Books use a two-circuit content of bees to increase the productivity of the beekeepers, but with the help of this technology, the increase is reduced, as well as facilitated the task of training nests to wintering. The hives, different and two-circuits too, are on sale, but we will look at how to make a two-minded hive yourself.

Content

What rules should be bee housing

There are queries that are common to the hives of all without exception. It:

- Dryness

- Possession of the ability to keep warm in winter

- Excellent ventilability

- Compliance with the optimal volume

- Ease, convenience, durability

- The presence of drafts in places where the parts are unacceptable are connected.

Requirements for construction

What kind of design was not a hive, the following values \u200b\u200bshould remain unchanged:

- The interval of the wall-side bar frames is 0.75-0.8 cm;

- Frame thickness - 2.5 cm;

- The inter-center distance between the framework located nearby is 3.7-3.8 cm.

Wooden Material

For the manufacture of housing for bees, the following types of trees are used:

- spruce;

- non-massive pine;

- fir;

- cedar;

- lipa;

- osin.

Tree requirements:

- maximum moisture content of wood - 15%;

- if there are holes formed in the board in the board, inserts for their sealing.

Healthy: purchase wood boards, harvested and sawn in winter. She is more resistant to rotting. Summer timber must need to dry well in a special dryer since it is very juicy.

What is the collected two-circuit hive

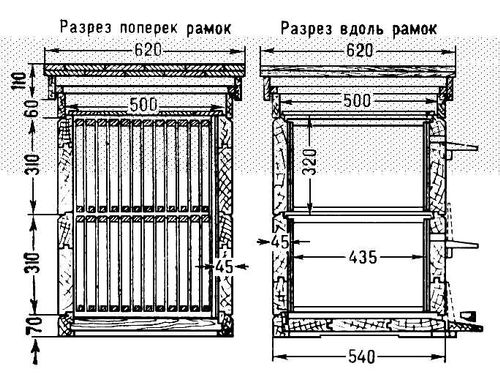

Two-circuit hive, accommodates 24 frames. His drawing that you see below is composed of the following items:

- roofs flat -1. It is designed to protect the hive from precipitation. Roof sidewalls have slits or round holes to ensure ventilation;

- ceiling powder - 2;

- pierce - 3. It places the upper insulation and fix the ceiling reduction;

- the nesting frames are mainly housing and in the superstructure - 4, 8. This is a place where the bees arrange nesting cells.

- the diaphragms or plug-in boards in both housings - 5, 9. limit the volume of the nest, focusing on the strength of the family. If necessary, the insulation can be placed behind inserted boards;

- upper case - 6. It is a box, shot down from the boards. The inside of the housing has dimensions of 45.0 x 45.0 x 31.0 cm;

- two arriving boards of the upper pilot - 7, 11;

- lower case - 10;

- dNA - 12. May be capital or removable. It includes a shield and a strapping. Has a ledge for attaching a flying board;

- adilet board at the lower flyer - 13. At the same time, the take-off and landing band for bees. When transporting bees and during preparation for wintering it is dismantled;

- pilot Cups - 14.

In two identical buildings of a typical one-sided 2-housing hive, 12 frames are located. The sizes of the frame - 43.5 x 30.0 cm. The parameters of two-circuit hives are shown in the drawing:

Advantages and disadvantages

Advantages in two-circuit hiles Many:

- the conditions of content stimulate good egg production, so in bee families there is more intense the process of a breakdown;

- bee families are less likely;

- almost half, or rather percent of 45 percent, productivity increases;

- prepare such bee families to wintering easier;

- the wax exit rate is growing;

- bees living in two-circular ulle, strong, possess good heredity.

It is impossible not to say about the shortcomings of the content of bees in two-circuit hives, and rather - about the lack, because He is probably one:

- large weight: about 45 kg together with the frames that have to be released from honey, because Rearrange the superstructure when pumping honey, you will often have, then it is hard, of course.

Getting to manufacture

We start collecting everything you need to build a hive.

Material

To make 1 two-circuit hive takes:

- board - 0.209 cubic meters. m. The calculation was made in recalculation on the round log. This number includes boards with thickness:

- 40 mm - 0.075 cubic meters. m;

- 25-35 mm - 0.038 cubic meters. m;

- 19-22 mm - 0.029 cubic meters. m;

- Bar 5-7 cm - 0.002 m cubic meters.

- nails - 0.35 kg;

- screws - 0.052 kg;

- round washers - 0.008 kg;

- brackets - 2 pcs;

- galvanized mesh with a cell size of 0.3 cm - 0.12 sq. M. m;

- roofing steel galvanized - 1.95 kg;

- supplements for arriving boards in the form of lining - 2 pcs.;

- olife - 0.5 kg;

- grated paints - 0.04 kg;

- zinc grated bleached - 0.3 kg;

- ground chalk - 0.4 kg;

- casein glue;

- 2 linings for arriving board.

Tools and equipment

Good to have the following equipment and tool in the economic:

- cutting machine or hacksaw;

- planing machine;

- mill;

- clamp;

- chisel or chisel;

- pleismus.

Cases. 1st version

- cut the billet from a 40 mm board on a sawing machine or with a hacksaw:

- For the front wall - 53 x 29 x 4 cm;

- For the rear wall - 53 x 37 x 4 cm;

- For sides - 48 x 37 x 4 cm.

- align the surface of the board on a planer machine;

- in the walls of the top of the housing, we perform false grounds. Size - 1.1 x 2 cm;

- in the same part, we make False 1 x1.4 cm for the possibility of installing the 2nd floor;

- in the walls that will be located in front and rear, select the end folds (quarter). This will ensure strength, stability and eliminate the appearance of through slots in the case. Their dimensions:

- Width 4.0 cm;

- Depth - 2.0 cm.

- in the front wall of the 2nd case, retreating from the top 7 cm, we perform a hole with a diameter of 2.5 cm. It will be a pilot;

- i drag the sleeve of a round cross section, which will climb the flyer;

- we fasten with each other of the board, from which the walls of the housing in the ridge and the shunt are consisting. At the same time: the shunt has a width of 1.5 cm and a depth of 1-1.5 cm. Between the bottom and the facade wall, the clearance of 1.5 cm should be formed. It will be a pilot. Two valves regulate its dimensions;

- we connect the end ends of the housing walls at the corners of the nails with a diameter of 0.3-0.35 cm and a length of 8-10 cm.

Option number 2: How to make a double-circuit hive with shopping bags

The second body of the two-circuit hive can be made not an exact copy of the first, but in the form of two stores that have:

- dimensions in length and width similar to the case;

- the height of the side walls - 16.5 cm, thickness - 3.0 cm;

- the dimensions of the front and rear walls are the same as in the side, but the thickness of them is 4.0 cm.

Production rules repeat the ones that we followed, manufacturing two-circuit hive in the first option. Good to know: For the manufacture of the walls of the case, it is better to take the boards of different widths. If the board with a greater width in the side walls is located below, then manufacturing the front and rear walls, place such a board at the top - the bonding of the adjacent walls will be more durable. Well, the case is ready, go on.

Roof for a bee palace

The roof includes:

- binding;

- roofing shield.

We work in such a sequence:

- we take a 2 cm thick boards and perform 150 millimeter widths of the strapping, for which 45 x 45 cm blanks will be needed;

- to give the roof a steady position, you feed the planks around the strapping;

- ventilation is needed, therefore, on the sides in the strapping, the holes with a diameter of a maximum of 2 cm are drilled, and so that the bees do not accept them for the letters, close them or something with something else;

- we close the strapping on top of the boards;

- enhance the roof of galvanized iron sheet.

Pierce

Design is extremely simple:

- walls: ahead and rear;

- sidewalls.

This technology is:

- first, cut out the billet from 25-mm board of the same sizes;

- processing boards on the machine: planing and tertsy;

- to connect the walls, perform direct spikes 2 x 2 x 2 cm, pre-placing them;

- glue the workpiece using casein glue;

- we succeed;

- additionally, we strengthen the hairpins from the tree.

Important: at cutting spikes, it takes great accuracy, so the blanks first temporarily connect nails, and then place and drink.

Ceiling

It consists of a ceiling of duffle, while:

- they should lie between the walls freely, for which we do their shorter than this distance of the centimeter on one and a half;

- we process skimming for the ceiling on a planer machine;

- we put them not tightly so that the bees wanted to postpone propolis there.

Bottom

It is better if this detail of the hive is removable. So:

- drinks on the blanks of the bars with a thickness of 3.5 cm. All of them will need 3 pcs. Sizes of the bottom 54 x 48 cm;

- recovering the top of the bar 2 cm make the grooves on a width of 3.5 cm and deepening 1 cm;

- we connect them to P-figuratively in the thorn, additionally fastened, as in the case of a jerfulness, studs;

- insert the floor to the grooves;

- if you look at the hive in front, then the bottom should perform by 3.5 cm;

- in the floor we make a hole for ventilation of 20 x 20 cm and tighten it with a grid;

- now we do, as it seems more convenient for us: whether nails are nailing the bottom to the body, or simply substitute it without securing.

Sillar

- the pilot is a hole through which the inhabitants fall into the hive and leave it;

- located on the front wall, it has a height of 1 cm and the minimum length of 20 cm.

Perform it like this:

- drills 0.8 cm openings along the length of the alleged pilot;

- walls between holes remove;

- we make a pillar insert, with which we will adjust the pillar clearance. In the cold it will be smaller, and in the summer the liner is removed at all.

Board arrive

- it is installed flush with the lower edge of the flyer with a small outer inclination;

- has sizes:

- length is a little more than a pilot;

- width 10-15 cm.

Depending on how power the bee family has, adjust the dimensions of the socket. For this and need

Diaphragm

Dimensions: a shield - 45 x 32 x 1.4 cm; Upper timber - 47.2 x 2 cm, with which the plug-in board hangs on the wall. May be useful: the diaphragm is made from the usual frame if you close one side with the hands and put the insulation on them, and so that it does not fall out, to kill burlap.

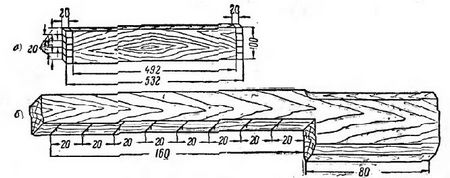

We make framework

Frame that nesting that the shop consists of:

- the top bar who has shoulders;

- bar of the bottom;

- side slats.

The sizes of the semi-frame are the same, but they are already about 15 cm. Production process:

- cut wide blanks;

- we proceed on both sides on the rigal machine;

- we make upper bars, while the lateral stop of the sawing machine is set by 2.5 cm;

- we dissolve the workpiece, getting two bar 25 mm;

- the focus is transferred by 0.5 cm and cut off the other side to obtain a thickness of 0.2 cm;

- for the formation of the shoulders, in the upper strokes we do 2 cut in the ends;

- on the top of the top bars, we also do a propyl to the navigation;

- the lower and side bars are manufactured in the same way;

- better, if the side bars do immediately with separators, they fix the frame, providing space for the passage of bees;

- drills holes for fixing the wire, one of which will be in the center and two perform on the sides, retreating from the end of 2.5 cm;

- we carry out the assembly either with a pneumatic stapler, or the hammer and nails.

By the way: in addition to such large bitch in the frame design should be avoided, otherwise it will be loosened and under load can break.

Using the methods of beeness in two-circuit hives, you will create bees more opportunities for the accumulation and processing of nectar, and therefore increase your apiary efficiency. On the sequence and subtleties of the manufacture of two-circuits, videos will not only show, but also tells more detail.

Using the methods of beeness in two-circuit hives, you will create bees more opportunities for the accumulation and processing of nectar, and therefore increase your apiary efficiency. On the sequence and subtleties of the manufacture of two-circuits, videos will not only show, but also tells more detail.