In the process of installing a suspended ceiling, one of the most important steps is the installation of a metal profile frame. Using it provides the necessary strength of the structure. Also on the proper installation of the frame depends, whether irregularities and other flares will be present on the future.

Content

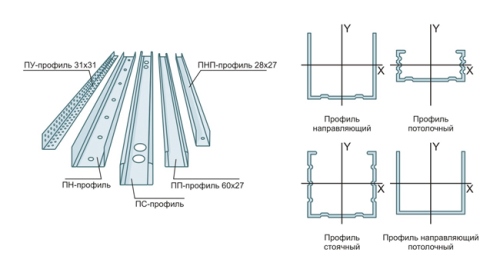

Metal profiles intended for the construction of the frame are usually made of galvanized steel, so that they acquire persistence to different conditions. They can be installed in almost any rooms, including with high humidity (bathroom, kitchen). In addition, they are well opposed with acid and fire.

Another advantage of metal products is their usability. They will easily cut and bend, thanks to which they acquire almost any shape. With the help of such elements, you can give any construct to the future ceiling.

In addition to the benefits of metal profiles, there are devices. First of all, the minus is quite high cost. But compared to other designs, the difference will not be very large. And their quality rather justifies the decision to pay more.

In order to make the installation of the ceiling frame on its own, it is enough to have a necessary material and tool. Before starting the performance of work, it is worth knowing that today there are several different ways to make markup and set to the ceiling of metal-rapid fastening. Each of them is suitable for different situations.

Methods for installing profiles

Method 1.The least expensive option for creating a frame for the future ceiling is a single-level ceiling without the use of suspensions (these are types P 131 or P 231). This method is also characterized by the smallest consideration. It can be used to finish small rooms, such as baths, corridors and toilets.

In this case, profiles should be installed on the walls throughout the perimeter of the room. As a result, a closed contour should be turned out. When this is done, in metal profiles with a certain interval you need to insert guides. The suspensions in this case are not needed, because the design is aligned with frame elements. It will help to save on materials. The result is a metal frame, which is ready for the fastening of the sheets of the suspended ceiling.

Method 2.The most common way to install the frame on the ceiling is a single-level type of fastening (these are Tips p 113 or P 213). This option is universal and suits almost any premises of different areas. Such a design will be needed with a suspended ceiling device located throughout the area in one plane. In this case, it is also necessary before the start of the main work, perform marking of the ceiling level. It must be marked on the walls of the room. After that, the profiles on the entire ceiling perimeter should be installed. Then you need to do the installation of suspensions that can be adjusted. After that, to these suspensions and to the frame, you should attach intermediate profiles with a certain step. The levels of the installed profiles are adjusted using suspensions. As a result, a metal framework should be obtained, which is aligned in the same plane. Then the ceiling must be seen with the necessary finishing materials. It can be a chipboard or hypostellular sheets.

Method 3.Align the ceiling plane in one or several levels can be used with a two-level ceiling using suspensions (corresponds to the types of P 112 or P 212). This method can be used to finish almost any premises. Moreover, it does not depend on the size of the design of the future ceiling and the conditions for its operation.

In this case, the installation of a metal frame on the ceiling is carried out by installing profiles in turns in different planes. It is not necessary that the frame elements are located around the perimeter of the room.

Fastening profiles to the base of the overlap is performed using special suspensions. In addition, with the help of suspensions, the level of solid is regulated. When profiles are installed, then they should attach the following range of frame elements. The result is the next ceiling plane. In this way, you can make a design from finishing materials consisting of two levels.

Mounting carcass

Preliminary preparation

One of the advantages of the arrangement of the carcass from metal products is that the acquired material that is necessary for work is immediately suitable for use. It does not require its pre-processing or adaptation to the climate of the room. Galvanized steel profiles are quite durable and not exposed to water, fire and microorganisms. They are not deformed at high temperature drops and change in room humidity. Therefore, as such preparatory work before their installation is not. You can immediately start directly to markup.

Marking contour

- The ceiling markup will be almost the same with all installation options. The same applies to the ceiling markup under the frame of the plasterboard. First of all, you need to find the lowest point on the surface. With a good eye, it is defined without any problems visually. But it is best to use the usual building level for this.

- At the level of the found point, you need to make a mark on one of the walls of the room. Then, from the mark made, it is necessary to retreat down to about the height equal to the height of the left interporal space. Thus, this value will be approximately equal to the distance from the basic overlap to the surface of the ceiling itself. It is worth noting that this value has a direct dependence on the thickness of the insulating plates, from the diameter of the communication pipes, which are planned to be installed, and on whether the lighting devices are embedded and what their dimensions are embedded. Do not forget also about the value of the weight of the suspended ceiling frame.

- When the height of the inter-station space is defined, it is necessary to make an indentation from the previously made mark of the lowest point. Then, from this mark we form a markup around the perimeter. From the new point you need to draw a horizontal line using a ruler, which passes through all the walls of the room, so that a closed loop is turned out. This circuit will be needed to be installed on the perimeter of the ceiling of metal profiles and to create the necessary benchmarks from the thread or wire that will be needed in order to align all the surfaces in one plane. Now the markup for a single-level ceiling is completed. The scheme of the frame of the ceiling made of drywall will look almost as well.

- For all other installation options, it is additionally required to calculate the step through which intermediate profiles will be installed and mark on the surface of the place where the suspensions will be attached. To do this, make the next sequence of actions.

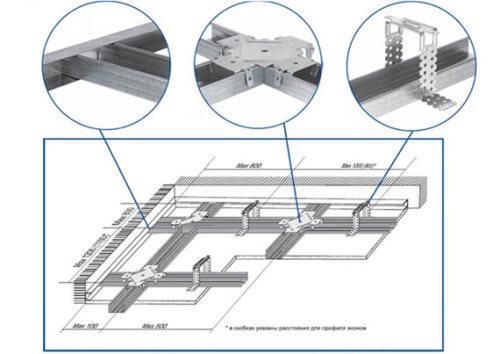

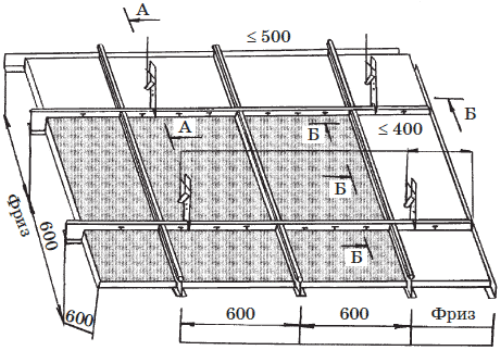

- First you need to choose, in which direction the main metal profiles will be laid, which must be perpendicular to the ceiling frame. The gap between them should be approximately 400-500 millimeters. The distance should be determined depending on the size of the material that is used to cover the ceiling. The profile step must be kept the length of the sheet. This is important for the normal docking sheets.

- Then on the surface of the ceiling should be applied parallel lines necessary in order to establish the main profiles of the guides. Between them should be the same distance as in the previous step. In this case, the distance from the wall of the room to the nearest profile can be a maximum of 800 millimeters.

- The main profiles should be based on a special suspension. Therefore, it is necessary to evenly apply the mark of the marks that will help install them. These lines should be located about 900-1000 millimeters increments. At the same time, the maximum distance to the nearest suspension should be 800 millimeters.

- Finally, you need to apply markup on the ceiling, which will help to install auxiliary profiles. They must be mounted perpendicular to the main guide. The result will be several parallel lines. Between each of them, depending on the type of system, is approximately 1000-1200 millimeters. In any case, the distance from the wall of the room to the closest profile should be no more than 100 millimeters. The surface of the ceiling will ultimately be drawn by lines. When it is ready, you can start equipping the framework.

Installing profiles

The order and scope of work that will be carried out in the future depend on the specific design of the suspended ceiling. For each method there are features and nuances. The fastest option on the assembly and installation of the frame is the installation of metal products by type P 131. In this case, you first need to install profiles around the ceiling perimeter. They are usually attached along the level of the horizontal line of the contour made earlier. When choosing thickness, the dimensions of thermal insulation plates should be taken into account. Directly profiles need to be attached to 500 millimeters with a screws. You can also use a dowel-nail.

- In order to protect the future framework from deformation, before installing profiles, stick to one of their sides, a special sealing tape whose thickness is 3.2 millimeters. Then we establish the guides of metal products, pre-enabling them to the required value. After that, it is necessary to connect profiles between themselves with self-draws. As a result, it turns out ready for further finishing framework.

- When installing ceiling profiles (P 113), they should also be fixed around the perimeter along the lines-contour.

- The difference in the installation of these elements is that the framework of PN 28/27 is already applied as the framework of the frame, which is established and fixed in increasing no more than 500 millimeters per wall with a dowel-nail or conventional screws. After that, you can proceed to the direct installation of the suspensions. In the event that the height of the erected interpostatic space is not more than 120 millimeters, then the P-shaped suspensions will be needed. Otherwise, you will need to use suspensions with clamps equipped with special knitting knitting. Places for installation of suspensions were defined earlier. These elements are fixed with dowel-nails and metal anchors with a spacer wedge. If the suspensions are attached to the overlap, then the sealing tape passes for sound insulation in the installation places. At the same time, the weight of the suspended ceiling frame (Armstrong, Dipline, Fran Studio, etc.) should be taken into account.

- Then all intermediate ceiling profiles are installed. At the same time, the first are the ranks that will be attached to the suspension.

- The profile is cut by scissors, and then inserted into the PN 28/27 element. After that, it fastens with the suspension with the help of self-screws or screws.

- If the length of the profile is not enough, then you need to take another element, dock it with the next profile and bore them with the help of special profiles 60/27.

- When the first part of the elements is installed, it is necessary to align them on the same plane. In order to be more convenient to align them to one level, you need to pull the rope landmarks at the level of the lines of contours.

- When all the framework elements are aligned, then you need to make them with the help of self-tapping screws. Suspension profiles are also attached similarly. After that, it will be necessary to establish profiles that stood perpendicular to the previously erected frames. When the material is cut to the desired size with scissors, profiles should be mounted in existing framework elements. As a result, one single ceiling plane will be obtained. All elements of the design with a perimeter are connected in a similar way, and they are bonded with each other using connectors. The result is a metal frame for the ceiling, which is later mounted wooden or gypsum sheets.

Installing profiles for a suspended ceiling with two levels is carried out almost the same as described in the previous method. The only difference is that the perimeter does not need to install profiles. First, suspensions are installed on the ceiling. Next, it follows in the suspension to insert the metall clamps, which must be pre-fixed. Then with the help of stretched landmarks from the rope or wire, it is necessary to align the entire frame on the same plane. After that, profiles should be finally copped with suspension with self-tapping screws. Thus, the construction of the first level of the ceiling frame level is performed.

Now you need to mount the second level of profiles. In this case, the second number of items should be installed directly to the first, which was mounted earlier. To do this, you must first fit them under the desired size with scissors. Knowing the installation step, which was calculated earlier, profiles should be reduced to the existing elements so that their rows in different planes form a straight angle. After that, they need to be copped with each other with special two-level connectors. The result is a metal ceiling frame, ready for further finishing.

After mounting the frame of the ceiling of drywall, work is carried out on laying of wiring, communications, thermal insulation and sound insulation. Then the ceiling is coated with sheet material.

Installation of electrical wiring for lamps

In the case of placing luminaires, electrical wiring will be required. If there are ten or more lamps in the plans, they need to be connected by groups, while creating comfortable lighting zones intended for the implementation of various kinds of work. Thus, for each room area there will be its own switch. If you connect to one, you will lose many advantages. All wires should be put in special cable channels and arrange them inside the design in such a way that they are away from profiles and screws. Next to the wire lamps need to be left so that they can be obtained through a hole carved for each lighting element. At this stage, the installation of the cutting frame is completed.