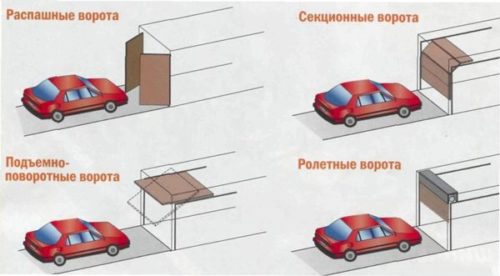

When building a garage in a private house, each of the owners is facing the choice of types of gates. Among domestic car enthusiasts, swing metal gates are considered the most popular. However, the problem of such a design is that it should be enough space for their opening on the site. Yes, and automate the process of opening and closing the flaps is almost unrealistic.

Content

Another thing is a sectional gate. They were invented relatively recently - in the second half of the last century. And during this short period of time they won sufficient popularity. In Europe and the United States, almost all garages are equipped with such a gate, since their use is very convenient. They occupy a little space, do not automate without problems, they keep warm well. About how to install sectional doors with your own hands - further in the article.

Design and principle of sectional garage gates

The principle of operation and characteristics of the sectional gates is quite simple:

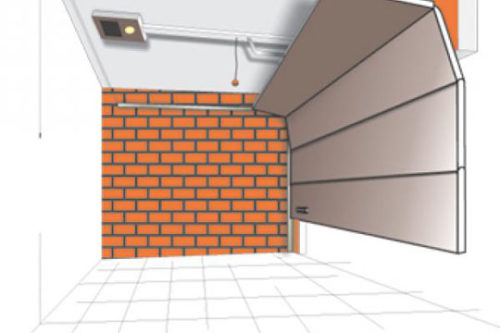

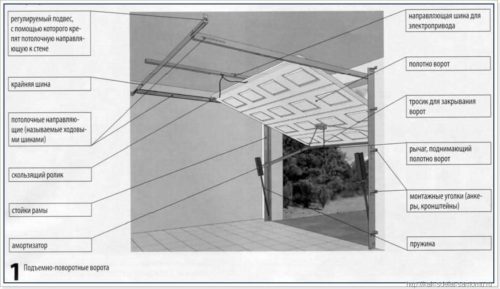

- The canvas, which consists of several sections, moves along the guides installed on the frame and under the ceiling, and then removes up. Due to the fact that the gate canvas is not solid, but consists of several sections, it is easily removed under the ceiling. Sections are connected with each other with hinge loops.

- Standard sectional doors have 6-7 sections. They represent a sandwich panel. From the outside, it is made of aluminum or galvanized steel, and with internal - can be made of plastic or steel.

- The inner part of the panel is filled with moisture-resistant insulation, such as polyurethane foam. It not only takes care of the preservation of heat, but also carries a sound insulation function. "Walk" panels thanks to the rollers, which are installed in the side ends of each of them.

- For heated garages, the thickness of one panel should be 35-45 mm. The thermal insulation properties of such sections are comparable to 1.5 brick masonry. For cold garages - enough thickness of 20 mm. Metal thickness for sectional gates 1.5 - 2 mm.

- At the ends of the panel, a cork or rubber seal is installed. With closed gates, it fills the space between the panels, preventing the appearance of cold bridges.

- When installing sections, the maximum clearance value between them is accepted at 4 mm.

- An elastic material is installed on the end of the lower section, due to which the steel section does not face the floor in winter.

- The drive of the sectional gate is attached to the ceiling. It may be mechanical or electric. The latter is preferred since thanks to it you can make an automated system.

Standard overall dimensions of sectional garage doors, which are most often installed in the garages:

- The height of the opening is up to 6 meters.

- Width of opening up to 7 meters.

- The width of each panel is not more than 0.7 m.

Naturally, under the order you can make the gate of any size, however, it is worth remembering that the greater the harder design, the greater the likelihood of its breakdown or jamming. If the gate is embedded, there is a high probability of failover the drive engine.

Advantages and disadvantages of sectional garage gates

Compared with all-metal swollen gates, sectional has a large number of advantages:

- They save space in the garage and in the yard. To open a swing gate, a large amount of free space is necessary. Disintegration doors can not be discovered if the car is parked close to them.

- Excellent performance: thermal insulation of sectional garage gates and their noise isolation. Thanks to the application of the technology of sandwich panels, sectional doors greatly hold heat and do not let the sound. In addition, despite the fact that they are not solid, and consist of separate sections, they provide excellent waterproofing.

- Versatility. Sectional doors can be installed with the same efficiency on the opening of any width.

- Fire construction. In the production of panels for sectional gates, only materials that do not support burning is used, which is very important for the localization of fire, and the garage is a potentially fire-hazard place.

- Beautiful appearance.

- Long service life and simplicity of repair. If you adhere to the recommendations for the operation of the garage gate, then the service life will be quite long. So, the correctly installed sectional doors can stop several dozen years, and most often the repair of them comes down to replacing one or more panels.

- Ability to automate. If the massive steel gate is almost impossible to equip the automatic opening system, then more than half of the sectional doors are equipped with automation. They can open and close when you press the button on the keychain or react to the signal set in the car tracker.

There are practically no shortcomings of the sectional gate, the only one is the price. It is much higher than that of the usual, due to the greater processability of the product. However, ease of use with interest compensate for additional costs.

Installing sectional gates for the garage with your own hands

Basic moments

As a rule, specialized companies are engaged in the manufacture of details for installation of sectional doors. The manufacture of sections and guides at home is difficult to perform the task. Typically, such products are not durable due to the fact that it is very difficult to fit the guides with an accuracy of a millimeter so that the sections do not enhance, without special equipment is very difficult. But the installation of this mechanism can be carried out on its own, thereby saving a substantial amount of funds.

Some owners prefer to buy individual details of the system, which were already in operation, which reduces the cost of work. However, it is very risky, as it can cause the unbalance of the entire system. It is best to buy a ready-made kit from one manufacturer. Then the installation process will be easier.

Set of sectional gates consists of:

- Sandwich panels.

- Guides.

- Torsion. This device helps return the gate canvas at its original position.

- The opening mechanisms of the garage doors.

Tools for the construction of sectional doors:

- A set of keys.

- Perforator, drill with drill set, including concrete drilling.

- Pistol for setting rivets.

- Hammer, screwdriver set, stationery knife.

- Roulette, square, pencil.

- Individual protection means.

Phased order of work

Order of preparatory work:

- Before starting the installation, a complex of preparatory work should be performed. The installation of the sectional gates is possible only on the smooth surfaces of the tensile and the perts, which must be in the same plane.

- Next, the height and width of the opening are carried out. It is done at three points. For the work is made the most important thing.

- The length of the canvas, and, accordingly, the number of panels is determined depending on the height of the opening with a reserve of 500 mm for the mechanical gate and 1000 mm for a gate with an electrically driven. Depending on these parameters, the set of the gate is ordered.

Basic rules for installing sectional gates:

- The main rule during installation of the sectional gate is the exact observance of the verticalness of the opening and reliable fastening of all elements of the system. Even millimeter threads are unacceptable.

- The size and type of fastener, which is used for installation, must comply with the manufacturer's recommendations, if it has not been supplied complete.

- For alignment of the guides, the use of mounting foam or wooden wedges, steel gaskets - without compromise, is unacceptable.

The order of installation of sectional gates:

- The installation process necessarily begins with the alignment of the floor, perts and tensile. They must be located strictly in terms of level and in the same plane. Places where the gate frame will be installed, you need to stack.

- After the opening is aligned, it is necessary to apply the installation circuits on it, which includes the places of fastening profiles and guides.

- Next, you can proceed to the installation of the box, which consists of guides and nickname. Before this, the fastening for the spring is mounted in the guide. The mounting bolts can not be very tightened, otherwise the gate will be very difficult to open. Guides are connected by a ostel, which will prevent the penetration of dust and moisture inside the garage.

- In order to install the guides in the installation process, the spacer schedule is installed at the bottom. Mounting the gate frame must be reliably, since it will have the greatest load.

- Next, the installation of the upper guides and the dimensional strip begins. Guides are attached to the ceiling with the help of upper suspensions.

- Now you can proceed to the installation of panels. The first panel is mounted on which the rubber seal is put on. The panel is installed in the box and is screwed to the rollers of the guides.

- After mounting the first panel, the rest are installed. They are bonded with each other with hinge loops. After the cloth is mounted, it is raised to a height of 1 - 1.5 m in order for them to enter the horizontal portion of the guides under the ceiling. If they entered without distortion, guides are securely attached to the ceiling. If not, corrective actions are carried out until the canvas move the devices.

- The last stroke is set torsion springs and cables that provide closing and opening the gate. The gate to the garage for two machines is installed on a similar technology.