The houses from the bar have become quite popular in recent years due to its environmental friendliness and good operational qualities. On the characteristics and methods of building such buildings, we will also describe later in the article.

Content

Characteristics of the house from the profiled timber

The advantages of the profiled timber, first of all, should be attributed to the following:

- Relatively low cost and resistance to deformations.

- It is also important that such a house is quite easily erected. This largely contributes to the form of the timber itself. To customize to each other, they are practically not necessary.

- The compounds are turned out to be dense that there is practically no moisture between them, and therefore there is no medium to form a focus of rotting.

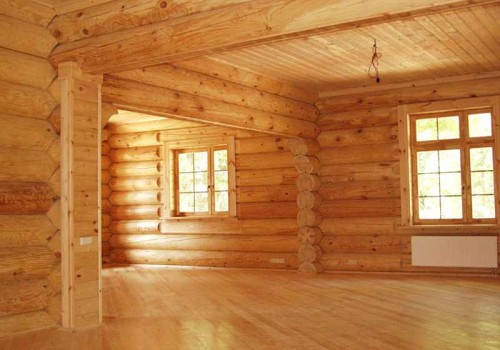

- Walls made of profiled timber have good characteristics. At the same time, both inside and outside they turn out quite smooth. Therefore, in some cases, they do not even need additional trim.

- Shrinkage will be in any case, as in the construction of another new building, however, after it, the house from the profiled bar does not need to be caught to close the gaps - they will simply be not.

- Dense connections of parts of the bar provide protection against the penetration of cold wind, and the house itself is obtained sufficiently heat-insulated in order for it to be comfortable to live by residents.

As for the shortcomings, it is primarily worth noting the following:

- The timing used is undergoing the negative impact of weather conditions.

- In addition, to increase fire resistance, it is required to be impregnated with special means. In addition, due to the humidity, cracks are formed during the drying of the bar. For this reason, it is recommended to choose the material that has passed the chamber drying.

- It should also be said that walls that are not suitable for use in the winter period are obtained from the profiled timber. Therefore, it is required to make additional insulation outside.

- When the house is built, redevelopment or add-on work will not be done.

The construction of such a house begins with a selection of a bar. After all, many operational characteristics of the future structure depend on it. It is worth saying that the price of the house from the bar is relatively low. This is achieved due to the relatively small cost of the timber itself.

The material planned to be applied during the construction of the house must be quite high quality. In general, pretty strict requirements are presented to wooden structures. The walls of the wooden house should be durable and at the same time to last long enough. In addition, they must have sufficient sound insulation. It is also important that the walls of the building are maintained inside the normal temperature. In general, any wood without special processing is poorly opposed to fire, and, therefore, fires. In addition, the disadvantage of such a material is that during the first few years shrinkage occurs.

A spruce, pine and other conifer breeds are most often used to build a house from the bar. This is due to the fact that the arrays of these trees are best suited for sanitary and hygienic requirements. In addition, coniferous breeds have great resistance to rotting, compared with other wood. In particular, this is possible due to the fact that the cracks on them appear much less often.

In general, today produce two types of timber - it is profile and solid. Each of them has its pros and cons that even consider it below. Profile is called so because Brusa give a certain profile. Options of the appearance are only two - with spikes and veneer grooves. Both types of compound are made in the entire length of the bar.

The advantages of the house from a single timber, first of all, should include a fairly low cost. The one-piece timber as the material is quite common, so its purchase should have no problems. Due to the simplicity and speed of production, the finished material even under the order can be obtained quickly enough. The undoubted advantage of solid timber houses is the fact that the construction does not require special equipment. However, the additional costs required to finish, which is one of the drawbacks. In particular, it is necessary to invest in siding or battens. Sam timber material must be of high quality, which should be considered at the stage of selection. For example, if the material is deformed, the wall will turn out uneven. In addition, between the bars in site design are formed, where moisture can penetrate, and as a result developed the fungus. In this case, even the timber material is not initially dry. To avoid the development of fungus due to humidity, timber can be treated with an antiseptic, to which again requires money and time. The disadvantage is also the fact that between the rims to create a strong produvaemost, which negatively affects the conservation of heat in the house. Yet we must not forget about shrinkage and shrinkage, due to which cracks can occur in the material. Because of what is necessary to sheathe the walls on both sides.

Construction of timber houses

Laying the foundations and floor

Construction of timber houses turnkey start with the foundation and the sill. The base can be used as pile foundation or melkozaglublennuyu tape. It will be quite cost-effective solution. Before you choose one or the other option, it is necessary to calculate the load of above-ground parts of buildings, taking into account the nature of the soil-ground on the site. It is on the basis of this choice is made in favor of one or another type of foundation. In addition, you need to calculate approximately how much it will weigh the finished house. These calculations are usually based on the knowledge of the number of cubic meters of sawn timber, which will go to its construction. When the foundation is required strength, it is possible to do laying the first wreath.

Following the previously prepared project home from a bar, the alignment is performed first and waterproofing basis. Then laid on top of the bottom row of the binding, which then need to be processed antiseptic. This should prevent the development of deformation of the timber. Floor and wall beams are usually used different cross sections. Thus, the floor it must have a cross section of 100 by 50 mm and the wall - 150 to 150 mm. On the first row laying on the edge of mount logs and have them installed subfloor which need to insulate on both sides.

Walling

The main thing to be done during the construction of the walls - it spread the timber rows. Each of them is connected between a specific pin called nog. Using it, the timber will not be deformed and displaced. This pin can be either metal or wood. Metal Nagel believes to be reliable, but at the same time it is more expensive. Timber itself must be prepared for connection, namely, it should be done right under the hole diameter Nagel. Between adjacent pins should be a distance of about 120 cm. The outer walls are joined by the method similar to the "tongue and groove" that will make the design more robust. To do this in one tool bar make the spike, and the other - the groove of suitable size. It turns out that the tongue and a groove in the adjacent alternate layers. Such a timber connection method is also called "warm corner". In addition, the angles are obtained windproof.

When the main walls are ready, they cut into walls, which used bar section 100 to 150 mm. If the width and length of the house more than 5.5 m, then on the first floor should be at least one partition, which will act as an additional support for the floor of the second floor. You can reduce the cost of construction. In this case, the cross section of the bars 40 to 40 or 50 to 50 made frame which is then sheathed with any suitable material.

roof Construction

The roof can be covered with any suitable material. For example, a suitable metal, roofing and decking. Before going into the roof, you first need to insulate the upper floor. When working on the floors the top floor and the roof battens are mounted, ceiling beams and rafters. And the installation depends on the design of the roof. Ceiling joists are made of timber with sides of 150 × 100 mm. They are placed in such a way as to protrude slightly from the base of the wall. Moreover, by mounting them on a rib between them should be slightly less than 0.9 m.

After mounting, the lags start assembling the rafter system, which must be reinforced with the help of racks, diagonals and rigels. For the manufacture of rafters, the boards of rectangular cross-section with parties 50 × 150 mm are used. Honey rafters are also respected by a distance of about 1 m. After installing the frame, you can start making fronts. For their manufacture, there is usually siding or a bar with the sides of 150 × 150 mm. After that, a rectangular section of 30 × 150 mm in size is mounted on the rafter.

Window blocks and doors

The windows are made one of the most recent. Moreover, when the walls are erected, no openings usually do. They are drunk only after the walls are ready. But even when the openings are cut, the window blocks themselves do not put the final shrinkage. Window blocks can be wooden or metal-plastic. As for the doors, they are mounted in the door frame, which is usually manufactured in advance. For this, the grooves are cut in certain places of ends. They are then laid a bar, which should be a little less in length than the height of the doorway. It is necessary so that it does not damage the shrinkage process. After shrinkage to this bar, the door is fixed. The door frame not only keeps the canvas, but also allows you to securely fix the doorway in the desired plane. This compensates for the deformation of the bar when changing the humidity of the material.

Wall decoration

When the house is erected from the glued bar, it is possible to start finishing work soon after the walls are ready. But still it is worth waiting for a while until shrinkage, which, depending on the humidity of the material, can last from several months to one and a half years. The higher the humidity, the more time it will take this process. It is worth noting that using even only high-quality materials during the construction, you will receive a relatively inexpensive house from a bar. The cost of finishing largely depend on what time during the year you are planning to conduct in this house. If there is quite a lot, then it is worth thinking about outdoor insulation, as an option of saving on the heating of the room.

As the house shooks between the logs, slots are usually formed. Through them may occur the loss of heat. Therefore, log cabins from an unpainted bar before finishing need to be caught, which is quite laborious. At the same time, the cracks are close in and outside by means of harness fiber.

If to build a home to choose a profiled timber, the dwelling is used as an inner and outer decoration. The layer of this coating is usually selected to its taste. Nevertheless, it should be borne in mind that the paint layer should also protect the wood from sunlight and moisture. Due to the properties of wood, the upper layers of the bar does not retain constant humidity. The same applies to the quality of the surface. Therefore, before applying paint, the surface of the bar is recommended to polish. In addition, it will make it better to apply a paint mixture.