Attracts the view of the house, the facade of which is not similar to hundreds of others, where the individual is present, only him inherent in the raisin. Moreover, I want to look like this house, erected personally. This idea is easy to implement, using the advantages of mounted ventilated facades, which not only look beautiful, but also make the house comfortable. We will tell you how to mount the mounted ventilated facade with your own hands.

Content

What does he represent

The main components of the hinged ventilated facade are:

- Facing or screen. This is not only a beautiful shell, but also protection. It is plates:

- from porcelain stoneware;

- terracotta;

- glass;

- HPL - plastic compressed paper-layered;

- from the natural stone;

- fibro cement;

- from Planken, i.e. Natural tree;

- composite panels multi-layered;

- siding;

- aluminum, copper and steel metal and steel can also be used.

- Aerial gap, which is formed between the protective screen and the heat insulating material. Because of its presence, the facade is called ventilated. It gives a lot of advantage of the facade of this type in front of the facades traditional.

- Heat insulation, which is plates from mineral wool, protected by a special membrane.

- Substructure. This is what cladding is attached. It includes:

- Brackets, with which the facade is attached to the wall of the house;

- fasteners;

- bearing profiles made of stainless steel, aluminum, steel galvanized.

All pluses

When choosing an attached ventilated facade for your home, you will have a lot of positive:

- you will be able to implement the most courageous design solutions and your facilities will have a beautiful view, because It is possible to use a large range of materials in the widest color scheme, a variety of shape;

- the ventilated facade, the installation technology of which involves the use of light and at the same time, reliable aluminum profiles is the possibility of implementing the set of options inaccessible when choosing more familiar home finishing methods;

- you get the opportunity to give a presentable view to your even strong, but looking old-fashioned home for relatively small money. It will increase its life;

- the mounted facade in case of contamination can be simply washed;

- if you want to warm the house additionally, then it also provides for the possibility;

- walls "Breathe", do not absorb moisture;

- reduced heating costs;

- installation work does not need to postpone for warm times. They can be performed anyway;

- materials from which hinged ventilated facades are manufactured, environmentally friendly.

Mount the ventilation facade yourself. Mounting scheme

All construction firms in need advise to hire a ventilated facade of specialists for installation. Professional is good, but it is not always possible to take advantage of its services. To be upset about this should not. We will look at the ventilated facade, the installation scheme of which is available for self-execution.

Tool

It is necessary that you have a set consisting of:

- metal scissors;

- screwdriver;

- rivet ticks;

- plunder;

- roulettes;

- marker;

- level.

Technology

Any work will be performed better if there is a clear plan. In the case of a ventilated facade, technology and its phased performance is crucial:

1. If there is no project of the ventilated facade, then sketch the scheme yourself, which you will follow.

2. Having a circuit, we make marking on the walls where we mark the locations of the brackets. Moving at the bottom up. It must be remembered that the bracket should not fall on the seam of the masonry.

3. In the marked places we drill holes whose depth is 1 cm more fastened. Install brackets using anchor for this. Wherein:

- the connection will be more reliable if the anchor is secured through aluminum washer;

- at the end of the operation, we apply paint on an anchor hat as rust protection.

4. When choosing an anchor dowel, it should be considered from what material the wall is made. If it is concrete, stone or brick, then the anchor should have a metal sleeve. Plastic sleeves are chosen for samanny walls, shells.

5. Getting styling insulation:

- in places where the bracket console falls, we carry out cutters;

- we do not allow the gaps between the wall and the insulation;

- if these are plates, then we place them in a checker, as close as possible to each other;

- solid joints are not allowed;

- to secure the insulation, we use special dowels from plastic, which have a plate shape;

- furnace insulation fastener is impossible;

- there should be so many dowels for each slab as the manufacturer recommends;

- the length of the dowel will determine the calculation. We will add a depth to the thickness of the heat insulation to which the dowel should be included in the wall.

5. On the insulation, we apply moisture and windproof film:

- now proceed to the installation of the guides. Confirm them to brackets. The brackets themselves are different;

- in some guides are inserted into the grooves that are available in the shelves, aligned vertically, then fixed by using facade rivets or screws;

- another type of brackets is designed for a preliminary attachment of the brackets to the movable part for the levelation. After, part of the bracket is connected to the main - fixed;

- where guides are joined, leave 1 cm gap, because In the warm time, the material is expanding.

See how the fastening of the guide of the ventilated facade, the installation technology, the photo, posted by us, passes into the details and will help perform everything without disorders:

We establish angular elements and framing openings:

- we do not forget to leave a gap between nachets in 1 cm;

- knot fastened two rivets;

- fastening the planks along the perimeter of slopes of door and window openings with the involvement of vertical guides. The distance between the fasteners is at least 40 cm. Frame is first collecting, and then we are looking for the opening.

Now it's time to start a frame facing. Installations of the ventilated facade, video:

Installation of the ventilated facade of metal

When choosing the installation technology of the ventilated facade, the price of the cladding plays a considerable role. Most often on the basis of considerations of savings, siding use. The leading place in this respect is occupied by vinyl, but applies a metallic, having a number of advantages:

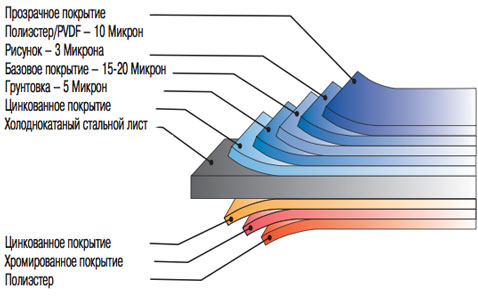

- maximum mechanical strength. It is well opposed to shocks, all sorts of atmospheric influences. It is a steel profile cold-rolled. Top layer zinc. It can also be made of aluminum alloys. The maximum thickness of the metal kernel is about 0.65 mm, and then a number of other layers. As a protective coating, polyester matte, pouranel, plastisol are used. Applying the latter, get all kinds of textures;

- resistance to aggressive substances provide him with high-quality primers and varnishes, innovative technologies used in color;

- resistance to the effects of fire;

- environmental Safety. Plastics, resins, chemicals in production do not apply;

- going to easily like a children's designer;

- not subject to corrosion;

- durable;

- aesthetic;

- absorbs noise up to 20 dB;

- well behaves at a temperature of +50 to -50 degrees with;

- differs in a wide range of gamut;

- manufacturers produce a metal siding siding and covered with a patina or plastic;

- it is possible both vertical installation option and horizontal;

- metallosing has a special edge where fasteners and lock is installed, so the design is stable. On the lower locks there are holes through which condensate is given.

As disadvantages it should be noted:

- that he is heavy, although aluminum, of course, is much easier than steel;

- at a cost exceeds vinyl analogue;

- lack of flexibility;

- installation of steel siding is possible only for a metal profile, and both under aluminum and vinyl siding can be arranged wooden frame.

Metal types

Metallising is available in the following types:

- classical. Looks like vinyl, smooth coating. Many color variations;

- decorative. Imitates natural and artificial surfaces;

- facade, base;

- horizontal, vertical;

- entitled "Shipboard";

- with insulation.

Heaters for ventilated facade from metal

By installing the ventilated facade of siding, it is better to use one of these materials as the insulation:

- basalt or mineral wool. Moreover, this insulation must be isolated by the film twice - from the wall to protect it from wet evaporations that leak through the walls and before mounting siding, because there may be condensate;

- polystyrene foam, extruded density at least 25 kg per 1 cubic meter. m. This insulation is the most practical, because It does not affect moisture and it does not need any additional protection. It is true, more expensive than the thermal insulation from the wool.

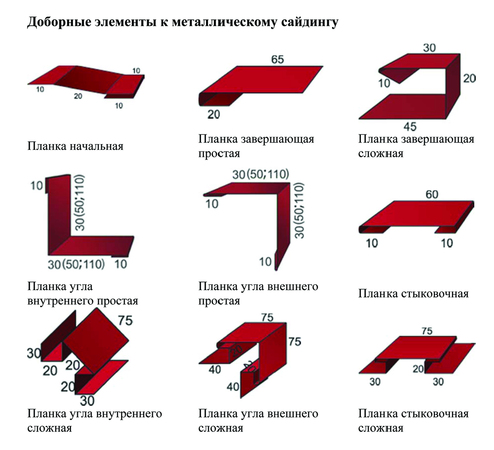

Dobly elements

Installation It is impossible to perform without good items:

- simple and complex indoor corner;

- outer corner;

- N-rail;

- platband;

- reiki invoice;

- rake initial and finishing;

- motion.

Two ways to install a mounted ventilated facade of metal

Metal: mounted in 2 ways:

- with the use of visible fastening, which is relevant for a simpler profile. The essence of this method is that the edge of the panel below is overlapped with a side panel. This 100% prevents moisture from entering. The mount is carried out using visible rivets;

- hidden, where hooks are used. The panels themselves are distinguished by a complex profile, which has a lower and upper bending with a bevel at an angle of 60 degrees. The feedbacks of the adjacent panels engage for each other and the gap decreases, the fasteners are covered. This facade has a very beautiful view.

Observe the basic requirements:

- for good functioning, the space between metal lining and the insulation material must be at least 4 cm;

- the whole doom on the wall must lie in the same plane;

- mounting the ventilated facade of metal: nail the starting bar below;

- siding must be fastened freely and in no case. The gap between adjacent canvas is from 0.3 to 0.9 cm;

- for cutting metal, an electrolybiz or saw disc is suitable.

Application

Some time ago, metalyding was used only for the device of ventilated facades of administrative and industrial buildings, multi-storey houses, and now it often began to be used for lining of private buildings.

Best Metal Handing for Attached Facudes

A very high-quality metalying enters our market from Finland, produced by Ruukki. These features are the facade panels Lamella Groove 20:

- height - 15 - 30 cm;

- width: 15 - 300 cm;

- profile depth - 4 cm;

- the thickness of steel is 1.2 mm;

- aluminum 1.5 mm;

- hidden fastening.

The domestic metal is characterized by lower price and almost the same quality. It is highlighted by the quality of metallicising from the domestic manufacturer Holding INSI. Here in the photo you can see the composition of the panel, the basis of which is a steel sheet:

But all told on the video: