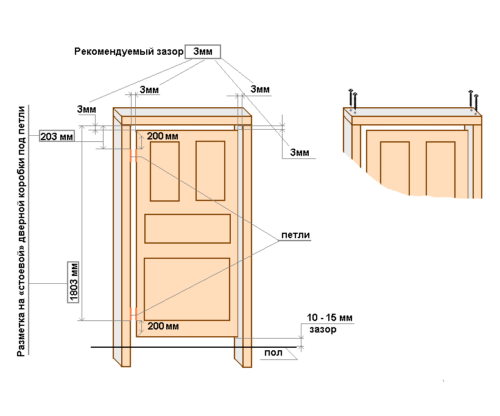

- Initially, all necessary measurements are carried out. Measure follows width, length and height of the doorway. These data are compared with the dimensions of the acquired interroom doors. If there is discrepancies, then the doorway needs additional processing.

- Next, the old interroom door is dismantled. If the integrity of the doorway was damaged during these works, then this should be corrected by applying plastering and cement. The correctness of the work is verified using the construction level.

- Wooden wedges allow you to pre-fix the door frame in the opening. When you set the design in the desired position, make marks for the placement of door loops.

- Then the door loops are installed on the door. Holes for them are made using a drill or screwdriver.

- When the canvas was installed in their place, all the gaps should be treated with mounting foam to provide the doors the necessary noise and thermal insulation.

- Next is the finishing processing and plants are installed.

Thanks for the useful and interesting article!

Often, many people have a question at the repair stage how to choose interior doors. After all, in any house, apartment or other room they are. In addition, they share rooms among themselves, they must also perform aesthetic function, and perhaps complement the interior of the premises: https://postroem-vse.ru/kak-vybrat-mezhkomnatnye-dveri/