Since the invention and still brick remains one of the most popular building materials. It is used literally for all - the construction of buildings, facing, construction of furnaces, laying tracks, etc. There is a lot of brick species, and each of them is intended for a particular construction industry. Thus, large porous blocks are lightweight and well kept warm, so ideal for creating cozy houses, thin clinker tiles are good for finishing, and to build a furnace, a fireplace or chimney use refractory chamotte bricks. Only this type of material is able to withstand high temperatures and ensure the necessary strength of the structure. This article is devoted to the characteristics and features of the use of chamotte brick.

Content

Manufacturing technology

Among all the varieties of bricks, chamoten is the most durable and resistant to strong heating and temperature differences. By these qualities, the material is obliged to its composition and specific manufacturing technology consisting in the firing of the clay mixture with the addition of chamotte powder. As a result of the impact of high temperature, the brick acquires a characteristic gray-brown or yellowish color, according to which it is easy to distinguish from the rest of the varieties.

The composition of chamotte brick determines its operational characteristics. Depending on the proportions of clay and powder distinguish several varieties of material. A colossal role is played by the processing method, or rather, the baking time of bricks. So, if you redo it in the furnace, then a durable vitreous film is formed on the surface, which will make the brick incredibly durable, but less refractory. If it is not enough to burn it for a long time, then such a material will be well absorbing and retaining moisture, but completely loses its strength. Only if you stick to the "Golden Mid", you can make a brick, perfect for laying furnaces and fireplaces.

So that the product does not crack in the roasting process, they add a certain amount of special refractory clay - chamot. Sometimes a coke powder, graphite or coke-grade quartz are put instead. As a result, various types of bricks with individual characteristics are obtained. Moreover, the result depends not only on raw materials and processing method, but also on the characteristics of fuel for firing and the resulting ash.

The production of chamotte brick is carried out in accordance with GOST 390-69, and depending on what it will be used, the production, weight and size of the material differs. So, the mass of chammed brick can vary from 2.5 kg to 6 kg. Differences are also in density, porosity and composition of bricks. There are uniform sizes that most manufacturers adheres to: 230x113x65 mm, 250x123x65 mm and 300x150x65. These are the most convenient dimensions for construction and transportation.

The most commonly used chamotte brick stamps: SB No. 5, SB №9, SB No. 22, SB No. 44, SB No. 47. The letters facing the number can be different, for example, PB, SB, ACUS, CHL and others, but for household use it is better to choose bricks with a note "SB". The first letter suggests that the brick chammatory, the second means to which class of fireproof it refers, and the figure is the aspect ratio.

Lightweight brick

Light chammed brick has proven itself as a good insulation. It consists of peat, fatty clay, sawdust and other components of organic origin. In the process of firing, they burn out, leaving behind the pores of various sizes. This manufacturing technology allows you to get a very light porous material with high energy efficient characteristics.

Since lightweight bricks are made entirely of the organic matter, they are an environmentally friendly material that does not harm human health or the environment. At the same time, high refractory is preserved - the brick can withstand an extremely high temperature to 1800 ° C.

In the form of lightweight bricks can be rectangular or wedge-shaped. In order for the material to fully retain all its operational properties, it must have a correct structure with even edges and completely straight corners.

There are several varieties of lightweight bricks depending on the scope of application:

- trapezoidal;

- shaped;

- straight;

- rib Wedge;

- facial wedge.

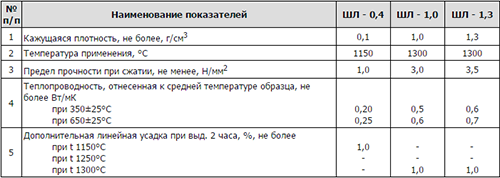

The labeling of the lightweight brick is indicated by the letters of CHL and PCL (T - presence in the composition of the talc). It is usually used to create a heat insulating layer during the construction of electric furnaces, heaters, evaporator units, steam pipelines, heat exchange boilers, etc. Such protection can significantly reduce heat loss by 20-70%, reduce the mass of thermal devices and their dimensions. If you buy a chamotte brick for building or facing the oven, the time of heating and cooling will be reduced 5 times, and fuel costs will decrease by 10% in continuously working furnaces and by as much as 45% in periodically working.

Characteristics of bricks

One of the main characteristics of chamotone brick, in addition to resistance to high temperatures, is immunity to the effects of aggressive acids and alkalis. That is why the main sphere of its application is metallurgy, frying porcelain, glass production and various chemical compartments. Ordinary clay bricks are not able to withstand such extreme conditions, and the shape calmly copes with heating to 1400 ° C or even higher.

By the way, precisely because of this ability to withstand high temperatures, chamotte brick cannot be used together with other materials, for example, a conventional denied or silicate brick. A strong difference in operational characteristics will sooner or later lead to the destruction of the constructed object.

However, permissible combination of various varieties of refractory bricks:

- Quartz - the composition of raw materials includes coarse quartz. Such bricks can be used in cases where the walls of the furnace are in contact with open fire or metal. In contrast to chamotte brick, they are not able to withstand the effects of chemicals and alkalis. From quartz bricks build crops of reflective furnaces. It has a dense homogeneous structure, and after the firing acquires quality similar in nature with natural sandstones.

- The main (from the word "base") is a burnt lime-magnesiac mass. Such bricks are actively used in the metallurgical industry for the processing of phosphorous ore and receiving non-workers.

- Carbonistic - this type of refractory brick is used only in highly specialized areas. If briefly, it is highly pressed coke or graphite, which is used for the facing and construction of blast furnaces and other structures with extremely high temperatures.

Advantages and disadvantages

The main advantage of the chamot, determining its niche in the construction market, is the ability to withstand extremely high temperatures and remain warm for a long time. That is why such bricks are ideal for the construction of furnaces, fireplaces, chimneys, mangals, etc.

It is nice that the furnace chamotte brick is not only effective, but also pretty beautiful. An unusual mustard shade instantly creates a feeling of comfort and comfort. The furnace or fireplace from this material is capable of setting the interior style of the whole house. With the help of elements of non-standard forms, you can create interesting compositions and unusual geometric forms. For example, for arches and arches produce special wedge-shaped bricks, there are also trapezoidal, classic rectangular and other forms.

Among the advantages you can also select the size of the blocks - they are much more standard clay bricks, so for the construction of the chamot will need less. For stacking furnaces and fireplaces, they are mainly bricks with marking SB No. 5 and SB No. 8.

The weight of chamotte brick is much smaller than the usual clay, which significantly reduces the load on the foundation for the furnace. And since the laying is carried out on a thin layer of the adhesive solution, it also helps to reduce the weight of the whole building. By the way, the conventional cement-sandy solution is not suitable for bonding, since it will not withstand strong heating. In this case, it is necessary to use a special temperature mixture.

Despite the large number of advantages, chamoten brick has a number of nuances that can rather be regarded as features of use, and not flaws. So, he strongly absorbs moisture, as a result of which its strength is reduced and the mass increases. Such hygroscopicity does not allow it to apply it in rooms with high humidity, for example, in a bath.

If the furnace, built of chamotte brick, heat irregularly or give it completely cool, then over time it will begin to crumble. Such instability to the freezing imposes a number of requirements for the operation of such structures.

Because of the high density with chamoten brick, it is quite difficult to work - cut it with a hacksaw, like a gasoblock, for example, will not work. To do this, use a grinder with a segment diamond disk or bakelite disks for stone.

The price of chamotte brick is quite high compared to the usual, but due to larger sizes it will be needed. A small weight will save on transportation and foundation. In some cases, the construction of an object from the chamot is more profitable than from other materials.

Specificity of work with the material

As already mentioned, refractory bricks are used for the construction of furnaces, fireplaces, firebox facing, etc. It is actively used in industrial installations, whose combustion products are saturated with aggressive chemicals - domain cameras, fuel boilers, etc.

Naturally, not every solution is able to withstand such conditions, so it is better to refuse to immediately immediately refuse. The composition for laying chamotte bricks includes the same components that are part of the refractory material. For example, to work with bricks, SB-5 and SB-8 use refractory clay with an admixture of chopped bricks. As a result, the so-called chamotte clay is obtained - the measureer.

Important: Depending on the maximum temperature, which will be maintained in the design, the thickness of the masonry layer varies. The stronger the heat will be, the thinner the layer of the solution. Its thickness in some cases can be only 1 mm, so it is very important that the composition has a maximum setability and a strength.

Brick manufacturers

When buying chamotte bricks, it is necessary not only to deal with the labeling and characteristics of the material, but also pay attention to the manufacturer. It must be a firm with a perennial experience and good reputation. In the modern construction market there are several large manufacturers offering high-quality refractory material.

Large manufacturers of chamotte brick:

- Kondratyevsky refractory plant is a Ukrainian plant equipped with modern standards and producing high-quality world-class raw materials. It is engaged in the manufacture of refractory bricks, mullite-coordinated saiberboards for casting steel, aluminosilicate products, etc.

- LLC OGNAUPOR - the Russian manufacturer, known since the beginning of the 30s of the last century. Making chamotte products began to engage in 1965 and is still one of the leaders in this sector.

- The heat program is a scientific and manufacturing enterprise that carries out the wholesale sale of refractory bricks in Moscow and other regions of Russia.

- The watchman is another Ukrainian manufacturer, which has more than 100 years old.

- TD "ROSOGNEUPOR" - an enterprise located near the Latnensky clay deposit. The plant was built in the 30th year of the last century, for its history there was a lot of changes and today is equipped with modern equipment for the production of chamotte products.

Only refractory chamotte brick is suitable in the furnace! http://pcfdelta.ru/galery/