The polyvinyl chloride has long established itself as a safe with the neutral properties of the material successfully used in the medical industry and in the food industry, as well as for household needs. Currently, outdoor vinyl tiles are widely demanded. Since technology does not stand still, an improved variant of this material is a quartz vinyl tile, which contains 60-80% of natural quartz. This wear-resistant and durable floor covering allows you to imitate various natural textures. Due to its versatility, quartz vinyl tiles can be used in rooms of various purposes, as well as on open verandas.

Content

What is a vinyl tile quartz

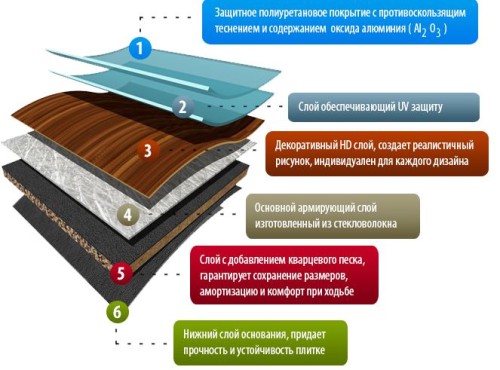

This finishing material is an outdoor coating consisting of several layers:

- the upper layers of transparent polyurethane with the addition of aluminum and polyvinyl chloride oxide serve as protection against mechanical damage in the form of scratches, as well as abrasion of the film;

- under them is a fiber-optic layer - a decorative film for applying a pattern that is responsible for the coloring of the tile;

- for quartz, the vinyl layer accounts for the main mechanical load on the floor covering. It, in turn, surrounds the glass cholester, providing the reinforcement of the tile and the increase in its ability to resist the deformations;

- the lower balance sheet of vinyl is used to absorb vibrations and provides mechanical coating strength.

Made by hot pressing This heterogeneous coating is characterized by high strength and wear resistance. In addition, quartz vinyl tile provides additional sound and thermal insulation. Currently, this material is becoming increasingly popular as an outdoor coating for various premises, including with high intensity of operation. Thanks to excellent performance and the provision of broad opportunities for decorating, quartz vinyl tile gradually sweating such traditional materials such as linoleum, laminate, as well as parquet and ceramic tiles.

Vinyl tile quartz properties

Due to the presence of special additives, including a significant amount of natural quartz, quartz vinyl tile is durable, sufficiently hard, and at the same time flexible and plastic material. The homogeneous and smooth protective layer of polyurethane with the addition of aluminum oxide provides ease of care. Quartz Vinyl coating is hygienic, does not absorb smells, not exposed to the reproduction of fungus and mold, it is easy to clean (you can safely carry out wet cleaning using suitable domestic products). Also mention the impact resistance of the vinyl tile quartz - this material gently springs in mechanical effects. In case of damage to the tile, which came into disrepair, the coating element is easy to replace.

Safety and neutrality PVC has long been proven by numerous studies. Due to the unique composition with a content of about 80% of natural quartz, a high degree of purification, a quartz vinyl coating is characterized by a high level of environmental friendliness and is a hypoallergenic, absolutely safe material that does not distinguish toxic evaporation even when heated. Quartz vinyl tile to the touch significantly warmer tile, it is nice to walk barefoot, without fearing to catch a cold. Thus, a quartz floor covering can be used to arrange residential premises, including bedrooms and children's rooms.

Among the advantages of using vinyl tile quartz should also be noted:

- the versatility of this material - quartz vinyl flooring does not respond to temperature differences, can be used in conditions with enhanced operation requirements, with a significant humidity, the presence of a "warm floor", as well as in the passing premises;

- thanks to 100% moisture resistance, quartz vinyl floor tiles can be laid in rooms with reinforced humidity mode (bathrooms, bathrooms, pools and basements, as well as on terraces and balconies). Such a tile does not suffer from water from entering and characterized by anti-slip properties;

- quartz Vinyl coating does not carry out electricity, is characterized by fire safety, as it does not ignite and does not support combustion;

- this material is distinguished by wear resistance - the service life of such a coating is several decades. Quartz Vinyl tile is resistant to scratches from sharp heels compared to cork and parquet (although the laminate is somewhat inferior in this place), there are no footprints from the furniture legs. This material is perfect for office space, as it does not have damage from the movement of furniture on wheels;

- providing wide opportunities for decorating - Quartz Vinyl tiles reliably imitates the pattern and texture of stone, wood, ceramic tiles and other materials, creating the impression of natural coating. The drawing of the tile is not subject to abrasion, as well as burnout under the influence of ultraviolet rays.

The price of vinyl tile quartz is quite accessible, and although it is somewhat higher than, for example, the rolled linoleum, these costs are quickly paying off during operation. It is worth noting that well-proven European manufacturers give a 100% guarantee of the quality of their goods confirmed by hygienic certificates. Unlike them, unscrupulous manufacturers can increase the content as part of plasticizer tiles, providing tile flexibility and compounds. With an abrasiveness of plasticizers, hending the process of production of tile, its geometrical parameters deteriorate, in addition, one can observe the appearance of the so-called "lunar tracks" in the places of increased abrasion of the material. It should be noted that it is possible to determine the poor-quality fake on a fairly sharp unpleasant odor, which comes from the tile material.

Unlike the parquet, for the installation of which is required to provide a substrate, a quartz vinyl flooring in itself provides reliable sound insulation and acoustic comfort. This is important if there is a small child in the house, as well as for amateurs to walk on heels. The sound insulation properties of the vinyl quartz is no worse than the cork coating. Thus, preferred this type of tiles, you can save money to the substrate. In any case, the Quartz Vinyl provides a higher level of insulation from noise and warmer to the touch compared with parquet, laminate and ceramic tiles.

How to lay quartz vinyl tile

Laying quartz vinyl flooring does not represent a special complexity. This tile material is distinguished by small sizes, significant flexibility and plasticity, is easily cut by a sharp knife.

The following varieties of vinyl tile quartz are presented on sale:

- the glue tile is an inexpensive tiled material that needs to be laid on glue. Reliable tile adhesion with floor provides dispersion acrylic or contact glue;

- tile with lock (groove-thicket) compound that simplifies the laying process. With this method of laying, the tile material is connected to each other by snapping into the lock (both when laying a laminate), without clutch with a rough floor;

- self-adhesive tile - on the back of its manufacturer inflicts a special adhesive composition, providing fast and reliable adhesion with various solid surfaces.

Depending on the specific needs, you can buy a quartz vinyl tile of various sizes and thickness, rectangular and square shape. From the selection of the type of compound of quartz vinyl tile will depend on its laying.

The following tools and materials may be needed to fulfill work:

- line, simple pencil;

- roulette;

- cord;

- cement;

- putty;

- primer liquid;

- a toothed spatula (with small teeth) A2, as well as an acrylic adhesive composition (except when self-adhesive or with a locking tile is used - a rubber hammer will be required for it);

- roller

Preliminary preparation

Initially, it will be necessary to prepare a draft surface under the installation of vinyl tile quartz. To do this, remove the garbage, clean the floor from dust and spots. The concrete surface must be aligned - for this it will be necessary to close the existing potholes and cracks, or pour a concrete tie. After that, the floor surface should be primed to improve adhesion with glue and wait for it.

In the case of the presence of a wooden base of the floor, covered with plywood sheets, GBL or oriented chipboard, it is necessary to stick the differences to achieve the alignment of the final surface. In addition, you will need to shap the existing defects in the form of cracks and cracks, remove dust. The styling of the quartz of the vinyl tile should be performed in the presence of a lined rough surface of the floor with humidity no more than 5%. The permissible temperature in the room when performing work - from 15 to 30 ° C.

Stages of work

Prior to the start of laying work, you should familiarize yourself with the manufacturer's instructions for laying tiled material. Before starting the laying, it is recommended to modify the future picture, laying out the tile to determine the optimal installation method. This material is starting to lay out from the center of the room, in the direction from themselves, in the sector most distant from the entrance. Different laying schemes are possible - at an angle to the wall, in the disintegration, christmas tree, and other fairly interesting options. If you want to cut the tile, it is applied to it and make a slice with a sharp construction knife, then bend and then finally cut.

When laying a vinyl flooring quartz, you will need to perform this sequence of actions:

- First, you should apply marking - for this it is necessary to determine the middle of the two opposite walls and connect these line markers. Through the center of the resulting segment, black is another direct strictly at right angles to the previous line. In this way, we get markup in the form of four rectangles, which will serve as landmarks when laying tiled material.

- After that, you can proceed directly to the laying of an outdoor coating:

- the self-adhesive tile is recommended to be laid at a temperature of 18-25 ° C. It should be allowed to the joint, without leaving the gaps. They are allowed only at the edges of the coating at the walls (these gaps should not exceed 3-5 mm);

- to lay the adhesive tile, you will need a spatula with small teeth to apply glue and leave it in this state for 10-12 minutes so that the excess of moisture evaporates and the composition has acquired the necessary viscosity, and then glue the tile material without gaps, close to each other. After that, it will be necessary to walk on top of the roller in the direction from the center to the edges of the tile to remove the air from the coating and improve the grip;

- the locking compound is performed without much trouble after applying markup (it will be necessary to armared with a rubber hammer for rigging material).

- After laying the tiles, it is necessary to wipe the tissue napkin moistened in alcohol, excess glue from the surface of the tile. Quartz vinyl coating is allowed to walk shortly after installation. Place the furniture on it is not earlier than a day when the glue grabs efficiently. You can carry out wet cleaning not earlier than five days after laying the tiles.