Flexible materials based on bitumen and fiberglass are used for the roofing device of residential buildings, household buildings, garages. There are rolled and piece coatings whose popularity is explained by simplicity of laying, relatively low cost, high waterproofing characteristics. With proper laying, the service life of such a coating can be long. But still during operation it is necessary to repair or the current elimination of soft roof defects with their own hands. About repair technology will go further.

Content

Types of soft roof defects

To prevent problems related to the roof leakage, it is necessary to regularly examine its surface for the availability of defects. Such may be:

- local blown;

- the growth of moss in folds and deepening;

- detachment in the field of alternate rows of cloths and plates;

- cracks and ruptures.

The causes of soft roof defects are its contacts with branches next to growing trees, attachments of antennas, stretch marks and with ice. Negative impact has a strong wind.

The examination of the roof state should be made in spring, after the snow and fall, before the start of the rain and cold season. It is necessary to remove the branches, the construction trash and other items from the roof. When damage is detected, repair should be repaired.

Types of repair of roofing

Features of the repair work with a soft roof with their own hands consist in determining their scale and method of execution. Depending on the damage, one of the following types of repair is carried out.

- Current: During the work, the butt compounds restore, eliminate cracks and other small defects.

- Capital: It is necessary when the current repairs are not enough to seal the roof.

- Emergency: Performed with random damage to the roof covering, which causes the leakage.

Current repairs of the breakdown or crack provides for the following.

- The zone of damage is cleaned of garbage.

- Bituminous mastic is applied to the crack or gap.

- The required size piece of rubberoid is superimposed.

- Another layer of bitumen is applied.

Damaged joints are restored as: the edge of the coating is wrapped aside, after which the gas burner is dried by a plot on which the material must be glued again. Apply a bitumen and tightly pressed the coating. For reliability over the joint, the bitumen is re-applied.

The features of the overhaul of a soft roof with their own hands can be represented schematically:

- a complete dismantling of the old coating is performed;

- crowing the ceiling slab is cleared and restored;

- stacked a layer of vapor and waterproofing;

- a new bituminous coating will be filmed.

To reveal the roofs on the roof, where rainwater can be gathered, you need to pour the roof of water and circle the recess marker around the perimeter. After that, the water is cleaned with a rapid, the screed is dried with a gas burner and a bitumen material is superimposed on the marked areas.

Tools and materials for roof repair

Before starting work, you need to purchase the necessary tools for repairing a soft roof. Next:

- gas burner or soldering lamp (the first option is preferable: the burner is longer and more stable);

- the ax, a large spatula or other suitable tool for cleaning the roof from an old bituminous coating;

- construction knife;

- quakes from the vehicle - to treat the roof of bituminous mastic;

- broom for cleaning from garbage.

If you need to perform emergency repair in winter it will take a wooden or plastic shovel for snow cleaning.

Important: All work should be performed in workwear and protective glasses. It is necessary to suit the welder of dense tarpaulin fabric, shoes and mittens.

Types of soft materials for roof repair

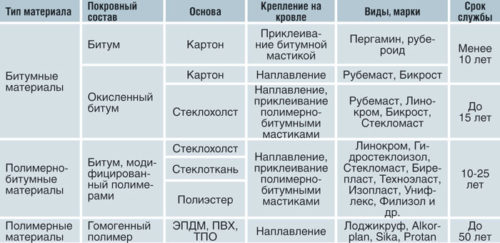

Conditionally bituminous roofing materials are divided into categories:

- waterproofing;

- lining;

- roofing.

For roof repair, the following types of flexible materials indicated above are most often used.

- Parchment: Dense cardboard impregnated with bitumen composition. Used as an additional waterproofing material.

- Cardboard: Lining material stacked in front of waterproofing coatings.

- Tol. It happens two types: with finely abrasive mineral sprinkling and without it. It is a dense cardboard with impregnation based on tar. Used as a waterproofing material.

- Ruberoid (as well as its modern counterparts): Cardboard with oil bitumen or fiberglass material. The impregnation is two-layer. From above - sprinkle from coarse basalt crumb or talc chips to protect against sunlight.

- Bituminous tile. It is based on fiberglass, impregnated with tar and bitumen. From mechanical damage protects the sprinkle from the mineral crumb.

Depending on the method of installation, bitumen roofing materials are divided into the following types.

- Rolled: Apply only complete with an adhesive mass on a bitumen basis. The glue is applied to the back of the rubberoid, after which the material is rolled along the roof. Thus, you can completely restore the coating.

- Claimed: The back of such materials is the adhesive composition. During installation, it is necessary to put the material with adhesive base on the roof and warm up the gas burner.

- Mastic: distinguish between the use of cold and after heating. After applying, the place of damage is harvested and securely seal. Can be used as glue for rolled materials.

Tip: As roofing materials, a linocur, isoelast, uniflex and linocur (serve at least 10 years), for waterproofing - technolast, glass elast, Brepelast (elastic materials).

How to calculate future roof repair costs

In the estimate of the planned repair, such factors contribute:

- type of repair (current or capital);

- the area of \u200b\u200bthe roof that needs to be repaired;

- roof configuration (length of cornice sills, presence of adjoins, etc.);

- degree of damage to the surface of the roof;

- the number and cost of materials for repair;

- the amount of preparatory work;

- payment of work team of specialists.

You can save on the latter if all work is done yourself.

Blood Repair Technology

To any repair of the roof, regardless of the volume, should be prepared. For this:

- choose the time when it is not expected rainy weather;

- from the surface of the roof, garbage and foreign objects are cleaned, lift and tied up cables;

- purchase the necessary tool and fixtures.

Local roof repair: phased description

In the event that the overall condition of the roof is good, but there are single small damage to the cover, the repair is performed according to the following technology.

- The coating in the damage zone is caught crosswise and wrapped triangular fragments to the side.

- Place of repair is purged by a construction hairdryer for cleaning from dust and drying.

- The open area is poured with mastic, completely filling it.

- Pre-prepared in the form of a section of repair fragment of the rubberoid is stacked and pressed.

- On top of the patchwork poured mastic.

- Fragments wrapped on the sides of the triangular shape are stacked in place and pressed.

- Obill the square shape of a rubberoid piece.

- Place of repair is poured by bitumen.

Large damage is eliminated by another technology.

Stages of overhaul of soft roof with their own hands

If damage to the roofing coating is numerous and distributed over the entire roof area, overhaul is needed. In this case, the following is performed.

- It is not recommended to repair on top of the old coating. With your own hands with the help of an ax and other suitable tools, it needs to be completely removed. The base of the root must be given to dry.

- Screed (base of flat roof) is repaired: chips and cracks are processed by primer and then cement-sandy solution. The waterproofing subtenitory material is stacked.

- The frozen tie is covered with bitumen. Distribute bitumen evenly with the help of a mop and anger from the vet.

- Ruberoid rolls away and leaves for a while: the roll material should be aligned. After that, the material is again rolled into rolls for the convenience of transportation.

- Rolls are cut down the length of the roof. Canvases are laid on the roof with an overlap at least 0.1 m. The edges are carefully cooked by bitumen.

- Rolls are rapped simultaneously with the heating surface of the roof and the back side of the rubberoid with the help of a gas burner. To roll the roll, use a metal coocher with a long handle.

- In places of formation of bloats, it is necessary to release the accumulated air. For this, the rubberoid is pierced, pressed to the roof, and the place of puncture is poured by bitumen.

Important: To create a hermetic and reliable coating, you need to lay from two to five layers of rubberoid. Each new layer should cool at least 12 hours before mounting the following.

Tips for choosing Mastics for roof repair

The elasticity, integrity and tightness of the soft roofing coating is achieved through the use of polymer bitumen mastic. It happens two types:

- cold use - with it, it is placed rubberoid to repair internal roofing layers;

- hot use - ready to work becomes after heating by a soldering lamp or gas burner (with its help, the outer materials are mounted).

Bituminous mastic can be made independently. For this, two parts of the bitumen mixed with one part of the filler (lime, ash or plaster) and dissolves in two parts of the gasoline. Technology process is as follows.

- Before mixing components from bitumen, water is evaporated by heating up to 180 ° C (the sign of this is the cessation of the formation of air bubbles). After that, the bitumen must cool.

- The bitumen is heated again to 200 ° C, after which the filler is gradually added to it. In this case, the temperature of the mixture needs to be monitored: it should not fall below 160 ° C.

- The heated components of bitumen are periodically mixed during the preparation of bitumen.

You need to use the finished mixture immediately, it cannot be stored for a long time.

Important: In the process of preparation, the mixture cannot be poured gasoline in bitumen. It is safe to add bitumen to gasoline.

Replacing the shingles of bituminous tiles do it yourself

Repair of the roof of soft tiles is reduced to identifying and replacing damaged shots. It does not need to dismantle a horizontal or vertical range of coating. Algorithm of repair Next.

- A small hatch carefully tear the edges of the adjacent tiles from the bottom to the left and right.

- Returning to the fastening nail, we remove it ticks and a nail.

- The new gear from the back side is covered with bitumen mastic. The amount of mastic must comply with the requirements of the coating manufacturer.

- We put a new shingle to the place of the damaged element.

- Holding the edge of the upper gear, drive a new nail into a new tile. It should be shifted a little away from the previous place in which there was an old nail.

- The bending edges of the adjacent tiles are lubricated with bitumen mastics and tightly pressed into their place.

Note: The roof covered with bitumen tiles with an angle of a slope, insufficient to ensure the normal flow of melt and rainwater, will flow, even if all gents are integer. In this case, you need to change the type of coating.

Repair roofing penetration with their own hands

The outlets of the antennas, ventilation channels and chimneys are the problem of the roof. The direction of bitumen and scoring of rubberoid does not provide tightness.

Prevent leakage in such zones can be provided in the following ways.

- Installation of peaks from galvanized steel sheet. Sheet thickness should be at least 1 mm. Such an element is attached to the pitched roof so that the rubberoid closes the upper part of it. On the flat roof the runner should be directed to the vertical part of the penetration of at least 0.1 m.

- Installation of penetration of a special form from elastic silicone. Such material is withstanding the temperature to +260 ° C. Silicone penetrations are easily installed and firmly adjacent to the roof. Their service life is long.

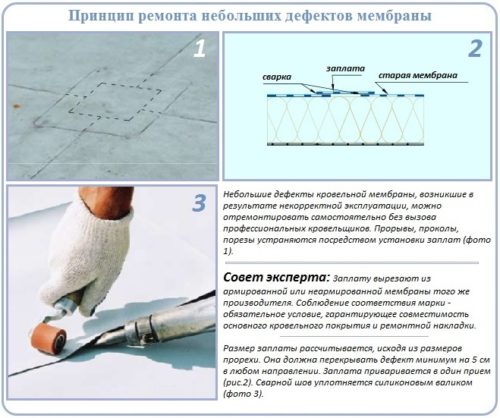

Repair of membrane roofs do it yourself

Roofing membrane is a film material. The term of its service is at least 30 years. In the case of local mechanical damage, one of two repair methods are used.

- The wolk is superimposed, in advance carved in the size of a damaged area. Printing is carried out using a hot air generator - a construction dryer.

- A small crack close up without a margin: the dryer is heated by the damage zone, as a result of which the edges of the crack will again be connected.

If the membrane coating is damaged to a more large extent, repair requires the use of other technologies.

- Without dismantling old membrane coating. The roof is cleaned and covered with primer. Stay new roofing material, welding adjacent canvas.

- The coating that came into disrete was dismantled, the base of the roof is cleared and, after complete drying, is stacked with a layer of waterproofing material on top of the primer. Reliable waterproofing can be created using several coating layers.

Recommendations for repair and maintenance of the roof

In order for repair to be performed qualitatively, the following rules must be performed.

- Plots of roofs protruding over the general level, you need to close the solid web. To block half of the canvas or marked fragments is incorrect: after a while, the moisture will penetrate under the coating.

- Removing the snow should be left thin layer on the roof: he will be able to protect the coating from the wind.

- Clean the roof from snow and garbage can only be wooden or plastic shovel and broom. A rough tool can damage the roof material.

In the conclusion of the article on how to perform the repair of a soft roof with their own hands - video with comments of the process details.