It is beautiful, practical, durable - so you can characterize the roof of shale tiles, which will last up to 200 years, without losing its excellent qualities. The proof of these statements serve as a photo of which is replete with an article and video installation of a shale roof. Characteristics and advantages of such a roof, methods for its installation and installation rules, for which roofs it is suitable, as well as information about the value of this type of roofing, you will find in the article.

Content

In the days of the feudal reign of shale roofs covered the roofs of castles and fortresses. Now she is at the peak of popularity. Not in vain say that all new is well forgotten old, so about the shale roof for a period of time almost forgot: it was used to cover the roofs of buildings quite rarely and, mostly in Western Europe. But the excellent characteristics of this building material allowed him to practically return the palm of the championship among roofing covers not only in the West, but also in our country.

Characteristics, advantages and disadvantages of shale roof

Slate is a layered breed, which can reach 400 million years. The remains of the collapsing rocks, settled on the seabed, for many years forming fine-grained deposits. Under the influence of the upper reservoirs, the lower fits were compacted and crystallized, then the splitting of rock and layering of the formation. The thickness of shale deposits reaches several kilometers, and the thickness of each layer is from 1 to 8 mm. The layers are easily separated, which makes it possible to produce shale roof with various parameters.

Specifications

- Service life without loss of properties is 200 years.

- Standard thickness of produced tiles from 4 to 9 mm.

- Tiles make both squares with sizes from 20 cm and rectangular.

- The weight of the coating on 1 m² can be from 25 to 50 kg (with double laying).

- In order to use shale roof as a roof cover, its slope should be from 22º. The more degree of slope, the smaller the size of the tile must be used.

- High bend strength, reaching 61 MPa.

Advantages and disadvantages

As a high-quality natural roofing material, shale roof has a lot of advantages over other materials of this purpose:

- environmental friendliness;

- preservation of color, structures and characteristics throughout the service life;

- excellent strength and density;

- the possibility of operation, both at high and at low temperatures;

- insensitivity to sharp fluctuations in temperatures, the absence of deformations;

- lack of corrosive processes;

- low water absorption;

- excellent sound insulation;

- The possibility of laying on the roofs of any configuration.

With all the benefits of such a roof, it also has a number of disadvantages that need to be considered if you decide to perform the roof of the building from a natural slate:

- shale roof has a high cost due to the use of manual labor in production and high costs during raw materials;

- the price of laying shale roof is high enough due to the complexity and complexity of the process;

- small number of highly qualified experienced specialists in laying this type of roof;

- the need for an additional enhancement of roof structures due to the large weight of the material.

Methods of laying

There are three types of laying of shale roof: French, German and English.

French

In this way, the square tiles are placed, the side angles of which are bevelled. Fasteners tiles to the crate is made by nails. From a leeward side on the rod of the roof for sealing the tile joint, it is placed in 2 rows, making the angle with a solution formed due to different heights with the tiles of another skate.

German

Applied quadrangular tiles whose angles are rounded. The limit of the roof for this type of laying should be 25º. The masonry is laying upward rows at an angle, which must define the wizard, and nourishes three nails to the crate. There is a covering of the lower rows tiles of the upper.

English

This method is used with double laying of rectangular shale tiles on the roof with an extreme angle of slope 22º. Laying is carried out by horizontal rows. The magnitude of the intake and lateral gap (30-60 mm) defines the master. Fasteners can be made both nails and special types of hooks.

Installation of shale roof

If the laying of the tiles from the slate will be made correctly, in compliance with all the rules of installation, then such a roof will not require repair and investments in the next 200 years. But an experienced high-class specialist should perform the installation of such a roof.

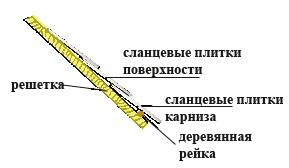

- Wooden guide design should be strong, cross sections 40-60 mm, the distance between them should be less than ½ the length of the tile. In areas where strong winds and high humidity, a solid formwork is performed, which is covered with parchment.

- Bringing tiles to the crate is produced by 2-3 copper (galvanized) nails with wide hats. Between the nail and tiled cap, be sure to leave a small gap to protect the material from cracks in case of deformation of the crate.

- Material starts to lay from the drain, where large-sized tiles are used, smaller tiles are used above.

- Fall tiles when laying is 60-90 mm. The smaller the bias of the roof, the greater the backstage.

- Laying the roof of shale tile is the final stage of all types of work on the roof.

- When choosing the direction of laying, it is necessary to take into account the direction of the current winds in this area.

- Before laying the tiles, each of them should be sprinkled with a hammer to determine the presence or absence of cracks. If the sound is deaf, then there are cracks on the tile, and it is impossible to use such a tile.

- Tiles laying lines should be smooth.

If you doubt, use a slate or cover the roof of another material, read reviews about shale roof on the Internet, and your doubts will disappear. No material is so durable and resistant to external influences, like slate tiles. Your roof will be not only high quality and strong, but also beautiful all the time of operation.