Today, the construction industry offers a wide range of materials, with which you can make a facade of the building. One of them is facing brick. His main difference is decorative qualities. Preferably, this material is used for the outer decoration of buildings, however, in addition, it is carried out with it to fit the various surfaces indoors, for example, columns or fireplaces. Facing masonry requires maximum accuracy and a neat approach. This process is more time-consuming than working with ordinary bricks. Consider all the details of working with such material in this article.

Content

Varieties of bricks

The main task of bricks for cladding is the decorative design of the facade. But along with the aesthetic properties, this material has both practical qualities. Facing protects the building from the negative impact of atmospheric precipitation.

Facing brick is divided into two types:

- full-time;

- hollow.

If you compare the advantages of the presented types of products, then there are no more of them from the hollow brick:

- This material has good thermal insulation properties.

- Also, due to the presence within the brick, it has a relatively low weight.

- When cladding the building with hollow bricks, the load on the facade will be minimal.

- In addition, such a brick is easier to transport.

Among the advantages of a full-scale facing material can be distinguished only by its good strength.

In addition, there is a classification by the method of production. Depending on this, the criterion distinguishes:

- clinker;

- hyper pressed;

- ceramic brick.

Consider the features of each of them in more detail:

- Clinker brick on external characteristics resembles the usual type of product. Such products are distinguished by special production technology, because A special clay is used as a raw material for its manufacture.

Its main properties are strength and wear resistance, so this brick is used in the presence of large loads. For example, when designing base, as well as door and window openings. In addition, clinker facing is characterized by minimal absorbing qualities, structure density and good heat-conducting indicators. Due to these characteristics, clinker brick can be used both for external and interior decoration.

- Hypersed brick. The basis of the manufacture of this material is the principle of exposure to high pressure. The firing in this case does not apply. Also, the brick of this type is characterized by a chemical composition. With its manufacture, it does not apply clay and sand. Brick contains cement composition, pigment and crushed limestone.

The material has a visual similarity with a natural stone, has high wear resistance. If necessary, this brick is processed, while all its positive properties are saved. Hypersed brick does not have a high thermal insulation capacity, but this situation can be corrected using insulation.

- In the process of producing ceramic bricks on its outer side, a layer of liquid ceramics is applied. This allows you to create various embossed images and drawings. With the help of a special composition, glazed bricks are manufactured. The glaze gives the material with special aesthetic qualities, making bricks volumetric.

Requirements for material

High-quality lining brick must comply with the following requirements:

- First of all, there must be absolutely even ends and angles. The quality quality indicator is the outer side of the brick. It should be missing any deformation changes and chips. Deviations are allowed in size via width - to 3, mm, in length - up to 4.4 mm and in thickness - up to 2.3 mm.

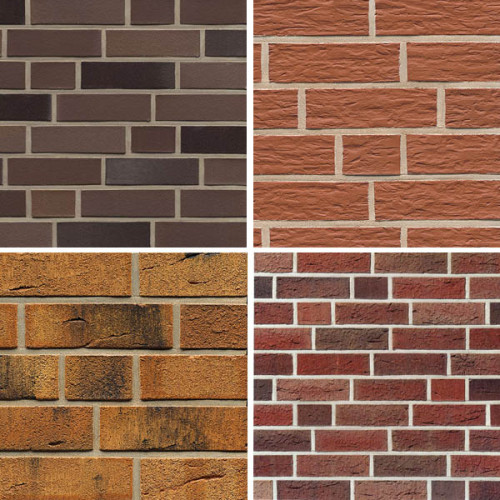

- The outer side can have both smooth and relief foundation. To date, there is a rather extensive selection of brick color solutions for cladding. Along with standard red and yellow colors, the building market offers a variety of color solutions, which allows you to embody any designer project.

- According to its size, standard facing brick must comply with the following parameters: 250 x 120 x 65 mm.

- The dimensions of the narrow facing brick should be 250 x 60 x 65 mm.

- Thickened brick must correspond to the size of 230 x 107 x 65; 250 x 107 x 65; 250 x 120 x 88 mm.

Criteria of choice and recommendations for laying

To purchase high-quality products that will last long time, such aspects should be taken into account:

- In the process of choice, it is recommended to give preference to the manufacturer who has already been operating on the market for a certain time, and has established itself from a positive side. When buying, you need to get acquainted with the product quality certificate. At the moment, the products of foreign manufacturers are more in demand. The cost of such a brick is 1 euro per piece.

- Laying bricks of facing in its technology resembles the laying of ordinary brick, but at the same time there are some features. Before proceeding directly to the process of facing, it is recommended to lay out them dry. This will provide the ability to detect material inappropriate sizes if there is such available.

- To give bricks the required parameters and shape should be used with a grinder with a special disk designed to work with a stone. It is definiciently impossible to use a disk for this purpose to work with the metal. Also do not adjust the brick parameters using a hammer.

- The solution for facing masonry is prepared on the basis of sainted sand, cement and water. Sand is desirable to use fine-sided with a small content of clay. This mixture will differ in color from bricks. In order for the solution to acquire a characteristic shade, a special color composition should be added to it. You can also purchase a ready-made composition in a specialized store already painted in the desired color.

It is not necessary to prepare a cement mix in large quantities, since it cannot retain its properties for a long time. It is recommended to prepare the composition of small portions.

- During operation, the solution should be applied at a distance of 1 cm from the edge of the brick. To do this, you can use a special template. The consistency of the cement formulation should be thick, in the opposite case, the material will be shifted. You can move bricks until they grabbing with cement makeup. In the event of a solution from entering the outdoor side, it should be cleaned immediately, without waiting for the drying of the mixture. If the mixture is able to dry, clean the brick will be quite problematic. For cleansing, you can use a wet rag or sponge.

With a qualitatively made cladding of the seam on the outside, one should not perform by more than 2 mm. The width of the seam should be 10 mm, and the thickness is 12 mm. To ensure air access to the wall, each fourth vertically located seam located in the bottom row is not necessary to fill in the cement mixture.

Types of masonry facing brick

Highlight three main types of masonry:

- Direct laying is performed using any ligament method. Sews in this case are distributed evenly, one by one between the rows.

- Decorative laying. It is based on a variety of drawings, the seams are formed by a specific scheme. It is possible to use multicolored bricks.

- Artwork. From the decorative species, this type of masonry is characterized in that, along with the scheme of seams and the color of the material, it is also necessary to adjust the process of laying.

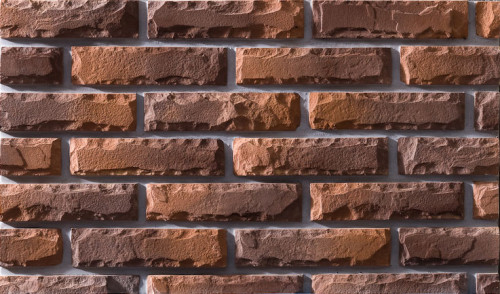

Laying of facing bricks. Photo:

Direct Facing Masonry Technology

Tools that need to be prepared for work:

- concrete mixer;

- trowel;

- plumb;

- forests;

- buckets;

- hammer;

- level;

- rod with a round cross section with a diameter of 10 cm;

- pntach with square cross section.

Facing masonry can be carried out simultaneously with the construction of the construction or after a period of time. Consider the masonry method after completing construction.

- The initial stage of the work is the leveling horizontally base with a solution.

- Next, the perimeter lay out bricks. The first layout is carried out without the use of cement mixture. This is necessary in order to identify problem areas. In case of detection of irregularities, bricks need to be cut.

- The ranks need to be positioned so that they do not interrupted in the area of \u200b\u200bdoor and window openings. For applying the composition use templates for facing brickwork.

- After laying the first row of cladding on the base, the next step is to process the corners. First, bricks are stacked in places of angular compounds, after which rows are formed between them.

- Over each nearby you need to stretch the thread so as not to go beyond the level. So that the seams between the bricks turn out to be even, the square twist should be used during operation. It stacked on the edge of the brick, then a solution is applied at some distance from the pntach, after which the brick is installed. To do this, the briquette must be hit by a hammer until the touch with a rod occurs.

- To avoid destruction or displacement of the structure, as well as the formation of cracks, you must perform binding to the wall. This will require dowels and well-bending knitting wire.

- The work is performed in the following order:

- first, a dowel must be scored in the wall (in this case, 6-ka is used);

- then, to a dowel cap, you need to fasten the wire, while in length it should correspond to the width of the brick;

- wire ends should be placed so that they are located inside the masonry;

- binding must be made through 4 rows height and 60 cm in width;

- in order to achieve high-quality insulation of the room, you should not put the solution into the space between the wall and masonry.

- In the places of window and door slopes, the masonry is carried out by the Pickle in one brick. In the process of the masonry, the seams are also performed, after which the seams should be filled with a cement mixture and lure with a round twist. At the end of the work, the facing need to wipe with a dry rag.

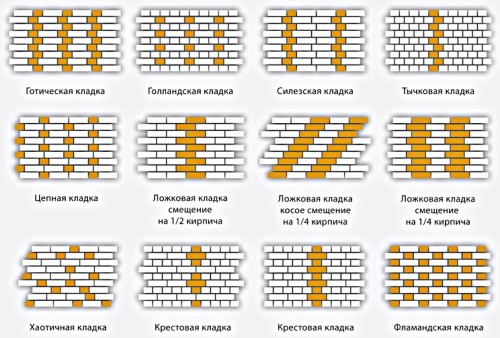

Options for decorative masonry

Consider the most common variants of decorative masonry:

- "Block" method provides for alternate laying of long and short sides of the brick. In this case, it is necessary to ensure that the joints are placed vertically one over the other.

- The "track" variant is characterized by laid out the material with an extremely long side. At the same time, during the work, bricks in all subsequent rows need to be shifted by a quarter or half.

- When performing the "Brandenburg" masonry, the material needs to be recorded in the following sequence: first two bricks with long sides, then one - short. So bricks should be changed in all rows.

- With the "Gothic" laying briquettes alternate in each row long and short parties. The joints in the first row should be shifted to a distance equal to half bricks with its short side. In the subsequent row of joints are placed on each other.

- The "Dicking" method allows you to have bricks with long and short parties in any order. It provides the ability to create a unique pattern.

- "Cross" laying allows you to get a cruciform pattern. This method provides for the alternation of long and short sides of the bricks, but at the same time it is necessary to shift the joints in half the length of the brick.

Today there are many laying options. The above methods can be taken as the basis and create original facades by changing the color and thickness of the seam.

Conclusion

The laying of facing brick allows you to solve two tasks: make the appearance of the facade more attractive and reduce the negative impact on the house of precipitation. To date, the construction market offers a wide range of this product. Bricks differ among themselves by texture, color, production method. Working with this material has its own characteristics. To get high-quality cladding, laying must be performed with great accuracy and accuracy.

Laying of facing bricks. Video: