Plastic windows today are very popular. These designs are installed in apartments, country houses, in offices and other public areas. Next, we consider in more detail the features of the installation of a plastic window with unpacking and without unpacking with their own hands.

Content

- Installing the plastic window with your own hands. Types of plastic windows

- How to make a measure of plastic windows with your own hands

- Methods for installing a metal-plastic window frame

- Features of the installation of a plastic window into a wooden wall with their own hands

- The order and features of the technology of installing plastic windows with their own hands

- Preparation of the window opening for the installation of a plastic window

- Features of the work on preparing for the installation of plastic windows with their own hands

- Installing a plastic window in a brick wall with your own hands

- Rules for the installation of windowsill plastic windows with their own hands

- Rules for installing sings with their own hands

- Rules for installing slopes for plastic windows with their own hands

- Installing the plastic window with your own hands: Video

Installing the plastic window with your own hands. Types of plastic windows

Before proceeding to the description of the plastic window installation process, let's figure it out with what types of designs exist today in the construction market.

By the number of flaps distinguish the following designs of windows:

- Single. As it is clear from the name, they consist of one sash. Most often, this sash is manufactured opening, as the window should open to ventilation. This is the most economical design of the design that is installed most often in economic buildings and country houses.

- Bivalve. In such structures there are two sash. They can both be relevant either combined (one opening, and the other is deaf). This type of plastic windows is used in apartments, private houses, offices, public premises, etc.

- Three-stranded. Such structures are quite cumbersome, so they are recommended to be installed only in rooms having a large area. Most often, this type of plastic windows is mounted in living rooms, large canteens, etc. In such structures, the average sash remains deaf, and the extreme - open both in the ventilation mode and completely.

Depending on the design and number of chambers, the following types of plastic windows are distinguished:

- single-chamber

- two-chamber

- three-chamber

- four-chamber

- pleight-chamber.

How to make a measure of plastic windows with your own hands

Before ordering a window, you need to find out its exact dimensions. To do this, you need to know the configuration of the window opening. Window openings are:

- With a quarter. The same openings are characteristic of panel and brick multi-storey houses. Make a quarter to minimize heat loss.

- Quarter to. Basically such window openings are inherent in private buildings, including houses from a tree.

Terms and procedures for measuring:

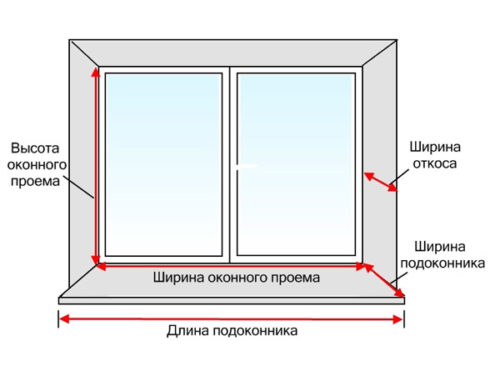

- If a quarter is present on the window opening, then the width and height of the frame is measured in its narrowing place. In this case, it is necessary to add 30 mm to the width indicator, while the height is left according to the results of the measurement.

- If the window opening does not have a quarter, then 30 mm is subtracted from its width to ensure the gaps on each side (15 mm) for the gate. The upper gap should also be at least 15 mm.

- The lower gap for any type of window opening should be at least 35 mm for the installation of the windowsill.

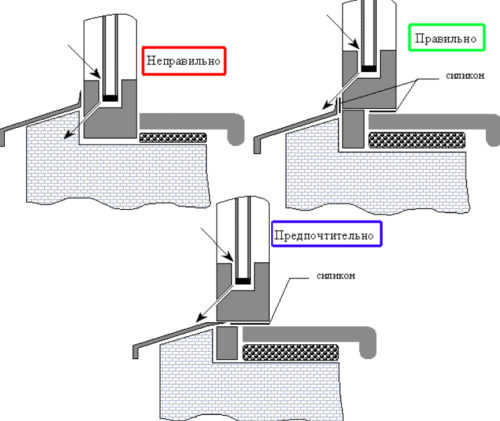

- After calculating the size of the window, the same operation is carried out for the windowsill and low tide. As a rule, the windows are placed in the center of the window opening and deep into 1/3 of its depth. Usually brigades of installers of metal-plastic windows make it possible. However, if you install it with your own hands, you can do anything. If the window opening has a quarter, then the window is usually placed close to it with a gap for gate, if not, the installation depth can be adjusted independently.

- From how deeply the frame will be located, the width of the windowsill and low tide depends. These parts have standard dimensions, so that the frame is mounted in such a way that it goes under the standard windowsill and low width. It is still worth remembering that the windowsill must half over the edges of the radiator located under it.

- The length of the windowsill and the popular should be 50 mm more than the width of the window.

Having done all the necessary measurements, you can go to the manufacturer to order a metal-plastic window.

Methods for installing a metal-plastic window frame

Methods for fastening the metal-plastic window frame do not depend on the number of cameras in the profile, as well as from the thickness of the glass package. A greater influence on the choice of the installation method has the material of the manufacture of walls, as well as the configuration of the window itself.

The main mounting materials for installation of windows do it yourself:

- Anchor bolts. The holes for their installation are drilled through the profile into the wall. This method of installation is considered the most stronger. That is why it is used when installing heavy structures with several opening flaps. However, it is suitable only for concrete and brick walls. Anchor work very well on the "cut". That is why the window is not afraid of blows, which are experiencing a design when closing a heavy sash.

- Anchor plates. They are perforated steel plates that are screwed along the outer perimeter of the frame and to the wall of the opening. Usually this method is used when installing a window in wooden houses. Thanks to the larger fastening area, the tree has a smaller load, which has a positive effect on its durability. Even on the anchor plates put lightly deaf structures.

Some masters combine both methods using and anchor plates and anchor bolts.

Features of the installation of a plastic window into a wooden wall with their own hands

Tree is a very common material for the construction of houses. Installing windows in a log house or bar has its own characteristics that must be taken into account that the window serve longer:

- The installation of metal-plastic windows is better to start in a year or two after the end of construction work. This period is necessary in order for the walls to give the maximum shrinkage.

- Installation of metal-plastic windows in a wooden house is never carried out directly in the opening. First, a wooden frame is installed in it, to which the window is fixed.

- It is necessary to take into account the fact that the shrinkage of the walls can continue and after installing the window. To avoid the skeleton of the frame, a technological gap is left to a thickness of 50-70 mm. It is filled with a Jute insulation, which will play the role of the shock absorber. In the event of a shrinkage of the walls, it will allow you to leave the frame in the initial position.

- When using a mounting foam as a compactor, a foil polyethylene gasket is installed around the perimeter. It is necessary so that the moisture from the tree is not transmitted to the foam.

The order and features of the technology of installing plastic windows with their own hands

Preparation of the window opening for the installation of a plastic window

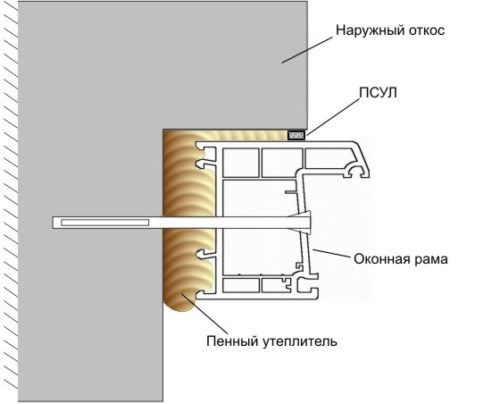

The preparation of the outlook itself is to remove the remains of plaster, the old frame, fastener, insulation. On the walls of the opening should not be dust. It is desirable to handle the window opening of the primer for better adhesion of the mounting foam and surface.

Features of the work on preparing for the installation of plastic windows with their own hands

Manufacturers tend to supply a window assembly. So easier to transport it to the customer.

- In order to carry it out, it is necessary to remove the flap and the glass from the frame. The sash is separated from the frame as follows: first from the top loop, the pin is pulled out. After that, the sash is removed from the bottom loop, slightly raising it. The double-glazed windows are removed, after removing the stalls. First remove longitudinal staps, then transverse. To do this, use a spatula or reverse side of the knife.

- The shot glass is mounted to the wall below the tilt. In no case cannot be laid it on the floor. Even a small blockage can cause cracks.

- Next, from the outside of the frame, it is necessary to remove the protective film. After installation, this will be very problematic.

- The next step is to mark up the installation of anchor bolts. The distance from the edge of the window to the first hole should be no more than 150 mm. Anchor installation step - no more than 700 mm. The drilling holes for the anchor bolts are carried out with the outer side of the frame. Anchor plates are attached to the outer side of the frame using self-samples with the holding of the same distances that when installing anchor bolts.

Installing a plastic window in a brick wall with your own hands

When the preparation of the window and the opening is completed, you can start the installation of the frame:

- To ensure the technological gap uses wedges of wood or special plastic corners.

- Next, with the help of wedges, the frame is set by level. The verticality of the racks of the frame is checked, as well as the horizontal of the base and the crossbar.

- The next step in the wall through the holes in the frame is drilled by holes in the opening in which anchor bolts are inserted. After that, again check the position of the frame level, and then tighten the anchor.

- Next on the frame there are previously removed parts - sash and glass, after which all technological gaps are mounted with mounting foam. After that, the gaps are closed by a protective film.

Rules for the installation of windowsill plastic windows with their own hands

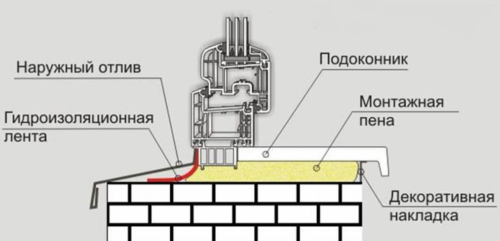

The next step is placed plastic window sill. Make it is quite simple. Slices of bars are stacked on a part of the wall under the window so that the windowsill was put up by level. After that, the gap is blown down by mounting foam. For a day to the surface of the window sill, you must put a small cargo (2-3 bottles with water). Do this in order for the windowsill not rose with the polymerization of foam.

Rules for installing sings with their own hands

Films are installed last. As a rule, they are made of galvanized steel, which makes it easy to cut the material under the size of the window opening. After the lifting width is adjusted, it is installed close to the window and fixed with self-draws. Then the lower gap is fixed by foam.

Rules for installing slopes for plastic windows with their own hands

For the facing of slopes, it is best to choose such a material like plastic. Such slopes have many advantages:

- Suitable for any room design. They are universal.

- They can be easily dismantled and replaced if necessary.

- There are many design options and plastic color solutions designed to clamp slopes.

- Plastic is not afraid of a high level of moisture, and also provides good sound insulation.

- A layer of insulation can be placed in a niche between the window opening and plastic panel.

In order to set the slopes on the plastic windows, the following set of tools will be required:

- Roulette for measurements.

- Silicone layer.

- Dowel-nails, construction brackets, self-tapping screws.

- Knife.

- Screwdriver.

- Perforator.

The procedure for performing the installation of slopes on plastic windows:

- Initially, you should attach the frame from the rails. Rake to each other are attached with the help of self-tapping screws. In order for the frame to be placed strictly vertically, check the accuracy of the work with the help level. It is desirable that the framework is durable and stable. Then the operational life of slopes in the finished form may increase several times.

- Plastic panels should be installed on this frame. Initially the starting rail is attached, which is fixed on both sides by self-draws. Further strips are connected to each other by the technology of "spike - groove". On each panel of plastic there is a special groove in the side, in which the groove of the next plank is started. At the same time, make sure that the planks are lossed tightly to the installed frame.

- Next, with the help of a construction stapler, a decorative F-shaped plank is attached. She is fixed for one of two ribs. This will be the final step of the installation of slopes on plastic windows.

http: //prodarm46.rf