The bath is one of the traditional places not only for hygiene procedures, but also an excellent relax tool and improving your health. Now the bath is considered more as a place where you can spend time in a circle of family or friends. Ship is one of the most important interior items in the steam room. During his stay in this room, the shop serves as a sun bed or a seat for visitors. That is why it should be not only beautiful, but also comfortable, and most importantly - safe. Buy the finished shop for steam room is currently not difficult, but so that it perfectly corresponded to the size of the steam, it is better to make it alone. For a person who at least once kept the handwheel and the planer, it will not be a problem. About how to make a shop for a bath with your own hands, let's tell further.

Content

- Popular breeds of trees for bath shops do it yourself

- Varieties of benches for baths do it yourself

- The main location of the shops in the bath

- Materials and tools for making bath shops with their own hands

- Features of the manufacture of a portable shop for a bath do it yourself

- Features of the manufacture of a multi-tiered bath for a bath do it yourself

- Tips of specialists in the manufacture of shops for baths do it yourself

- How to make a shop for a bath do it yourself: video

Popular breeds of trees for bath shops do it yourself

There is no natural wood in a steam alternative. The use of synthetic materials in conditions of elevated temperature and humidity is not allowed. When heated, they can distinguish toxic substances that definitely not add health. The tree, in turn, is a natural material that is resistant to temperature and humidity drops. In addition, some wood breeds are distinguished by a pleasant smell and useful for the human body.

The most important property of wood is its low heat capacity due to low density. That is why even at high temperatures in the Finnish steam room (up to + 100 ° C) the surface of the bench will be cool and comfortable.

Tree varieties from which you can make a shop for a sauna, a lot. Each of them has its own unique properties that should be known before the start of work.

Among the classic and inexpensive variants of the material for the manufacture of bath shops for the bath can be distinguished by the following wood:

- Pine. Coniferous rocks are distinguished by the separation of aromatic resins, thanks to which a pleasant and fragrant aroma appears in the sauna. However, too much resin can become a problem, which is why it is better to choose boards with a minimum amount of resin pockets. Pine has low density and with frequent fluctuations in temperature and humidity can crack. The advantage of pine is its low cost.

- Linden. This material has an average density (approximately 500 kg / m 3), which is well affected by its resistance to temperature drops. In the process of heating, Lipa allocates volatile substances for the body. Of the flaws of the linden, you can call the need to process before starting work. Otherwise, Lipa can gain moisture, and then starts to deform and rot.

Often in the manufacture of bath furniture use the boards of exotic woods. Naturally, they are not quite cheap, so not everyone afford:

- Meranti. It is a dense wood that practically does not heat up. Its surface does not contain bitch, large fibers, is absolutely smooth and easily processed. Due to the high density of Meranti, the conditions of high humidity are not terrible.

- Abash. Many builders consider this breed of wood ideal for sauna. It has a porous structure, which allows it not to accumulate inside moisture. Despite its low density, Abash is not heated, always remaining comfortable for a person. The only disadvantage of this wood is its price, as they bring it from Africa.

Varieties of benches for baths do it yourself

Steamroom shops in their design are:

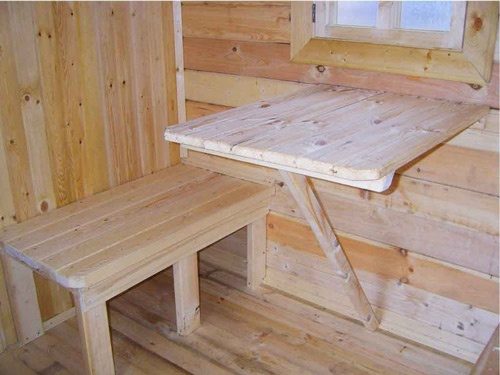

- Single (portable). They are made for small pairs. These are small furniture items that are easy to end out for drying and care. These designs have versatility, they can be used for other purposes, which is very important for cottages and other utility rooms.

- Step. Such shops are made embedded, so they cannot be taken out of the steam room. Used in paired midline. The design of stepped beads, as a rule, consists of two surfaces. The top has a large area, and is designed for lying. The area of \u200b\u200bthe lower shop is small. They are sitting on it and with her climb on the upper shelf.

- Bunk and three-core. Such designs are used in paired large areas. All tiers of such a shop are designed for both lying and for seating, as they have a large surface area.

The main location of the shops in the bath

In order for finding in the steam room comfortable, the bench should be positioned correctly. There are several rules that it is desirable to comply with the adoption of the sauna only pleasure:

- The shops can not be located on the furnace. First, it can cause burns with non-accurant movement, and secondly, too rimmed wood can ignite from high temperature.

- You need to install benches near the deaf wall, where there are no drafts, otherwise you can catch a cold.

- The most optimal location of the shops is a wall opposite the entrance door.

Materials and tools for making bath shops with their own hands

For the manufacture of a bath shop with their own hands, the following materials will be needed:

- Wooden timber - 60x70 mm cross section.

- Rake - a thickness of 20-25 mm and a width of 60 mm.

- Fasteners - nails, screws. Fasteners are required made of stainless steel stamps, as simple self-tapping screws or nails can rust over time.

From the tools you will need:

- Electrolzik, disk saw or, as a last resort, hand-hacksaw on a tree.

- Drill.

- Screwdriver.

- Planked (manual, but better mechanical), grinding.

- Hammer, ruler, roulette, square, pencil.

Features of the manufacture of a portable shop for a bath do it yourself

Portable shop - the simplest design of the sauna shops. A feature of the manufacture of a simple bench without a backrest is its own hands is the simplicity of its manufacture.

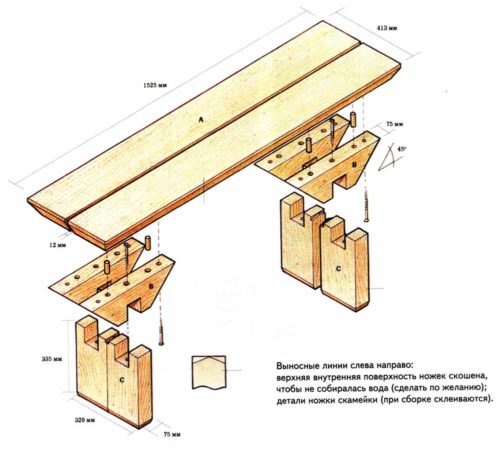

You can make a couple of shops yourself for 1 day. The process of making simple shops Next:

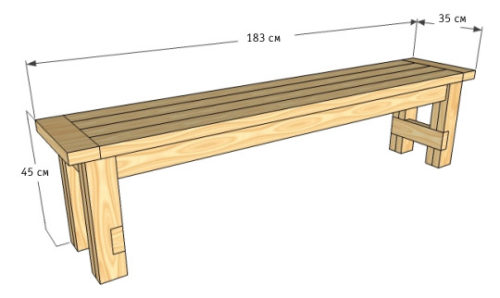

- First of all, it is necessary to prepare surface laying boards. The minimum length of the shop for a comfortable use is 1800 mm. This should be the length of the board. The width of the shop should be at least 500 mm.

- There should be a maximum of 10 mm between the rails. It is necessary to compensate for thermal expansion of the tree and to remove moisture from the surface of the shop. That is, for a width of 500 mm, we will need 7 boards with a width of 60 mm, taking into account the gaps. Boards need to be well treated and polished. It is advisable to take chamfers from the corners. With a bar need to do the same.

- Next, 400 mm long legs are bottled from the bar. 4 crossbars are cut from the same bar. One pair of crossbar with a length of 500 mm and a second pair - 280 mm.

- A pair of legs are connected to the upper crossbar using self-tapping screws, and in the middle combine their inner crossbar to ensure the rigidity of the structure.

- Now that 2 pairs of legs are made, the floorboards are installed on top, which are attached with the help of self-sustales.

- Next is installed a longitudinal timber. They are connected by the lower crossbars of each pair of legs. It will give a stability bench and will not give the knife to disperse under the weight of a person.

- When the boards are screwed down the flooring of the shops in them, it is necessary to do sweat to drown the screws of the screws. When the shop will be ready, the holes with the heads of the screws are shaky. You can mount the flooring of the flooring onto wooden brazening, having previously licked up with the last joinery glue.

Features of the manufacture of a multi-tiered bath for a bath do it yourself

Multi-tiered shops are embedded. The frame for them is fixed to the walls of the steam room, and then trim his board.

- For the manufacture of the frame, the bar is needed 60 x 60 mm. It is made of large and small P-shaped framework designs. The height of small will be equal to the height of 1 stage (approximately 50 cm), the height is large - by 70 cm above.

- The designs are connected to each other with fasteners. Their quantity depends on the length of the shop. It is necessary to install them with an interval of no more than 70 cm. That is, for a 2.1 meter meter long, they need to at least 5.

- All of them must be securely attached to the walls of the steam room using a dowel. Extremely attached to the side and back wall, medium - only to the rear. All designs are securely attached to the floor.

- When installing structures, the correctness is verified using a level.

- Now the frame can be sewed. First, horizontal surfaces are trimmed, then vertical - between two steps.

Tips of specialists in the manufacture of shops for baths do it yourself

- Before use, the tree needs to be processed well: to span the surface, round the edges. Otherwise, injuries when using the pair will not be avoided.

- It is unacceptable to use benches and paints to cover the tree. When heated, they can highlight toxic substances that may cause poisoning.

- When using coniferous wood, it is necessary to verify the absence of resin pockets. When heated, they can highlight a resin that can be simply burning.

- For connecting parts, it is better to use the drums. If self-tapping screws or other metal products are used, they must be safely hidden in order not to burn them about them.

- Between the lower bench and the floor should be a gap. Otherwise, the moisture will accumulate under it, which will lead to the rotting of the tree.

- After using the steam room, it is necessary to ensure its normal ventilation. This will be the key to the long service of bath shops.