Installation of warm water floors is a sufficiently difficult task. Especially if there is no experience in this matter. Most often, installation work on the installation of floors is trusted only by specialists. However, in order to save money, some home owners try to fulfill their own. In any case, efforts are worth it. After all, as a result, you can equip at home a truly favorable heating system that will last long and allow a lot to save. So, if you decide to install a warm floor with your own hands, then you will need to purchase the necessary materials and tools. After that, preparatory work is carried out, which cannot be underestimated. In particular, it will be necessary to prepare the surface of the floors. Moreover, it is desirable to adhere to the established requirements. Next, we will tell you more about the specifics of the installation of such systems.

Content

Characteristics of water heating

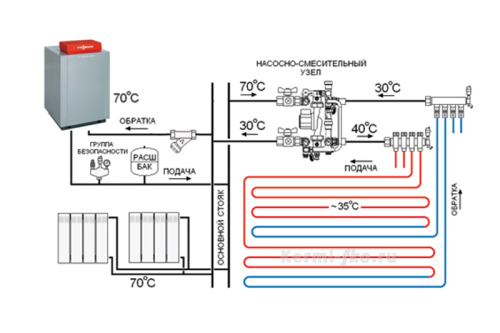

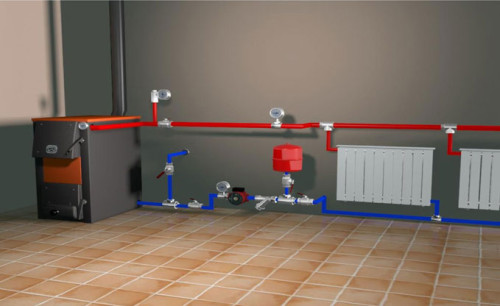

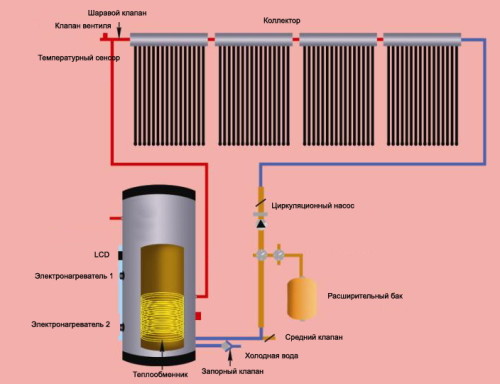

The basis of such a warm floor is pipes made of metal plastic or polypropylene. Water moves on them, which serves as a coolant. It is due to the regulation of the water temperature that the room temperature is controlled and installed. For this purpose, the system has a room thermostat. This is one of the main advantages of water heating. From the "strengths" there is still a small energy consumption, which, in turn, makes this system economical.

From the disadvantages, first of all, the complexity of the installation work should be noted. In addition, such heating is most likely not suitable for apartments with low ceiling. The fact is that the installation involves raising the level of the floor at least 12 cm. In addition, the appearance of the leaks during operation.

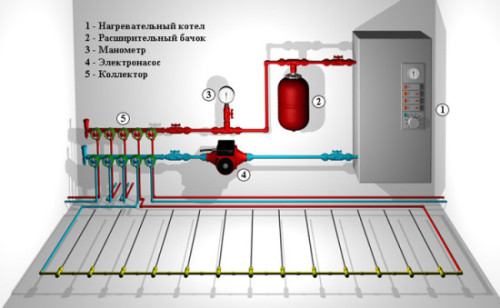

Consider shortly specific work and devices of this kind of heating. Thus, in the system of warm floors there is a boiler, pipe wiring and an adjusting system. In addition, the collector cabinet is installed. It offers a reverse and feed pipeline. For the proper operation of the system, special tubes are summed up to the corresponding issues. In addition, because The system is under pressure, valves are installed for excess air booming.

Selection of materials

Initially, you need to prepare all the necessary tools and materials:

- In particular, the water heating boiler and pump will be required. Sometimes they are one design.

- You will also need a ball valve to be installed on the boiler input.

- A collector is also required, equipped with a system for adjusting and regulating warm floors.

- In addition, part of the design of the warm floors of this type is necessarily a layout. Usually they are made of polypropylene.

- For laying the main layout you will need fittings. They are used to supply the pipes of the warm floor to the collector.

If the choice fell on polypropylene pipes, they are better taken with reinforced fiberglass. The fact is that pipes made of this material, but without reinforcement, will expand when heated. As for polyethylene pipes, they are not so strongly prone deformation. By the way, when laying the surface of heating systems, polyethylene pipes are the most common.

In the system of water heating under the floor, tubes are usually used, a diameter of 16-18 mm. The pipe must withstand the temperature rise of up to 96 degrees and the maximum pressure. It is not necessary to use expensive options at all.

To attach wiring to the main line, this part is used as a collector. It is a system with multiple discharges. The collector still serves to fence back and chilled water. In addition, there is a collector wardrobe in which two splitters are installed, each of them serves for different purposes. So, one is needed for adjusting and serving hot water. The role of the second is the collection of waste water from the system. The collector system also contains mechanisms for adjusting the flow, valves and a special regulating system, which allows for an emergency drain.

Water heating floor with their own hands

First of all, you should decide where the collector will be located. Perhaps you will have to install a special selection for him in advance. It is needed in order to be more convenient to control the warm floor.

Indoors need to make marking. It is best to do on special zones, 400 square meters. MM, which will help to take into account the temperature deformations of the screed arising from heating. The water floor is convenient to count with the help of an ordinary notebook in the cell. Marking on cells will make it easier to portray all the pipes in the room on the desired scale, and this, in turn, will facilitate the calculation of the desired amount of materials.

Next, the location of the system should be designed. So, next to the outer walls you need to put pipes of a larger diameter or make more indent. The fact is that in these places the system will be less effective. In addition, you should think in advance how the furniture will be placed, thereby you can save a lot of money to repair. Only after the careful implementation of all calculations and design, you can start work.

The order of work is as follows:

- The process begins with styling. If the floor has an old screed, then before laying the floor, it will need to be dismantled.

- In the process of forming a screed for a warm floor there are some very important nuances. For example, all available drops are more than 8 mm, it is necessary to thoroughly align.

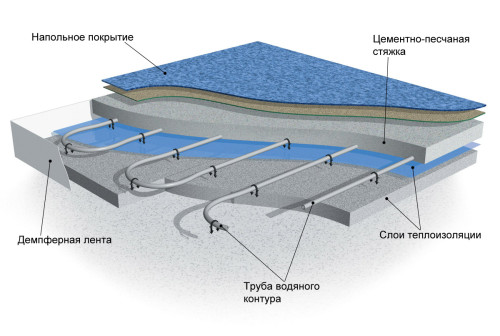

- When the screed is ready and dried, its surface must be cleaned, and then put a layer of waterproofing. When heated, the thermal extension occurs to compensate. For this purpose, you should fix the damper tape.

- To avoid heat losses across the floor, its base must be as follows. Moreover, insulation is chosen depending on the type of coating, the location of the room and the goal of heating. For example, a warm floor can use as an additional heating source. In this case, foam polyethylene is suitable as a heater, which is applied by a foil layer. In some situations, the heating is better to use foam or clamzit. For example, it is relevant for apartments located on the first floor of the house with a unheated basement and in the building standing on the naked ground. In other cases, it will be enough to insulate the floor with reservoirs of polystyrene foam.

- If the means allow you to make it easier to work, buying special polystyrene insulation in the form of a constructor with comfortable grooves for laying pipes.

- To reliably fix the heating pipes to the floor over the insulation, it is necessary to put the reinforcing grid. Using it, it will be possible to fix the layer of the screed, which will be closed by the heating system of the floor.

- Next you need to do everything to compensate for thermal expansion. To do this, a damper tape is laid around the perimeter of the room.

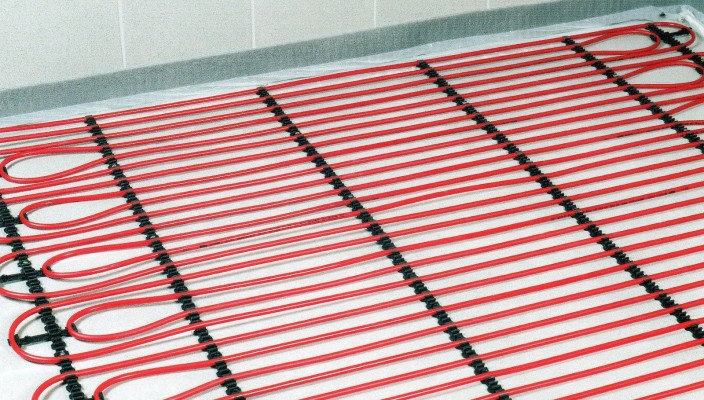

- After that, you can do the pipes themselves, or rather, their laying. There are several installation methods. Most often it makes a snake or spiral with a shifted center. The pipe reinforcement grid is usually fixed by plastic clamps. At the same time, there should be no more than 1 m between adjacent fasteners.

- When the floor is laid, it can be connected to the collector. One end of the pipe is connected to the return opening for waste water, and the second to the outlet of the heated water. Tubes are fixed through specials. The length of the contour varies depending on the power of the system. Optimal dimensions must be specified in the instructions for the installed heating system.

- Next, you should lay a new outline. One of the ends of the looped circuit must be connected to the return collector. On the tube passing next to the seam, it is recommended to wear corrugations.

- When the installation is completed, before starting operation, you need to check how the water floor works. In other words, it is necessary to make crimping. For this purpose, you need to turn on the boiler for the maximum power. As a result, the pipes should be received in the pipes, which will be supplied under certain pressure. Most often at maximum power, this pressure is 1.5 times higher than the norm. During such testing, you need to carefully check each connection, literally every meter of the pipe. It is important that the pressure tube is not shifted by clamps. The duration of such testing should be at least a pair of hours.

- Next is the floor screed. It is advisable to use ready-made compounds for floors with water heating. When the screed is laid, the floor will become above about 70 mm. When pouring a screed in heating pipes, cold water should flow. At the same time, it should be supplied under the "optimal" pressure.

- When the screed dry, it's time to put on the surface of the tile. If the floor is lined with a laminate or wooden flooring, then the pipes are usually paved without a screed under lags. In particular, the laminate for lags usually lifted the OSB plate or plywood sheets. In the same case, small holes are made in them to improve heat transmission.

Sometimes a similar system is easier to install on lags and without a screed, but this approach is not recommended. Experts advise to make a screed in any case, because It increases the service life and efficiency of the system.

Important nuances when installing water heating system

- Pipes can not be laid until the basis of the floor will be prepared. The most important thing is that it was flat enough, because From this depends on the uniformity of the surface heating.

- There are many ways to align the floor. One of the most suitable is the use of self-leveling mixtures.

- After the alignment of the floor, it is necessary to arrange protection against dampness, i.e. It is necessary to lay a layer of waterproofing.

- No less important thermal insulation, a layer of which should be sufficient for heat load. How this load is higher, the thermal insulating reservoir should be thicker.

- As for metal-plastic pipes, which are used to transfer the coolant, it is desirable to choose a pipe with a diameter of about 20 mm.

- In the course of operation in the joints of the joints are possible. So that this does not happen, each laying loop is recommended to do from a solid pipe.