The private pool on the countryside is a great place for summer holidays of all family members (especially in hot weather). The best alternative to the classic stationary construction from concrete is a polypropylene seamless pool.

Content

Basins varieties

There are 3 main types of pools:

- inflatable;

- collapsible;

- stationary.

Inflatable designs

Such pools occupy a small space. If there is a small summer cottage, the inflatable design is the most optimal option.

Advantages of inflatable pools:

- the possibility of installation anywhere in the country area;

- easy transportation (in case of installation of a picnic capacity).

Some models can be enhanced using aluminum pipe frames.

Prefabricated pools

In most cases, these designs are seasonal products. In the spring they are collected, and in the fall - disassemble. Prefabricated tanks do not have a sand filter. For this reason, from the bottom of the pool, you must regularly remove trash.

Prefabricated containers have small sizes. This is explained by the fact that for assembling the frame, you need to make maximum effort and time.

Stationary containers

These designs have the maximum dimensions. Naturally, stationary pools require the installation of various communication lines, water supply and water purification systems. What will increase the cost of installation work.

To prevent herbs, leaves and other garbage, the stationary design is recommended to cover the canopy or sliding roof.

A distinctive positive feature of inpatient pools is a long operating period. Such structures include polypropylene pool.

Characteristics of polypropylene pools

For the manufacture of the pool, a sheet polypropylene is used, having a different thickness:

- 5 mm - for the walls of the structure;

- 10 mm - for steps and bottom.

This material has the following mechanical properties:

- density - 0.85-0.95 g / cm³;

- stretching with tension - 900-950 mR;

- elasticity at bending - 800-850 mR;

- bending resistance - 25-30 mra.

The unique quality of polypropylene sheet for the pool is the possibility of cutting and processing on machines. From it there is a bowl that can be different in size and form. For the manufacture of polypropylene bowl, polyfusion thermal welding is used.

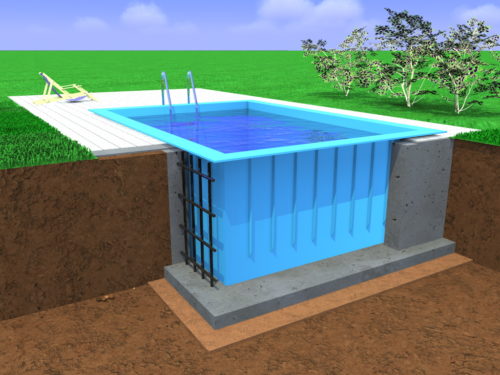

Mounting technology of the polypropylene basin does not provide for the use of formwork. Its installation occurs directly to the concrete site.

In addition to the above qualities, the benefits of the polypropylene basin include:

- environmental friendliness;

- long service life;

- absolute tightness (such additional elements, like illumination, nozzles, skimmer, hydromassage are also made from polypropylene);

- low thermal conductivity (due to this, water cools slowly);

- resistance to the negative effects of ultraviolet rays and temperature fluctuations;

- harmonious combination with any architectural style of the house or surrounding landscape;

- the probability of installation of the design is not only on the street (a sauna, sauna or ground floor of a residential building) is quite suitable;

- undoubtedly carry out the finishing of the inner surface of the structure;

- easy to care (for cleaning the walls and the bottom, a brush with a small handle is used, which connects to the skipping hose);

- the ability to build the pool at the place of its installation (when it does not take place in the entire room).

Polypropylene pool It is better to equip the cleaning and filtering system. Due to this, water can not be changed within 4-5 years. The use of special preparations will not allow:

- algae growth;

- the appearance of dirt on the edges of the bowl.

Features of the acquisition of the polypropylene basin

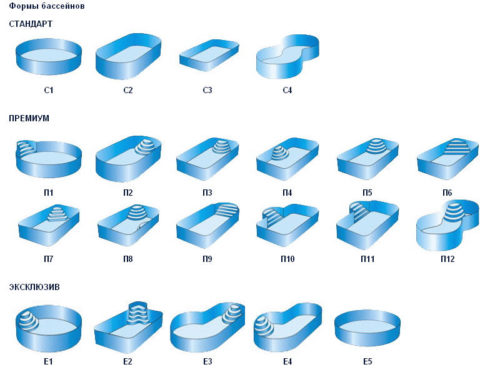

Now let's talk about how to choose a polypropylene pool. The main criteria for purchase are the size and form of construction.

Depending on the volume, a polypropylene bowl of any size can be ordered. The only nuance is that the cost of the standard size basin will cost much cheaper than the production of the container of non-standard size.

As for the form of a polypropylene basin, it can be completely different (rectangular, oval, round, with non-standard configuration). It all depends on personal preferences.

It is believed that the standard are a bowl of 4-6 m long, 2-3 m wide, a depth of 1.2-1.5 m. If a round pool is purchased, then its diameter is in the range of 2.5-4 m.

One of the features of buying a polypropylene basin is the choice of a frost-resistant design. Such a bowl will not deteriorate with a sharp decrease in temperature. And if the pool is heated and cover the transparent roof of polycarbonate, then in the winter, with a small frost, you can safely take the ball procedures.

Installation of the polypropylene basin

Preparatory stages are carried out design and marking work. Everything must be taken into account:

- precise size of the bowl;

- the number of elements and locations of polypropylene sheets;

- the presence of additional equipment;

- distance to tap line;

- remoteness from trees and shrubs (leaves should not get into the pool).

The process of installing the polypropylene pool itself consists of the following steps:

- digging a pit;

- making bowls;

- fixation of design;

- decorative design.

Digger Kotlovana

At this stage:

- on the markup rush peasses;

- rope is tensioning between them;

- pit rushing;

- the bottom of the pit is leveled and is covered with geotextiles;

- the geotextile is embanked by gravel (thickness up to 30 cm);

- the bottom of the pit is reinforced and concreted;

- concrete is frozen;

- in the concrete surface is laid insulation.

The thickness of the concrete base is 0.2-0.5 m. Its width exceeds the size of the bowl by 0.4-0.5 m.

Manufacture of bowls

This process is the most difficult. It consists of such consistent actions:

- polypropylene sheets are unfolded separately according to components (walls, bottom, steps, side);

- the basin bottom assembly is made (extruder welding is carried out from the outside of the bowl);

- the bottom from the polypropylene is placed on a concrete basis;

- for similar technology, wall structures, staircase and sides are connected.

Stairs stairs are welded to the wall and the bottom. Bursts are stacked on the top of the wall and weld. The bowl is necessarily equipped with rigid ribs that are welded to the outside of the structure at a distance of 0.5-0.6 m from each other.

At this stage, the pool elements are also connected (electrical wiring, hydraulic system, pump, filters, backlight, pipes for draining and water supply) to communication lines.

Fixing design

At this stage, the space between the walls of the pit and the pool should be equipped correctly. Stages of work:

- inside the tank, the struts made of wood are mounted;

- all communications are isolated and placed in protective tubes;

- around the bowl is created and reinforced formwork;

- concrete solution is done;

- the mixture is poured between the wall of the pit and the polypropylene design;

- there is a grasp of the solution;

- deleted formwork and struts.

The concreting procedure is carried out in stages. The thickness of the same layer should not exceed 0.3 m. After which, only a day is started to work. Pouring is carried out until the space is fully filling between the walls of the pool and the pit.

If there is an opportunity, then when concreting, the bowl is better filled with water. This is done at the level of flooded layers (at a height of up to 30-35 cm with a gradual increase in water level). The use of this technology will not allow the flavors of the bowl.

Decorative decoration

At the final stage, the pool itself is decorated and the plot adjacent to it. To decorate the bowl, a film from polyvinyl chloride is applied:

- on the walls, the bottom and sides are filmed;

- with the help of mounting glue, it is fixed to the surface of the pool;

- the seams and the extreme part of the film are covered with silicone sealant.

The plot near the bowl is facing the paving slabs.

Video on the installation of the polypropylene pool:

http://drbass.ru/ - Moscow Pool Plant