To ensure comfortable living conditions in the house, it should be engaged in heat insulation. The maximum thermal insulation efficiency is achieved only with high-quality floor insulation. It can be carried out with the help of various materials. Now we will tell you how to insulate the floor by clay.

Content

Benefits of material

Ceramzite is a bulk granulated material made of burnt clay. For the implementation of thermal insulation works, this material has been used for a long time.

Despite the emergence of many new materials, the ceramzite has not lost popularity and now. This is due to the excellent technical characteristics of the material:

- slight weight;

- unpretentious in work;

- resistant to temperature differences;

- environmental purity;

- absolute fireproof;

- ease of installation work;

- excellent sound insulation properties;

- acceptable price.

The quality of the flooring for the floor directly depends on the correctness of the compliance with the process in the manufacture of material. Ceramzite is obtained as a result of exposure to the clay of a sharp heat impact. Low-melting clay is exhausted and covered by pores. The upper part of the granules is exposed to high temperature, as a result of which the material is obtained with a hermetic sheath.

Depending on the diameter, the following clay fractions exist:

- 5-40 mm;

- 40-50 mm;

- over 50 mm.

Preparation of the foundation

Regardless of the type of insulation of the floor with clay (on the ground, under the tie, with wooden floor), the surface preparation is pre-prepared. This process consists of three main stages:

- cleaning black floor;

- fixation of communications elements;

- waterproofing base.

Cleaning base

In most cases, the old floor is disassembly at this stage. Almost all items are removed because it is necessary to get to the maximum lasting base.

With the help of metal scrapers and brushes, the entire draft floor is cleaned from dirt and garbage. After that, on the basis, you can walk by a construction vacuum cleaner. Cracks are sealed with concrete solution, mounting foam or special glue.

Fixation of communications

To prevent damage to communications, they should be securely secured. This is done in one of two ways:

- by winding the cable and pipes with polyethylene, followed by the fixation of communication harnesses to the floor using tape;

- through the use of metal-plastic sleeves, in which all elements of communication systems are placed.

Waterproofing base

As a waterproofing material, you can use moisture-resistant mastic or dense polyethylene film.

For applying mastic applies a roller or a wide painting brush. To obtain the best thermal insulation effect, the surface coating with the material should be made in 2-3 layers. The drying time of the mastic is in the range of 2.5-3 hours.

If it is decided to use the polyethylene film, it must be installed by strips. Moreover, the bands are stacked, and their reliable connection occurs with the help of tape.

It is also necessary to envisage that the walls are covered with a special waterproofing tape (at an altitude of about 10-12 cm). Due to this, a smooth gap is formed between the wall and the screed, which serves to prevent thermal deformations.

Floor Warming Technology Ceramizite

After the preparatory work can proceed to the floor insulation expanded clay. There are three technologies of thermal insulation:

- under the screed;

- on the ground;

- under the wooden floor.

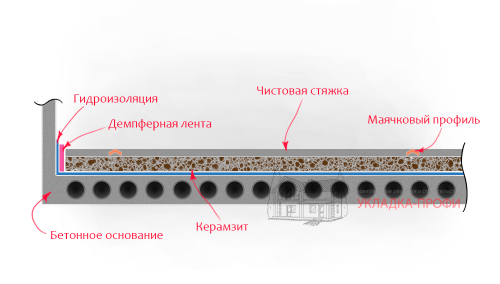

Warming of the floor under the screed

The screed floor with his hands expanded clay is the most optimal one surface with insulation in areas inaccessible to penetration of moisture.

The technology of thermal insulation works includes:

- installation of beacons;

- expanded clay backfill;

- pouring concrete.

Mounting of beacons under the floor to fill expanded clay made in the same manner as in the conventional apparatus concrete screed:

- partitioning the flat horizontal line;

- near the wall (opposite the door) installs the first lighthouse;

- fixing the remaining beacons produced on concrete mortar or self-tapping screws;

- for their alignment are building level;

- the distance between adjacent beacons is 0.8-1 m.

Further carried styling expanded clay. To create the first layer of material in a ratio of 1: 5 is mixed with cement mortar. The first layer of expanded clay is placed so that its highest point was located 2 cm below the beacons.

To give maximum strength screed is enclosed by the beacons mesh reinforcement. Then expanded clay covered with concrete mortar.

The only difficulty that will be faced in the process of concreting - keramzita property to surface. This problem is solved by using a trowel, which heater is recessed into the solution. After soaking a moisture keramzit effortlessly sink into the concrete column.

The minimum thickness of the screed must be 2-3 cm. Its filling occurs by level exhibited beacons over expanded clay layer. For leveling screeds and removing excess solution is used usually long, which is held between adjacent beacons.

Concrete screed dries for 3-4 weeks. During this period care is performed thereto (daily wetting) and protection from sunlight.

Warming of the floor on the ground

This technology is very similar to floor insulation under screed. There are only the following features:

- presence better waterproofing;

- laying more expanded clay.

Conducting high-quality waterproofing involves the use of thick polyethylene film. Moreover, a single layer is insufficient. He quickly rot. Typically lay three layers of waterproofing material, each of which is placed in the opposite direction.

As for the laying of more grazitis, this is due to the fact that the thickness of the insulation layer should be within 20-25 cm. The concrete screed must be thick from 5 cm.

Healing floor under the wooden floor

This process resembles thermal insulation work using mineral wool. It consists of the following steps:

- laying waterproofing material;

- installation lag;

- failures of clay.

With the insulation of the wooden floor, only one layer of polyethylene film is sufficient. After alignment I. montage Lag. Cropping is made of clay. The material should be located at the level of the upper part of the lag with the presence of a ventilation gap in 1 cm.

Some Soviets

To perform high quality insulation of the floor using clay, it is necessary to comply with a number of specialist recommendations. Here is some of them:

- To calculate the exact amount of clay, determine the load on the floor.

- Laying the waterproofing film is done in such a way that its extreme part turns into walls.

- If there is no possibility to purchase T-shaped lighthouses, then instead you can use old pipes or corner. The main thing is that they were smooth.

- The fastest frosting of the beacon exhibited is achieved with the help of alabaster.

- It is impossible to make a filling of the clay, while the solution under the beacons does not completely grab.

- After coating of the first layer of clay, it should be covered with cement milk.

- Wooden floor insulation is carried out by mixing 2-3 fractions of the ceramisite.

- The process of setting a claying screed is checked using a glass jar. At night it put on the tie of the neck down. If the bank is covered with condensate, then the floor should still be saved.

Video about flooring with clay: