The quality of the window design and the duration of operation depends largely on the installation. To set the window correctly, its measurements must be performed in accordance with all the requirements. The definition of accurate dimensions will help to avoid difficulties and surprises in the process of assembly work. Each design is manufactured in accordance with the sizes of a specific window opening.

Content

- Features of the process metering process

- Types of measurements

- Determination of width and height indicators

- Basic measurements

- Meaning in mind

- Features of the measuring process of structures with a quarter

- Execution of window measurements without a quarter

- Sealing windows

- Conclusion

- Measurement. Video

Features of the process metering process

Incorrectly made measurement may entail significant problems when installing. For example, if the frame size exceeds the parameters of the opening, it will take its expansion, which will require additional expenses. If the window is small, after installing it is formed slots. In this case, to correct the situation will need to apply the foam core or increase the slopes. It is also associated with additional costs and waste of time.

In addition, there is a chance that such a window will not cope with its functional task. But in the presence of certain knowledge, you can perform measurements yourself and in accordance with all the requirements. There are certain rules focusing on which you can get a clear idea of \u200b\u200bhow to measure the window.

Types of measurements

There are two measurement techniques, consider each of them in more detail:

- The measurement, which is performed before, makes it possible to obtain an idea of \u200b\u200bthe configuration of the future design, the cost of production and installation work. Also, the preliminary measure will help determine the use of additional elements, such as windows, rollers, mosquito nets, lowers.

The results obtained will allow the budget with maximum accuracy, which will be required for installation work. If the preliminary measurements are made with the necessary thoroughness, the final price for the design will have minimal differences from the previously indicated value.

- Performance of measurements for the manufacture, which relate to the second form, provides the manufacturer with complete information about the size of the windows. This measurement is the most responsible stage of the work, since all the nuances are finally determined when it is fulfilled: the profile type, configuration and parameters of the visor, the sizes of the window sill, the presence of a mosquito net, fittings. When the manufacturing process begins, it will be impossible to make changes. Therefore, this stage should be considered specially liable.

Undoubtedly, the modern construction industry offers windows from various materials. However, it is metal-plastic structures among all varieties of windows. The wide demand of these products is due to a significant amount of positive qualities, among which such: durability, resistance to negative climatic influences, high indicators of heat and sound insulation, a wide selection of forms and colors, ease of care. Thanks to the special manufacturing technology, modern plastic structures meet all environmental safety requirements.

In houses built on the basis of panels, the openings have the same dimensions, and in brick buildings they, as a rule, differ in size. Measurement of windows is made on both sides of the building. These indicators allow you to determine which depth is the opening. If there is a skew, the opening parameters must correspond to the skew size. After the measuring actions are completed, it is necessary to compare the final data with the opening parameters inside the building. This will give the opportunity to identify errors in measurements, if any.

Determination of width and height indicators

Regardless of the type of construction and window opening, the windows can be measured on the basis of dimensions in width and height. To do this, such features of the process should be taken into account:

- To carry out the correct measurement of windows in width, it is necessary to add 5 cm to the width of the external slope. When working with an uneven wall, add up to 3 cm.

- To obtain the most accurate indicators, the design parameters must be less than the opening when measured indoors.

- If an installation window is installed with a balcony door, the window and door parameters should be measured. The door width is determined at the bottom. Between the end of the box and the stone base, the gap of 2 cm should be formed to accommodate the insulation.

- To measure the height, it is necessary to determine the distance between the running base and the upper outdoor slope and subtract from this result 2 cm. This will be required to use the mounting foam.

- In order for the window to start a quarter from above to this indicator, 2-2.5 cm should be added.

- If the installation is planned with the windows board and the tump, therefore, with a coaching profile, it is necessary to take 3 cm on the final size.

Basic measurements

Before entering the work, you should familiarize yourself with the rules for the preparation of the measurement sheet. The formation form of PVC windows is drawn up as follows. It is necessary to draw a small table in which the following items must be present:

- length and width indicators of the windows;

- window parameters;

- vehicle size;

- parameters of finishing PVC panels.

Consider several rules that will help to measure windows with your own hands:

- The window must be a bit already internal opening. Window parameters in the absence of a profile must be less than the distance that separates the slope and the windows. When measuring, it is necessary to take into account all the irregularities and defects of the opening and walls. For example, you can encounter lack of symmetry or outlook.

- The window according to its size should exceed the parameters of the opening in height and width by 2 cm and 3 cm, respectively. This is necessary in order to avoid the formation of gaps between the opening and the box when performing installation work.

- Measurements must be performed both with internal and outside. Only in the presence of these indicators you can determine the depth of a quarter of the existing opening. The frame must give way to the way in size so as not to rest in it.

- If an error was made when calculating the frame parameters, it is possible to correct the situation using special plates. These elements are made from the same material as the frame. With a significant error in the calculations, the so-called "black frame" is used. This name does not correspond to the color of the structure. It is installed between the frame and walls where the visual perception is hidden.

- To determine the width of the measurement, you need to be at the bottom, in the middle and above. Next, it is necessary to subtract several centimeters to the gaps from the resulting number, the last result will correspond to the frame parameters.

- The height is also measured at several points: on the right, on the left and in the middle. In this case, also from the smallest value is a certain distance for gaps and a standal profile. The resulting indicator corresponds to the height of the future design.

Meaning in mind

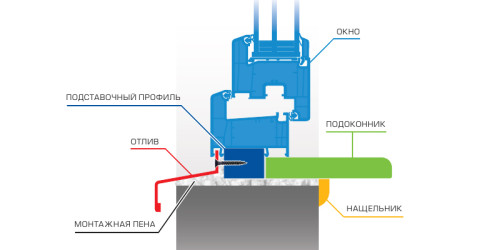

From the outside of the window, it is necessary to install a tump, which will be required for precipitation. For this reason, the location of the lower edge of the window box should not be lower than the outer edge of the opening. This will avoid overlapping holes for water removal on the outside of the box. In addition, it is necessary to seal the joints between the frame and the sampling, as well as between the frame and the windows. For this you can use silicone.

Singing is recommended to mount under the window. In this case, the water can not be seen in the connection sections. The windowsill can be set to the window or for it. It is more preferable to name the last option. Since in this case, the connection strength will be significantly higher and the moisture will not flow through the joint. Also when installing the windowsill, it is recommended to make a slight tilt at 3 ° C to avoid the flow under the condensation board.

After performing measurements, you need to compare the parameters of the future design and the internal dimensions of the opening. If an error is present in the calculations, it will make it possible to detect it on time. The space in the junction of the frame and the wall should not exceed 3 cm. Especially this rule is relevant for large windows. It will not be difficult to achieve the desired result. As a rule, manufacturers, in addition to the main parts required for the manufacture of the window, include additional profile specifically provided for this purpose.

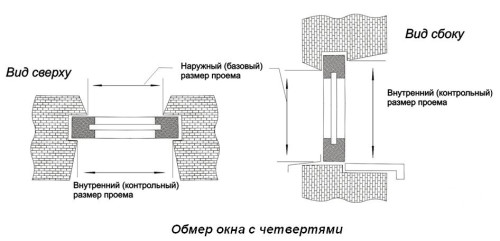

Features of the measuring process of structures with a quarter

A quarter is called the protrusion in the Pollipich, which is from the outer sides of the window. The installation of the frame is carried out. The method of measurement is made taking into account such features:

- The battered holes in the homes of this type should go 30 mm on the outside for slopes on the sides and from above.

- The width parameters should be measured, focusing on the slope from the outside. To this value you need to add 60 mm to ensure the location of the windows in a quarter from the side of the building and the street.

- In the presence of irregularities, it should be added to 40 mm.

- After determining the width between external slopes, it is necessary to make sure that the resulting indicator does not exceed the space between the seats of the slopes inside the building to the frame.

- The width frame must correspond to a similar indicator of the opening indoor.

- Next, determine the height rate. To do this, you need to measure the space from the slope from above to the running base and add 30 mm to this value so that the window can go to a quarter from above.

- If you plan to install a window design with a profile, you need to take 30 mm from the height indicator. This distance corresponds to the size of the profile.

- Make sure the correctness of the measurements can be made in this way. It is necessary to compare the height of the frame without taking into account the profile parameters and the space from the upper slope to the sub-circuit board. It is necessary that the frame is in its height correspond to the distance.

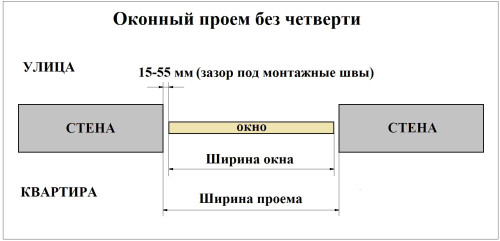

Execution of window measurements without a quarter

The width in this case is defined as follows:

- Measurement is carried out both in the lower and upper sections of the opening. It follows the width from which 30-40 mm is taken to apply foam. The result obtained and will correspond to the width of the window.

- When determining the measurement height, it is necessary to perform on the left and right of the opening.

- From a smaller result, up to 40 mm for foam, as well as 30 mm, which correspond to the profile height. The final indicator will be the height of the window.

Sealing windows

The outer seam between the wall and the frame is mandatory to be embedded by means of sealant before installing. Especially in cases where the deaf sash is present in the design. After setting the access window to the outer seams will not. If the seam width is small (up to 15 mm), it is possible to seal with the help of silicone sealant. There are cases when due to the irregularity of the wall, the seam width reaches 5 cm. With this indicator, the best option will be plastering.

Today, polyurethane foam is widely used for sealing. It provides good sound and heat insulation, accepts and distributes mechanical loads, easy to use and has a small value. But it is also necessary to remember the disadvantages of this material. Foam does not have resistant to ultraviolet, its integrity is disrupted under the influence of sunlight. For this reason, the foam should be coated with a layer of plaster composition, sealing agent or paint. Studying these rules will help get a complete picture of how to measure the plastic window.

Conclusion

The measurement procedure is one of the most important steps in the installation of window structures. The manufacture of the window will be carried out on the basis of the results obtained, therefore this process should be taken with due responsibility. Installing a design that does not correspond to the size of the opening entails certain difficulties, the elimination of which will require additional costs. In order not to encounter such consequences, measurements should be carried out with special care. The measurement procedure provides for several stages and has its own characteristics and rules, following which will help to obtain a qualitative result.