One of the most sought-after ways to fulfill finishing work during the construction of your own house is the application of plaster. A variety of ready-made mixtures and recipes for self-preparation of a solution of handy materials makes it possible to perform the entire scope of work of this direction without the use of additional funds.

Content

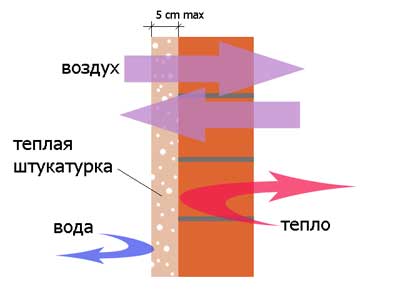

Of particular attention in this group deserves warm plaster, reviews about which confirm the actual cost-effectiveness and the profitability of such a decision. To more clearly understand what exactly is the material of this type, what advantages gives its use, find out the subtleties of the application technology, read below the outlined information in which all the nuances of its use are fully disclosed.

Features of the composition

Warm plaster consists of several ingredients of the following type:

- The base is a binder, due to which the necessary consistency is achieved. This group includes the following materials:

- cement;

- gypsum;

- lime.

- Filler to enhance thermal insulation properties. Most suitable materials for this purpose:

- foam glass;

- polystyrene foam;

- perlitic sand.

- Polymer-based additives for the correction of the density of the solution and the speed of drying it. This category is presented mainly by substances of artificial origin.

Important! Regardless of whether you decided to prepare a solution for warm plaster on your own or buy a finished product, in the high-quality mixture there must be components from each group. From the last category, not one type of substance is sometimes used, and several, depending on the requirements for the technical characteristics of plaster, surface base features and the selected solution of the solution.

What to choose a type of filler?

It is the type of filler that largely determines the thermal insulation and noise insulating properties of the plasters of this group.

To choose a suitable view of the solution, read the most important features of some materials of this category, which are in constant demand:

- Polystyrene foam. This material until recently was the most popular for the implementation of good thermal insulation, including as a component of warm plaster. The addition of polystyrene granules significantly increases the frost resistance of the decorated coating, due to which the solution is applied to this component for the facade walls of the house. The main drawback is that during the fire it also gives in to burning, and, at this moment, the substances allocated are characterized by special poisonousness.

Important! It is because of its toxicity and properties of maintaining combustion with the advent of better materials, which are stated below, the interest of consumers and professional builders to it gradually decreases, even, despite the fact that the cost of polystyrene foam is significantly lower.

- Wood sawdust. Excellent option if the main goal is the maximum savings. The effectiveness of isolation during their use will be lower, but minor cash costs and natural origin provide solid demand when preparing warm plaster.

- The foam glass is made of quartz sand. Under the influence of high temperature, the material acquires a cellular structure. The foamglass perfectly pushes moisture and does not ignore. The level of thermal insulation of this material is either somewhat higher than the heat insulation indicator when using sawdust, depending on the quality of the feedstock.

Important! Despite the hygroscopicity, the surface treated with warm plaster with such a filler does not need additional protection.

- Perlite is obtained with thermal processing of volcanic glass. The effect of high temperature in 1100C leads to a fluid intimidation, due to which, after the frozen, natural porosity is formed. This ensures a good level of thermal insulation when adding this material to the plaster.

Important! If you prefer exactly this filler, think over the option of finishing finish to protect the pores from the garbage to the garbage.

- Vermiculitis. This mica is also prohibited when heated and the total mass increases significantly. After firing, the vermiculite acquires a scaly structure, which provides the ability to use it as a heating component. It is advantageous to this substance, as well as perlite, absolute non-toxicity and non-causing.

Important! The withdrawal of such plaster is also a high level of hygroscopicity, which is determined by the finishing surface treatment.

What are the advantages of using warm plaster?

To understand why it is advantageous to fulfill the stucco finish with your own hands, look at the given advantages that distinguish both the material itself and the surface processing process:

- Environmental purity of substances used for the preparation of the mixture.

- Low thermal conductivity indicator, which makes it easy to isolate the room without applying additional materials.

- Good vapor permeability and moisture exchange, due to which humidity circulation naturally occurs and the stability of the microclimate is maintained.

- The minimum risk of cracking in the created coverage even after a long service life.

- A high level of fire safety due to the fact that the substances used, all without exception, have a non-combustibility.

- Increase indoor insulation indices, regardless of whether heated plaster was applied inside or outside the building.

- An unfavorable environment for the emergence and reproduction of various harmful microorganisms, for example, mold.

- The possibility of its use for decorating surfaces or as a screed.

- The ease of application process is not only due to the simplicity of the technology itself, but also due to the high performance of adhesion.

Important! Separately, we note the financial profitability of such a solution, since the decorative finish is quite accessible to independent execution, and without the availability of professional construction skills and without the need to purchase additional expensive equipment. The total estimate of the whole project is also reduced due to the fact that additional costs for other insulating materials are excluded.

Disadvantages of warm plaster

When choosing this method of finishing, certainly consider some features of the flaws of warm plaster:

- The mass of the decorated coating exceeds the weight of many thermal insulation materials, therefore, when designing the bearing capacity of the building, correctly calculate the burden on the foundation.

- In most cases, decorative finish is needed over warm plaster.

Types of plaster

Depending on the use of the use, the following types are distinguished:

- for rough finishes;

- for decorative finishing;

- warm plaster for internal work;

- solution for outdoor decoration.

Important! When laying the composition of the solution, be sure to consider this criterion.

Where are warm plasters?

Warm plaster certainly gives a good effect if apply them for:

- thermal insulation facade of the house;

- insulation ceiling overlap;

- floor finish;

- various sealing pores, crevices, cracks, joints overlap in any part of the building construction, regardless of the type of the basic building material;

- additional insulating walls inside or outside the building;

- decorative treatment of the facade at home and indoors;

- insulation window openings and door slopes;

- creating high-quality sound insulation;

- insulation cap;

- processing of sewer and water risers to prevent their freezing and icing in winter.

Methods of preparation of the solution

To prepare the solution for plaster, first of all, select the appropriate method. To do this, check out the most popular options proposed below.

Important! cooking principle for all ways similar and different complexity. The main difference between each embodiment - formulation, exact proportions of ingredients.

Method 1: plaster from natural materials

Mix these ingredients in the specified proportions:

Method 2: A solution for interior

Sequentially add to the vessel and mix the following materials:

- cement grade M400 - 1 part;

- perlite or vermiculite - 4 parts;

- your requirements suitable plasticizer in proportions indicated by the manufacturer, based on the total weight of your or PVA glue - 50 g per 1 bucket of cement;

- water.

Important! Liquid for dilution add so that the resultant solution had a smooth consistency pastopodobnuyu convenient for application.

Method 3: a mixture for the exterior

Prepare all the ingredients measured off the required number of one tool to the exact rules to sustain the formulation:

- cement - Part 1;

- perlite - 3 parts;

- suitable for your requirements ready plasticizer by the manufacturer in the amount indicated in the instructions on the package;

- polystyrene foam, the size of which corresponds to fractions 1-3 mm - 1 part;

- polypropylene fiber - 50 grams;

- water.

Method 4: Preparation of dry plaster mixture from producer

This option is the most simple. To perform the work on this technology, do the following:

- Buy a desired number of packages on the basis of the intended treatment area plaster.

- Prepare the mixing vessel, the volume of which is not less than 50 liters.

- Pour the mixture into the mixing bowl.

- Gradually pour water, stirring a solution with a building mixer.

- Perform this procedure to obtain a homogeneous mixture of the desired consistency.

Important! To determine how much you prepared the plaster, apply a small part on the trowel and turn it out - if the mixture did not fall off, the composition is ready to apply.

Flow material

Calculate the pre-consumption of plaster, based on the intended thickness of the solution of the solution. Standard volumes correspond to the following indicators:

- for a 2.5 cm layer, prepare 10-14 kg / m2;

- for a layer of 5 cm, it will be required from 18 to 25 kg per square meter.

Application technology

Perform the surface processing by plaster as follows:

- Prepare the surface thoroughly cleaned it from previous coatings and dirt.

- For smooth surfaces from silicate brick or monolithic concrete, secure the plaster grid with a dowel.

- Not later than 2 hours after cooking, the mixture is applied to the prepared wall with a manual or machine manner.

- Prepare the solution according to the selected recipe.

Important! Calculate the time of applying plaster in such a way as to use the solution no later than 2 hours after its preparation.

- Moisten the surface.

- Apply the first layer with a sprayer, a trowel or tassels, 2 cm thick.

Important! Choose a suitable tool, taking into account the consistency of the solution:

- Apply the second layer of the desired thickness no earlier than 4 hours so that the previous one managed to dry well.

Important! Note that to obtain a high-quality coating with high technical characteristics, the air temperature should be not lower than 5C, humidity - within 70%, and the thickness of the applied layer is not higher than 2 cm. If the project has a total indicator over 4 cm, make the plastering larger 2 times, but a lesser thickness of each layer.

- After drying the plaster, read and align the surface of the grater.

Video

Review the video instruction on the technology of making a solution for plaster and its application on the walls to imagine the entire amount of work and correctly organize themselves in the process of its execution.

Finish finish

With the completion of the surface processing and checking the quality of the coating, adhere to some important recommendations set out below:

- Before applying decorative coating, check the evenness of the plastered surface with a level.

Important! The maximum deflection indicator on different sections is 3 mm / m2.

- Start painting no earlier than in 2-3 days.

- The maximum strength of the plaster layer is achieved only after 28 days - consider this when you choose a method for decorating.

- Checking the thermal insulation property. Do not earlier than 60 days after complete drying of the solution.

Conclusion

As you have already seen, the process of finishing any surface at home is not difficult. The main conditions for guaranteed high heat insulation and strength is the right choice of the type of solution, it is mixed with the specified prescription proportions and the sequential competent application directly to a specific construction site. In this case, you will not have to continue the need for restoration work after a short period of service, and all the technical specifications of the coating will fully comply with your initially specified requirements.