The roof, like the facade of the building, is its "business card", and therefore should be not only functional, but also beautiful. Installation of roofing material The installation of the roof will not end. The fact is that the remaining distance from the edge of the roof to the wall of the building forms a huge gap. Through it, dust, moisture, to fly the birds can fall through it. In addition, she is not very aesthetic in a pair with cereal rafters. Correct this situation can be installation of soffits. About how to install sophifes with your own hands with detailed instructions, let's tell later.

Content

What is sophyte and what they do

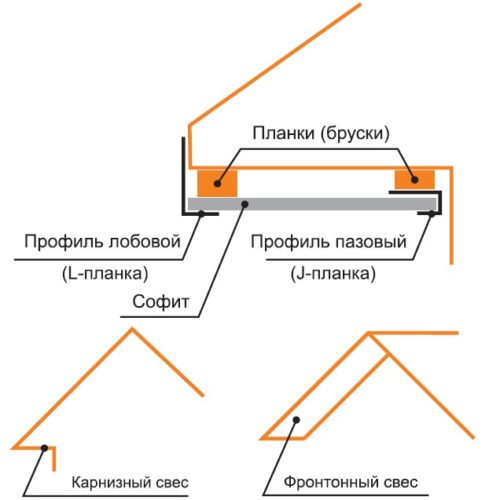

Sophytes - elements of the sheath of the bottom of the roof. They close the lower part from the harmful effect of atmospheric phenomena, insects and birds, and are also an element of roof ventilation. Currently, industrial sofa is made from various materials:

- Vinyl. Vinyl sofites are characterized by their ease. The small weight of the material does not require the installation of a massive frame crate. In addition, it has antibacterial properties. On the surface of the vinyl, the fungus and mold is not formed, which eliminates the constant care for it. According to the cost, this material can "give odds" to almost any sofam, which makes it very popular not only to cover the roof of a residential building, but also for roofs of garages or other buildings. It is very simply processing and installing, so the installation of plastic sofita can be made with their own hands. The disadvantages of vinyl can be attributed to the fact that when heated it can make an unpleasant smell, but it is worth noting that it belongs mainly to cheap material. Also, this material supports burning.

- Cink Steel. Of these sheets, the roof coating is made. They consist of directly steel sheet, which is covered with polymer layers, and paint. Thanks to this, the sophods from galvanized have high strength, serve quite a long time, do not support burning, easily mounted. However, the disadvantage of these models is their relatively high weight, so the installation of metallic sofit requires the installation of a powerful frame.

- Wood. Wooden lining is often used to cover the roof. This is an environmentally friendly material that in its beauty can compete with almost all others. Natural wood heat makes the facade of the building very cozy. The disadvantage of natural wood is that it is very subject to environmental impact, and also requires constant care. Without it, wood can be contrary or damaged by insects. Moreover, in comparison with plastic, or vinyl, the cost of the tree is much higher. Currently, we are increasingly resorted to the installation of a wood composite, which in its composition has natural wood of deciduous rocks and polymer materials. Due to this, the performance characteristics of such sofites grow at times.

- Aluminum and copper. These models are quite expensive. They are not subject to corrosion, have a small weight, but at the same time they have good strength. Even without additional processing, they look beautiful. However, the cost of these models is very high. In addition, they need to attract specialists for their installation.

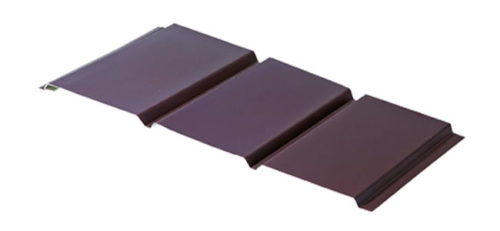

Sophytes, in addition to the material, from which they are made, are divided by their texture on:

- Solid. The panel does not have holes and absolutely deaf.

- Perforated. The panel has holes in the form of perforation.

- Combined. The panel on the surface of the surface has perforation, and the part is deaf.

- Combined panels are most popular. They are not too open, but allow you to carry out the rafting roof system.

When choosing Sofita, it is very important to draw attention to the quality of their execution, as well as on color. It is better to try to buy alone party products. Then the color will be the same. For the same reason, the amount of material for procurement is calculated taking into account the 15% reserve in case of damage.

Technology of installation of sophods do it yourself

The covering of the undercase space with sofits is not a complex process. When possessing simple mounting skills and a set of simple tools.

Basic principles of Sofita Installation Technology:

- Installation of the trim is carried out on a pre-installed cladder for sofa, which is made from a wooden bar or galvanized profile. The latter is distinguished by more reliable characteristics, so it is better to use it. If it is planned to install a tree cage, it must be previously treated with oil and an antiseptic. Otherwise, its service life will be short.

- For fastening panels to the profile, stainless steel screws are used. The usual self-tapping screws will start rust over time, which will lead to the appearance of rust spots on the trim.

- When installing sofits, some simple rules must be observed:

- The installation is carried out at an ambient temperature of at least + 15 ° C.

- Before starting work, the material lay out the outside so that it gains normal temperature and humidity. Otherwise, when heated or cooling, it can change its dimensions that is not very good.

- Reiki for fastening sofitions should be located parallel to the walls of the task.

- The distance between the plackets of fastening of sofites should be no more than 400 mm.

- The first and last profile or bars are installed close to the edge of the roof and the wall of the building.

- The width of the sofit panel must be slightly less than the distance between the supporting profiles by 5-6 mm. This will give the material to expand when heated.

- The frontal board of the roof is always sewn with deaf sofit, the lower plane is perforated or combined.

Step by step installation of sofits with your own hands

For this paper, you will need the following materials and tools:

- Electrode or perforator.

- Electrolovka.

- 4x40 fast mounting dowels for fastening a J-profile to the wall.

- Self-tapping screws for fastening a J-profile to a frontal board or other wooden roof elements.

- Sofita panels.

- J-profiles.

- Level, roulette, line.

Procedure for work:

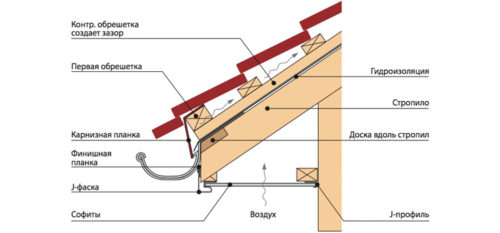

- Installation of sofit from installing a J-profile on the end of the front board. It is necessary for fastening the horizontal Sofita strip. When installing, it is necessary to ensure that it is installed in terms of the level. The distance from the wall to the profile attachment point should be the same along its entire length. To control use level and roulette. A j-profile is attached to the frontal board of the roof using self-samples with a step of 300-400 mm. To do this, it is better to use an electric jourver.

- After the installation of one profile is mounted, a used J-profile is mounted. Shelves of profiles on which Sofit will lie should be on the same level. Therefore, the markup to the installation of a used profile must be done under the already installed profile in the end of the front board. To do this, use the level. A j-profile is attached to the wall with fast mounting dowels. The profile is applied to the wall on the applied markup, using a drill through a hole in which a dowel is inserted. After that, a nail is clogged into it. Installed fasteners with a step of 400-500 mm. Now profiles for the binder of the lower cornice are ready.

- Next, you can start setting profiles to cover the frontal board. It also features 2 J-profiles: lower and top. The top is mounted in such a way that it goes under the edge of the roof, and the bottom to formed with the forward angle with the already installed horizontal profile. Installation of J-profiles for the firmware firmware is carried out using self-samples.

- When installing sofits, it is necessary to remember that the joint between the stripes should not "hang" in the air. That is why, knowing their length, it is necessary to establish the studders, or profiles.

- To cover the lower part of the eaves, the combined sofit is used or perforated, and for the front board binder - the deaf model. The width of the standard sofit strip is 400 mm. Therefore, if the distance between the guide j-profiles is more than 406 mm (6 mm per thermal expansion), an additional plank is installed between them, on which 2 bands are joined.

- If the distance is less, the sofit can be short. At the edges of each panel there are locks, thanks to which they are joined with each other.

Installing Sofita does not constitute anything complicated. The panel starts the end part in one profile, and then to another. The end of the panel is attached to the transverse bar with self-draws. The next plank is then installed, which is inserted with the previous one with a special lock.

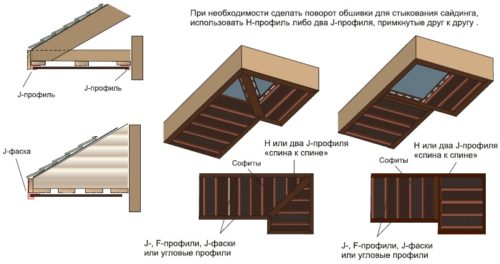

Special attention should be paid to the installation of sofit in the corners. There are two ways to dock sophytes in the corners:

- Direct installation.

- Diagonal installation of sofits.

And in that and in another case, the docking of the panels is carried out by connecting two J-profiles with rear walls. With a straight docking, the joint is on one of the sides of the binder, with a diagonal - in the middle of the angle. The second method is more complex and time-consuming, however, the result in this case is more interesting.

Errors when installing sofit

As a rule, when conducting these works, mistakes are quite difficult. However, they meet. The main ones are:

- Poor or uneven fastening of the guide profiles.

- Lack of technological gap.

- The absence of additional fastening in the location of the panels.

- The absence of an additional profile in the case of a karnis width of more than 400 mm. True, it must be remembered here that in places with strong winds it is necessary to install an additional profile in any case.

All these moments may affect the operation of sofita, so it is better to do everything right right away than to redo after a while.