Prices for electricity and heating are growing from year to year, and regularly people come up with ways to save - use alternative energy sources, cheap fuel, invent transformations, etc. For owners of country houses, the problem of heating is particularly acute, because to warm up a large house in two or three floors much more difficult and more costly than an apartment. One of the most popular ways to get warm housing and not to spend a fortune for this - to purchase an induction boiler. Even better - to gather it with your own hands, especially since this is not so difficult. In this article we will tell how to make an induction boiler for your own home.

Content

Principle of operation of the device

If you compare the induction boiler with classic heaters, it becomes obvious that it consumes electricity much more careful and more efficient. Under current prices for utility services, such a device is a great way to save without prejudice to the comfort.

A huge advantage of the induction boiler of heating is its absolute environmental friendliness and harmlessness to the health of people and animals. During operation, it does not release toxic substances or severe radiation (not stronger than the usual kitchen microwave), so such models are actively used by supporters of eco-life.

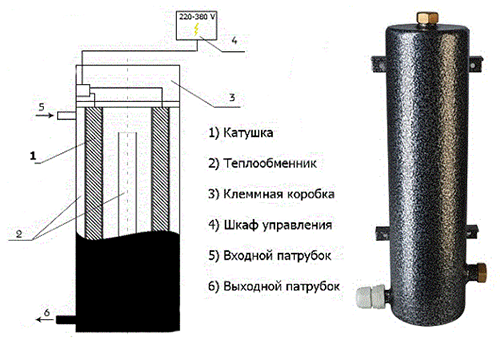

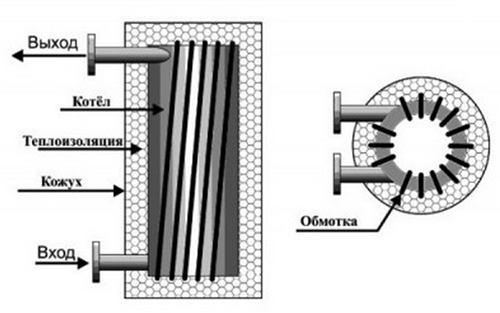

The simplest design of the induction boiler is an electric converter consisting of two parts:

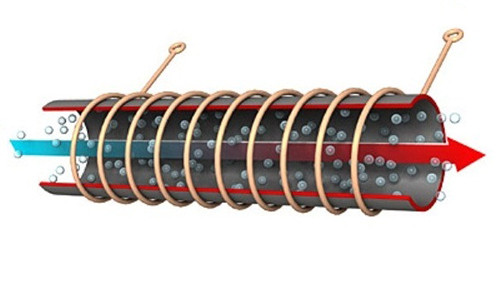

- The primary winding is inside and is aimed at converting electricity to vortex currents. It sends the resulting vortex field to the secondary outer part.

- The secondary winding serves as a heating element and an inductor housing at the same time. It accepts the electromagnetic field from the internal winding and transmits it to the coolant. As a coolant can be water, antifreeze, butter or any other electrically conductive medium.

Also, the structure contains nozzles that introduce a cold coolant and remove it after heating. Accordingly, two nozzles need for one induction boiler. If you have been removed to make such a device with your own hands, then the "cold" pipe must be installed on the introductory portion of the highway, and "hot" in the feeding point of the water supply.

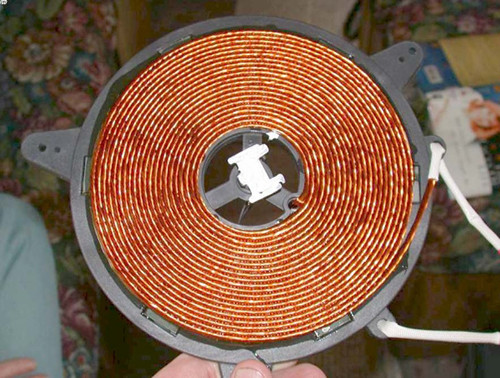

The external winding, as we have already said, is simultaneously the inductor hull. But in addition to it, there is also a dual wall core, electrical insulating and a layer of insulation. The main difference between industrial and household boilers of heating lies in the body of the case. In industrial models, it is equipped with a cylindrical winding, in domestic - toroidal copper wire, wound on the pipes from ferromagnetic steel with a thickness of the walls greater than 10 mm. This design can significantly reduce the mass of the device itself, make it more compact and at the same time increase productivity. Due to the lack of heat loss, the coolant receives almost 100% of energy.

Induction boiler device:

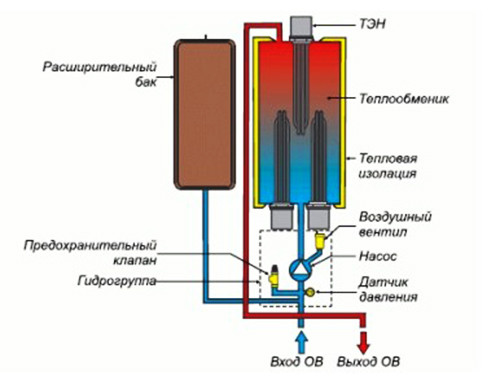

- Water or oil is supplied to the heating part through the cold nozzle.

- Electric current goes to the internal winding.

- A voltage is formed, exciting vortex currents.

- These currents go to the external winding and warm the core.

- Due to the rapid heating of the core, the entire area is very soon warm, and the heat obtained affects the coolant.

- The heated heat carrier goes on the "hot" nozzle and heats the room.

Since the removal of hot heat carrier is carried out continuously, the induction boiler simply cannot overheat. In this regard, it is completely safe. Another important advantage is the lack of heating surfaces in such an instrument, which are very "loved" to break or can be burned about. The detachable connections are not used here, and therefore the possibility of leaks is excluded. Scale in the boiler is also not formed, because it constantly vibrates. Vibrates does not mean the noise - the induction boiler is completely silent, and it can be installed in any room.

Will summarize the topic of efficiency and ease of operation of the induction boiler Video below:

The simplest boiler do it yourself

Make an induction boiler with your own hands really even without special education and professional skills. Nevertheless, before proceeding to work, it is recommended to carefully study the theoretical part, prepare all the necessary tools and materials, and also choose (or develop yourself) assembly plan. With the last item, the newcomer will be difficult to cope, so we prepared several detailed schemes of the induction boiler with our own hands that you will find at the end of the article.

The main problem of apparatus with different temperatures is to create a reliable and durable heating element. A excess amount of energy is formed here, which is either transmitted directly, as in the phenomena, or is converted into something other, as in the induction heaters of the vortex type.

If you look at the situation purely theoretically, the simple boiler can be collected from a conventional large pan, tightly closed on all sides. Two tubes will go to this pot ("cold" and "hot" pipes), a pump and join the expansion tank. Pipes must be combined with a chain of radiators, and the housing, that is, a saucepan, put on the gas stove. Now you can pour the coolant (water, oil, antifreeze), turn on the pump and light the gas. Of course, the performance of such a "induction pan" will be quite low, but it visually and intelligibly displays how the boiler works. If you make such a boiler from cast iron or steel tank and turn it on into the heating chain, then you can warm up a 3-room apartment, but not a private house. The consumption of electricity will reduce the maximum of 2.5 kW / h, while the tanne electrocotels "eat" as many as 6 kW / h.

Useful advice: For a successful and rapid assembly of a homemade induction boiler, prepare a welding inverter. With it, you can make a sealed generator body and securely connect nozzles. The simplest model of the inverter is suitable, which you can find in a construction store. Well, if the device will be a current adjustment function. The power of the middle inverter is 15 amps, but for the manufacture of an induction boiler it may not be enough.

In addition to the inverter, you will need a rider or wire with a thickness of 7 mm. It will need to cut into segments of about 5 cm long. You can use a thick-walled polypropylene tube with an inner diameter of no more than 50 mm. It will be simultaneously the basis for the coil and the heat pipelove sector for water, oil or antifreeze.

The specificity of the assembly of the induction boiler do it yourself:

- The heater will be attached to the heating system of the house with special adapters - "hot" and "cold" nozzles. The latter should be welded to the base of the case. To do this, put a metal grid on the bottom of the plastic tube. This grid will play the role of the barrier for pieces of wire.

- Cut the wire on the segments and pour them into the pipe so that they completely filled themselves the inner space to the top.

- Close the top of the pipe by another piece of metal mesh.

- The main heating element of the heat generator is the coil. For its manufacture you need a copper enameled wire. Swim on the plastic pipe case exactly 90 turns. Watch that they lay exactly and neatly with a little distance from each other.

- After assembling a homemade inductor, you can proceed to the system connection. The unit is obtained very compact and simple, and it can be connected to almost any point of the pipeline. To do this, cut part of the pipe from the system and in the resulting incision to install the inductor through the "cold" and "hot" nozzles. You can only start the device if there is a coolant (water) in the system), otherwise it is simply melted from overgrown.

Useful Tip: Make an induction electric boiler safer to use, isolating all open sectors of the copper coil with protective materials that do not conduct a current.

The cost of such a homemade heating device is simply ridiculous compared to almost similar factory models. From the disadvantages, it is possible to distinguish the nonesthetical appearance and modest sizes, but if desired, it is fixable.

Modified model

The induction boiler described in this chapter will make a little more difficult, but its productivity is at times exceeding the model we have said about. For a successful outcome of the case, you need to have professional work skills with a welding machine, have a three-phase inverter. Well, if it is with a stationary fastening.

The design of this inverter consists of a pair of larger and smaller diameter pipes, welded in each other. If we consider it from the end, then the pipes form a "bagel". This "bagel" will perform the function of the core generating an electromagnetic field. At the same time, it will serve as a heating element. If in the first case, a polypropylene tube with wire pieces was used, then the design is more powerful and reliable here.

Copper winding should be wound directly on the housing - so you will get higher performance and keep the low weight and compactness of the device. Nozzles should be boiled into the lower part of the case. The heating system will be heated automatically when the winding and coolant is in contact.

In the image below, you can see a diagram of a modified vortex induction boiler:

Of course, work on such a boiler will take more strength and time, and the cost will be higher, but the effect will pay off all in full swing. Such a device will warm up the whole house and will serve at least 20 years without maintenance and repair.

Safety

Getting Started on the creation of your own heating boiler, remember that absolutely safe energy and energy generators do not exist in nature. You can reduce the risk, but not eliminate it completely. Therefore, if there are children at home, make them so that they could not get to the apparatus.

The following useful safety recommendations will help you avoid discomfort when operating a homemade vortex boiler:

- If you installed the heat exchanger in the bathroom, it is better to turn it off while swimming. In the process of work, it produces microwave impulses that can harm health if they are nearby from their source for a long time (a distance is less than 50 cm).

- To isolate most of the microwave emissions, make a cellular screen from a magnetic material around the instrument.

- Do not store batteries at home. To do this, it is better to take a corner on the balcony, in a barn or in the attic.

- The induction heater can only be used for the heating networks of a closed type, that is, where the coolant moves through the pump operation.

- The device is safe only for pipeline wiring from polypropylene or plastic and cannot be used for old cast iron pipes.

- Install the boiler at some distance from the surfaces of the floor, walls and ceiling. So, from the floor should be at least 70 cm, and from the wall - 25-30 cm.

- To emergency reset air from the heating system, it is recommended to install a subversive valve.

The induction heating boiler can significantly save electricity. This article is especially useful for those who live in a private house and does not want to pay for exorbitantly high heating bills in the cold season. But the urban residents will not know how to live warm and cheaply among systemally growing tariffs.