The main purpose of the entire modern construction is to reduce not only labor costs, but also energy saving. In this issue, polystyrene bonts is one of the most promising materials, which is actively conquering a good construction.

Content

Composition of polystyrevbetone

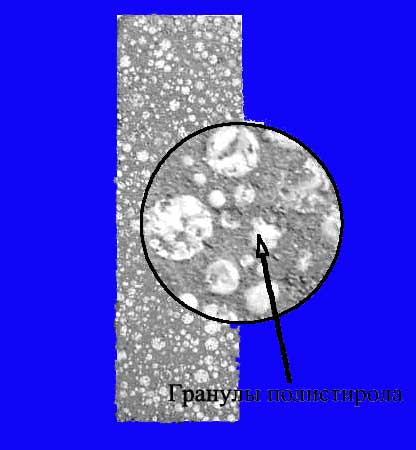

Polystyrevbetone is a lightweight concrete, which has a density of 150-600 kg / m3 and a special cellular homogeneous structure. In this case, it is a heat-insulating composite material consisting of:

- portland cement;

- pellets foamed polystyrene foam;

- slagoportland cement (400 or 500 brands);

- water.

At the same time, in order to give it thixotropy and the necessary plasticity, as well as adjust the time of setting, modifying substances are added to the solution, which ensure the acceleration of the setting and are plasticizing and air-dyeing additives.

Polystyrene manufacture

The strength and mass of the PSB affects the structure of the cement hardened paste, around which particles of aggregate are located having a form of foamed polystyrene.

In order to manufacture a large polystyrene structure, each granule must be coated with a small layer of cement glue, which is an incredible complexity, since the aggregate itself has a round and smooth shape. Therefore, special equipment and chemical impurities are used.

The dosage of the aggregate for expanded polystyrene is set by volume. It is for this reason that it is possible to set the exact pore size and the volumetric mass of the PSB. At the same time, using a special production technology, you can create a polystyrenebetone that will have a closed structure.

Construction of polystyrevbetone

Applying polystyrene bonts in construction have become relatively recently, since this building material has wonderful performance characteristics, allowing it to use it even for plates of overlapping.

In addition to good stiffness and high strength, PSB is much easier than standard concrete and has excellent thermal insulation characteristics. It is used in cases where the building needs to give strength and at the same time reduce the overall weight of the structure. Thanks to the use of this material, installation works are much simplified and the timing of their execution is reduced.

Overlapping from polystyrene bonts

In addition to the building structures, the slab plate from the PSB perform the function of the heat insulator, which is effectively proven during the arrangement of a flat roof. In this case, such a surface provides excellent adhesion with waterproofing rolled materials, which allows you to refuse to use an additional screed.

Polystyrevbetone perfectly tolerates temperature differences, it is frost-resistant, he is not terrible with increased humidity, and due to the huge strength it allows you to withstand large snow loads.

Plate production

PSB plates are available with varying degrees of density and thermal insulation. All the necessary characteristics and properties are reflected in their marking. To give a special strength, the plates are reinforced with special steel frames, which are made of class A III reinforcement. In this case, the diameter of the rod is carefully selected depending on the loads. The bearing capacity of the plates is from 50-500 kg / m3, which allows them to be used in the form of overlaps of most types of rooms. Thickness can be 115-180 mm.

On the basis of polystyrene batter, 3 overlapping systems were created:

- monolithic (on professional flooring);

- half-mounted (bulk layer and mounting plates - from w / b);

- installation (filling items and bearing beams - overlap plates).

You can install plates from PSB at any time of the year manually either with small forklifts. In the process of using roofing plates and flood slabs, plastering is not required, as a result of which the timing of finishing work is reduced.

Polystyrene characteristics:

- is a reflare material;

- used at temperatures from -60 ° C to + 70 ° C;

- installs a comfortable microclimate;

- has a reduced sorption humidity (4-6%);

- the tensile strength is 0.5-2.5 MPa;

- due to increased vapor permeability, air humidity is capable of adjusting;

- is a "breathable" building material;

- has increased frost resistance;

- environmental;

- hygienically safe;

- does not rot;

- is not attractive for rodents;

- has low thermal conductivity;

- durable;

- has excellent noise insulation;

- has a low density;

- remarkably gives warmth;

- does not give a shrinkage;

- durable;

- on the basis of the PSB, you can install any equipment before making a screed.

Monolithic PSB

The monolithic polystyrene is a high-quality building material used for the heat and sound insulation of enclosing structures, roofs, floors and other engineering buildings of various purposes. It is produced with various density marks (D200-D400), which ensures widespread use during the reconstruction and in the construction of buildings.

When building houses, monolithic PSB can be used:

- with the arrangement of a flat roof;

- in the form of a fencing design;

- as a heat and sound insulation layer;

- as the insulation of the walls and plates of the foundation;

- instead of a cement screed;

- in the form of a bulk sex.

Advantages of monolithic PSB:

- has high frost resistance;

- is a labor-burning building material;

- has high thermal insulation and durability;

- moisture resistant;

- has increased strength;

- designs from this material are dry;

- has excellent vapor permeability;

- environmental purity;

- wonderful sanitary and epidemiological indicators, etc.

Monolithic insulation of polystrolbetone

Due to the fact that the polystyrene bontoon has a homogeneous structure, in the case of monolithic insulation, it eliminates the formation of condensate between the layers.

Polystyrevbeton floors

With incredible bending strength, this building material does not ourselves and does not give cracks, which is especially relevant when equipped in the floor building. At the same time, low sorbing indicators allow monolithic PSB to keep their own thermophysical properties even with a wet climate.

Polfolbeton contributes to the formation of perfect rally, which eliminates the occurrence of non-recorded surface sections. In addition, during operation, it can be repaired without problems.

If you wish to apply this building material on your own facility, you can use several options for its production:

- buy dry polls, which is packed in bags;

- separately purchase components for polystyrene bonts.

The advantages of the PSB as insulation:

- with the insulation of the profile of metal increases the rigidity of the roof and protects against corrosion;

- does not require use in the roofing works of thick screeds for the load distribution;

- eliminates the formation of seams between the plates;

- they can pour the roof that is at an angle to 30 °;

- when using the PSB roofing is not deformed, retains hermetic and integrity;

- over time, this material is not compressed;

- is durable;

- use it is economically profitable.

Construction of a polystyrene house

Houses built from PSB have very high heat resistant, which allows saving gas and electricity. When using a large-scale material, the walls of polystyrene foam beetle are becoming resistant to the occurrence of cracks, they are not terrible to send and move the soil.

Blocks that are used in low-rise construction:

- jumpers from PSB;

- plates of overlapping from PSB;

- block-partitions from 10 cm or more;

- wall blocks (30, 35, 37.5 cm or more).

With regard to the reinforcement of bridges PSB, it is designed for laying slabs. Its main task - to create maximum stability of the building, even in places where there is a high seismological activity.

Construction using PSB makes it possible to take into account all the desires of the consumer, starting with the project of the structure and ending with its finish.

Polystyrene wall blocks have an ideal surface, therefore, with the facing of the finished building, virtually any finishing materials can be applied:

- siding;

- block house;

- brick;

- plaster, etc.

Blocks made from this building material are manufactured by various thickness and size, which effectively affects construction work.

In terms of its characteristics, polystyrene foamball is far superior to the nearest competitors - foam concrete and aerated concrete, since with the same sizes of wall blocks, the construction of it will be stronger, warmer and less create a load on the foundation.

Polystyrene production technology video: