Anyone who began to build their own dwellings, first of all asked the issue of the foundation. The correctly mounted base for the house will last long, if everything is done correctly and adhere to the necessary technologies. To make a solid foundation, without spending huge tools, it is necessary to correctly select the type of formwork and the installation method. Well-performed formwork will allow to achieve the highest rates of the strength of the foundation and walls. The issue of home the foundation for the house is quite serious because it requires compliance with all building technologies. In addition, it can be a penny. To save on the workforce, without losing the quality of the design, the installation of the formwork can be made with your own hands.

Content

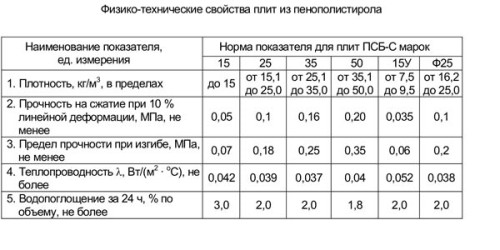

Characteristics of non-removable polystyrene formwork

Polyeneets began to use in construction not so long ago, but he has proven itself very well in the modern market. This material is widely used, the main task of which is insulation of the room. The formwork made of such a material lasts for a long time, since in addition to the reliable fixation of concrete, it also carries insulating properties. No wonder most Western and European countries are inclined to choose from polystyrene foam formwork for their future dwelling. It serves as one of the most important elements necessary for the construction of the carrying and coasting structures of various purposes.

General

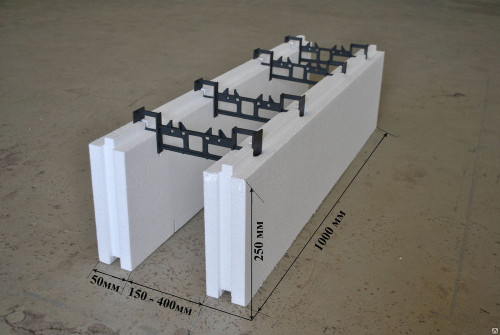

In order to mount formwork, use special blocks. Of these, the fences carrying the walls and the foundation of the future room are built. The formwork made with the use of such material is customary to belong to the beaming type, since it remains with the foundation after the fill with concrete. The house built using the non-replaceable formwork from expanded polystyrene will become a reliable housing due to the high indicators of the strength of the base. In addition, in such a formwork you can pave electrocommunication without fear that moisture will get there.

The formwork is made on plants under the order according to individual sizes. Measurement of the foundation or walls is better to entrust the company in which you will order formwork. In some manufacturers companies, blocks have different wall thickness and sizes, so it is better to trust a professional in this matter. In the disassembled form of the formwork resembles a huge children's designer, but note that the personnel assembling of polystyrene foaming is far from a children's occupation, but an important building process. Incorrect sequence of action during installation can spoil the foundation of the room. In this case, there will have to give considerable means for restoring the design.

Advantages of non-removable polystyrene formwork

To better understand the characteristic features of the polystyrene foam formwork, it is important to estimate all the main qualities of this material.

The main advantages of the formwork made of polystyrene foam include the following:

- high installation speed (this formwork refers to the unavailable form, which allows you to save time on the dismantling of the frame);

- easy installation (this material is easy to handle and mount);

- multifunctionality (In addition to holding the solution, polystyrene foam plates perform an excellent function that allows heat to hold indoors. In addition, such a formwork is perfectly coping with noise insulation of the building);

- easiness (extruded polystyrene foam is quite easy, moreover, durable material. The formwork does not create additional loads on the foundation);

- thermal insulation (in addition to the arrangement of foundations and walls, this material is used when mounting a warm floor and insulation of facades);

- moisture protection (excellent moisture-resistant properties do not allow the material to absorb or skip steam. It serves as a kind of hydrobarier);

- low price (if your choice fell on this type of formwork, then you can significantly save. This material is quite inexpensive and technological. In addition, the polystyrene foam formwork is quickly mounted, and you will not have to pay extra charges for unnecessary business days for unnecessary teams) .

We hope to consider all the advantages of this material, you stop your choice on it. But do not forget that any building material always has its drawbacks, although not a few.

Disadvantages of non-removable polystyrene foaming formwork

Getting Started formwork, it is important to put all accents correctly. Referring all the shortcomings of this material at the initial stage, you will achieve the best results.

The polystyrene foam formwork has the following disadvantages:

- low environmental performance (polystyrene foam under the influence of high temperatures is distinguished by poisonous substances);

- installation of formwork from this material is permissible only in the warm season;

- plastic struts are used to arrange walls and foundations. Some manufacturers are saved on the production of plastic elements, which directly affects their strength;

- the ability to use a crushed stone as a fraction with a fraction of no more than 16 mm, which slightly narrows the circle of using the formwork of this type;

- the maximum allowable level of fill is 1 meter, so it is better to perform work manually, without using concrete pump. Excessive amount of solution can disrupt the integrity of the formwork;

- at the walls of the polystyrene foam formwork, very low air paint records. This property forces forced ventilation indoors;

- the use of deep vibrators should be excluded. The use of this tool adversely affects the strength of the structure;

- since fittings are used in the formwork, it is necessary to ground the contour of the structure. This will help protect it from the atmospheric discharge.

The disadvantages of such a formwork are fully expected, however, such advantages as the speed and simplicity of installation, as well as high thermal insulation qualities, allow this formwork to be attributed to popular methods for arranging the foundation.

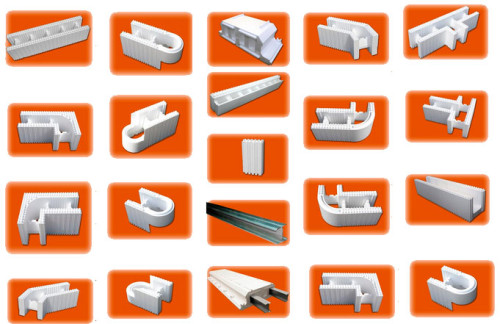

Constructive parts of the formwork

As mentioned above, for the arrangement of the non-coordinate formwork from polystyrene foam, the blocks that are manufactured under the order at the factories are used. In each case, they have different sizes and shapes. In addition, blocks can be manufactured using various techniques and materials.

To make one or another block, the original production method is used at the factories. For this, with the help of a special, heated metal string, from a large cube of polystyrene cuts the necessary elements. Often this method is computerized, which allows to achieve accurate results, without losing the quality of the future product.

Component elements of polystyrene foam formwork include:

- decks (used in the arrangement of foundation blocks, as well as wall, rotary, driving and ordinary parts of the formwork);

- corner and connecting elements;

- face plugs.

Assembling formwork from polystyrene foam slabs does not provide for the use of heavy construction equipment. Since the components of the formwork have a small weight, then everything can be performed by itself. The formwork is collected according to the principle of the constructor, using the fastening groove method. Often for the additional strength of the attachment use a thin layer of solution (1-3 mm).

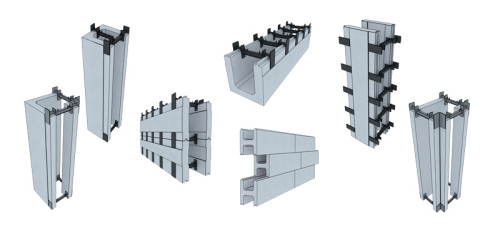

Method of layout formwork

The assembly and installation of polystyrene foam formwork involves the use of two methods for mounting plates and other components. Using one or another method, you will get an excellent result. What features and conditions are necessary for each method? To select the formwork of the desired type, it is necessary to carefully examine the characteristic features of each method of location.

Applying the non-replaceable formwork from polystyrene foam in the arrangement of the foundation or housing walls, the following methods of arrangement of components are used:

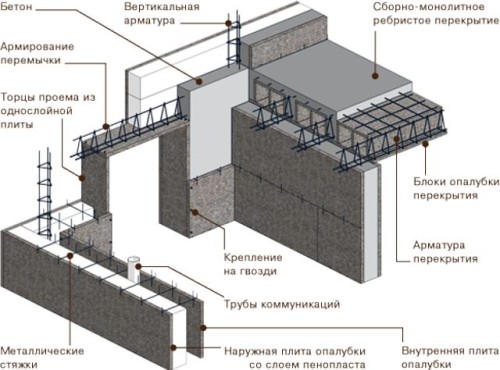

- Heatel outside. The formwork is made up of hollow blocks, which are parallel to underlying polystyrene foam sheets, connected by plastic or metal jumpers. With the help of these blocks, the wall or foundation is stood in stages, thereby forming the basis of the future design. To give additional strength, fittings are installed in the blocks, after which the concrete solution is beginning.

When mounting the formwork, this method is also used by the Blochetter method. The role of the framework is performed by the rebreak, which fastened polystyrene foam plates with special polymer plugs. Plates have a sufficiently high density and strength, besides, they perform the heat-insulating function outside the base. For formwork, the ceiling parts use elongated polystyrene foam panels. Through the plates along the holes are located. Additionally, the ceiling overlap is reinforced with metal guides, which are embedded in a sheet of expanded polystyrene.

- Heater inside. This method provides for the use of panels with a thickness of 1 to 25 cm. They are covered with a steel reinforcing mesh, after which the special concrete solution is applied on both sides. This is done in 2-3 layers, splashing concrete under pressure. The polystyrene foam sheets used in such a formwork design are often called sandwich panels. Such a way is much cheaper than block-sheath, because it does not require additional finishes. Due to the reduction of the consumption of concrete associated with the small thickness of the walls, this design is significantly economical than the above, moreover, it has higher frost resistance.

Installation of non-removable polystyrene formwork

Installation of non-replaceable formwork from extruded polystyrene foam is quite simple. But, like any type of work, implies the use of special technologies. To avoid difficulties and errors associated with the arrangement of the walls and the foundation of your home, it is better to adhere to the correct sequence.

Assembly and installation of non-replaceable polystyrene formwork

Starting the foundation work, using polystyrene foam coating, it is important to adhere to the correct algorithm. If you do everything clearly and in order, then the quality of work will be at the height, and the result of your efforts will serve not one dozen years.

To collectively assemble and install polystyrene formwork, you need to follow the next algorithm:

- Make a plan of a future design. Prepare all tools and materials.

- Align the plot. Use a shovel and shoulder. In the case when the surface has a complex coating, use the planning technique.

- With the help of metal wedges and threads, mark the territory of the future foundation. Do not forget to observe the parallelism of the lines and the sharpness of the corners. Use a construction kit and level.

- Drop the trench for future foundation. The depth of the trench varies depending on the size of the future building. Make all work at this stage extremely accurately. Do not forget that you will be mounted a unknown formwork, therefore it will not be possible to plan the surface of the walls subsequently.

- Check the surface plane, and if everything is smooth, start to equip the drain pillow. To do this, use a mixture of sand and rubble with a layer of 15 cm, which is subsequently equal to the trambl. It will allow the load evenly distribute.

- In the pillow, install pieces of fittings required for further ligament of formwork elements.

- Fill the pillow with a thin layer of concrete to achieve the maximum evenness of the future base. Such a "sole" will serve as an additional enhancement of the foundation and protect it from shifts.

- When the solution was frozen, begin to sequentially install the structural components of the polystyrene foam formwork. Blocks are installed, putting on reinforcing rods. It is important to have a clear line. So that the formwork does not move, make blocks clearly by grooves. To enhance fastening in the corners, use special connecting and fixing blocks.

- If there are gaps in the connections between blocks, they are better immediately sealed.

- Control the plane of each row. The walls must be clearly parallel, the vertical is observed, and the rounded elements must be "twisted" under a given radius.

- Check all connections for the presence of binding formwork elements.

- Now you can start pouring concrete. Do it gradually in small layers. Do not forget that when using a concrete pump, the formwork can simply deform.

- When the last layer is flooded, align the fresh concrete with the help of a trowel.

Performing all the works described above, do not forget about safety technician. Completely follow all the instructions, then work will become pleasure, and the result will not make it wait.

Advice

To perform work properly, quickly and efficiently, to the same, avoid the undesirable consequences and repairs of the foundation, it is better to immediately pay attention to all nuances of editing.

When installing polystyrene foam formwork, pay attention to the following points:

- do not buy blocks in advance. Polystyrene foam, if it is in air for a long time, begins to slowly collapse, which can adversely affect the strength of the formwork. It is better to purchase a formwork design immediately before work;

- when you work at the stage of pouring concrete, consider that jumpers connecting polystyrene foam sheets make it difficult to spread the solution. It is better to move around the entire perimeter of the construction;

- do not use such a formwork near the elements operating at high temperature modes;

- do not choose the cheapest "constructor" formwork. Composite elements may be bad for grooves, and the material does not fully fulfill their function. It is better to stay on the middle version;

- always seal inter-block seams. Use for this construction assembly foam;

- although polystyrene foam and protects the foundation from moisture, it is better not to use such a formwork in the arrangement on a wet soil.

To clearly figure out the issue of building the foundation, using non-replaceable polystyrene formwork, we advise you to see the following video:

As you can see, the installation of such a formwork is practically no different from others. Only materials and some features of the installation are changing. It is important to always adhere to the correct sequence, and then work will not seem so difficult to you, and the quality will be at the highest level.