Housing insulation with their own hands is more likely to be a tribute to fashion. With the increase in the request for people to the useful housing area and a significant increase in the cost of energy, the problem of the cost of heating for the house has become pretty acute. To reduce heat generation and save fuel, you need to take care of the minimization of heat loss. It is for this that the facade and other structural elements are insulated. On the pros and cons of modern materials, as well as about the brief review of their characteristics, let's tell later.

Content

- How to insulate the walls of the dwelling: outside or inside?

- What you need to pay attention to when choosing a material for housing insulation

- Materials for outdoor housing insulation do it yourself

- Materials for insulation floor housing with their own hands

- Materials for internal housing insulation do it yourself

- Features of the insulation of country houses and cottages with their own hands

- Materials for housing insulation do it yourself: video

How to insulate the walls of the dwelling: outside or inside?

Many owners before starting the insulation of their house, asked how to do it. After all, it is possible to warm the inner surfaces of the walls, which in the conditions of a multi-storey building is much simpler. However, many owners of apartments and houses give their vote for the insulation of the facade, confirming this by the unconditional advantages of this method:

- Useful room area. With the insulation of the facade, the inner volume of the premises will remain the same, and this is very important. The size of 5x5 meters in size with a foam-thickness of 100 mm will lose about 1 m 2. It's a lot or a little, solve everyone.

- Convenience of mounting. Outdoor insulation will not affect the usual way of life. It will not be necessary to free the room from furniture, to carry out repair, which will greatly facilitate the process of insulation. In addition, frameless insulation requires the use of dry building mixes, which will lead to a significant amount of dirt indoors. With outdoor insulation, all these problems can be avoided.

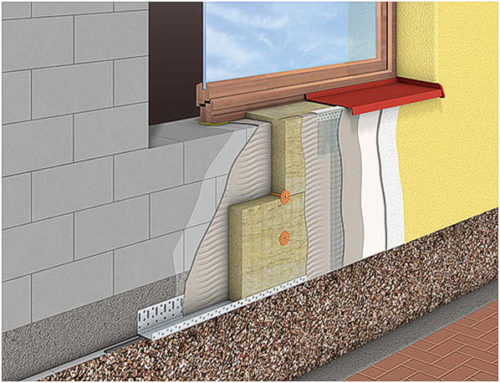

- Displacement point dew. With outer insulation, the dew point shifts to the insulation, which favorably affects the state of the walls that are not exposed to temperature drops. Otherwise, the walls begin to crack over time, they are formed slit. If the walls are made of wood, they can start rotting that violates the integrity of the whole design.

- Battery heat. In the facade method of insulation, the wall of the building receive the effect of heat accumulation, thanks to which the house cools slower. In addition, facade insulation will protect the house from dampness, which often occurs when the temperature drops.

- Appearance facade. After insulation, plaster and painting, the facade will play new paints by making the appearance of the house more attractive. When performing external insulation, you can use any materials that favorably distinguishes it from internal works.

What you need to pay attention to when choosing a material for housing insulation

When choosing a material, it is necessary first to pay attention to its operational characteristics:

- Thermal conductivity. This is the most important insulation indicator. It shows the ability of the material to carry out heat. The lower the thermal conductivity of the insulation, the more heat he can save inside without passing it out.

- Refractory. Shows the ability of the material to resist fire. The insulation should not support the burning, and even more so, self-propagation.

- Gigroscopicity. This indicator determines the ability of the material to absorb moisture. The less hygroscopic material, the smaller he has thermal conductivity. The fact is that molecules in the liquid medium in the presence of moisture in the insulation are much closer to each other than in the gas, and this, in turn, increases the thermal conductivity. Increasing the humidity of the insulation in just 1% increases its thermal conductivity by 25%. That is why the material must have practically zero hygroscopicity. Otherwise, on the surface of the insulation, it will be necessary to lay a layer of waterproofing.

- Chemical and biological stability. Shows the ability of the material to resist the harmful effects of chemicals and various microorganisms.

- Air permeability. The ability of the material to ensure air movement between the surface of the walls and the environment. This is a very important indicator. The better the air permeability, the less likely the accumulation of moisture between the insulation and the wall.

Materials for outdoor housing insulation do it yourself

For the insulation of the external surfaces of the building walls, a wide range of materials is used, each of which has both its advantages and disadvantages. The use of any insulation depends on the characteristics of the building, the material possibilities of the hosts of the house, the features of the installation.

Consider the most popular materials for outdoor insulation.

- Polystyrene foam (foam). This lightweight material has a fairly low thermal conductivity coefficient, it is not very expensive, easy to install and has a long service life. Due to this, the polystyrene foam has become the most popular material for insulation not only private houses, but also multi-air height. Due to its structure, polystyrene foam can be laid in a frameless way, which simplifies the installation process, and makes it much cheaper.

The process of mounting foam plastic on the wall is very simple. It is placed on a special glue, after which it is additionally strengthened by a dowel with a wide hat. After that, a reinforcing grid is applied to the surface of the foam, and then plastered. The fact is that exposure to ultraviolet is very much like exposure to ultraviolet. As a result of a long stay under the right sunlight, he just begins to crumble. Plaster protects foam from external influence. Currently, the technology of using polyfasada has been quite popular. In this case, the polystyrene foam is made with a decorative layer (decorative tile). Thanks to this additional plaster and painting such a facade is not required.

The disadvantage of polystyrene foam is that after a while it is necessary to update the plaster and painting of the facade.

- Basalt mats. They have greater reliability than polystyrene foam, serve significantly longer. However, the cost of mats and their weight is great enough. The weight gives an additional burden on the foundation of the building. That is why it is better to provide for the likelihood of such insulation at the construction stage of the house.

- Mineral wool. Easy and very warm material. It is he mainly undergoing the device of ventilated facades. For mounting mineral wool, a supporting frame is required, and for its protection against moisture - moisture protection layer. As an finishing coating on mineral wool, lining, siding or composite panels are used. The ventilated facade is the most expensive type of insulation, however, he has much lower thermal conductivity, and the service life longer. When using siding or composite panels about the repair of the facade, you can forget for a long time. Mineral wool does not support combustion, resistant to the effects of a chemical or biological environment. This insulation is produced in the form of mats or rolls. Mineral wool is one of the most popular materials for insulation of frame wooden brick panel houses with their own hands.

- Polyurethan. This material is relatively recently appeared on the market. It is applied by spraying on the wall of the wall, which improves its thermal insulation properties. Polyurethane foam is very light, has excellent operational properties. However, for its application it is necessary for special equipment, which makes it impossible to conduct independent work.

Materials for insulation floor housing with their own hands

If the walls of the house are better to insulate outside, then work with the floor will have to be inside the room. Through the lavety floors, especially on the first floors, up to 25% of heat is lost. Floor insulation is a simpler task in comparison with the walls. For these works, both bulk materials are used and slab insulation.

Among the first can be noted:

- Granulated slag.

- Ceramzit.

- Clay.

Polystyrethillets and basalt mats are most often used from plate insulation.

On top of any insulation necessarily pouring a screed.

Special attention when laying the insulation layer on the floor surface should be given waterproofing. It is placed both under the insulation and on it before the fill of the solution. This is especially true of the base and first floors.

Materials for internal housing insulation do it yourself

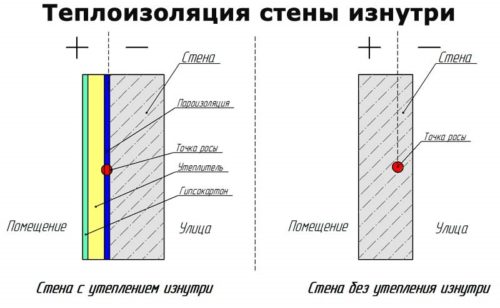

Internal wall insulation is used very rare, as it is associated with a certain set of problems. It is economically justified, it is only for the insulation of apartments on the upper floors of high-rise builders, where without the help of industrial climbers just can not do.

As for the external surfaces of the walls, for internal insulation apply:

- Mineral wool. Especially popular has recently become foil material. The external side has a foil layer, which reflects infrared radiation, without giving it to leave the room limits. The effect of it is not too noticeable, but in the struggle for each degree and it is important. Mounting mineral wool is possible only with simultaneous installation of a frame to which the finish coating will be installed.

- Polystyrene foam. This is the most popular material for installation both outside and indoors. Its installation does not require additional installation of the frame, and ordinary plastering can serve as an finishing coating for it.

- Despite the fact that the material will be used with internal insulation, the installation of a vapor insulating layer is mandatory. To do this, use special membrane material, which makes repair more expensive.

Features of the insulation of country houses and cottages with their own hands

For a country house, it is mandatory for insulation besides the walls and gender are the foundation and roof. If you do not make insulation of the attic room or attic, the lion's share of heat will simply go up. For the insulation of the attic use the same materials as for the insulation of the walls:

- Mineral wool.

- Styrofoam.

- Basalt insulation.

In some cases, a layer of ceraims is poured on the surface of the ceiling from the attic. Such a ceiling will perfectly keep warm.

For foundation, extruded polystyrene foam is mainly used, which is placed after installation and is covered with waterproofing. Bituminous mastic is used as the latter.