During the construction of any building, special attention should be paid to the plaster. Thanks to the application of this layer, the walls receive good protection against moisture. At the same time, the surface of the plaster due to its porosity perfectly passes the air, so that the walls "breathe". This prevents the appearance of fungus and mold on their surface. In addition, the layer of plaster perfectly affects the thermal insulating quality of the wall, due to which the heat loss is noticeably reduced. The wall-processed wall can be coated with any materials: wallpaper, finishing putty "under painting" and others.

Content

Currently, the offer of finished mixtures for plaster surfaces is just huge. The cost of one bag of plaster is now no longer so high as a few years ago. However, given how many bags, not quite a cheaper material can go to one room, the task no longer seems so simple. To reduce the maintenance of repair work, you can cook the plaster yourself. This process is not too complicated, but can significantly save money, due to the low value of the ingredients. How to prepare a solution for plastering walls with your own hands is further in the article.

What makes plaster

In order to welcome the plaster for the walls of the walls, it is necessary to know from what major parts it consists, and which substances are used for this.

The mixture of each mixture for the walls of the walls is two components:

- Binder. This component is responsible for solidification of the solution when it is dried.

- Filler. It not only increases the volume of the mixture, but also prevents it over to heat. Without it, the plaster will be fragile, quickly cracks and collapse.

Properly chosen components of plaster and their proportions, depending on the conditions of its use, will become the key to the success of the entire enterprise.

As a filler for cooking plaster most often use sand. The highest quality for construction work is considered river sand. Career sand quite often has clay impurities, which negatively affects its properties, and in the sea - large salts. When adding sand into the solution, it must be sifted so that the plaster does not contain large pieces. Otherwise, they will reach behind the spatula, leaving the furrow. The size of the mesh cell for sand sifting should be 3-4 mm.

If the filler is increasingly or less clear, then several different components can be used as a binder. Their use depends on what purpose a solution will be used. As binders use:

- Gypsum. This material is usually used as an additive in a lime solution of plaster, which improves its properties. Thanks to the gypsum, the solution begins to capture much faster, and after 30-40 minutes fully solidifies. At the same time, plaster with the addition of gypsum practically does not give shrinkage. Gypsum in some cases is applied in its pure form.

- Cement. This material is the most stronger among binders for plaster. Cement hardness is indicated by numbers. The higher the number on the packaging, the higher the hardness. For the preparation of plaster, the cement 400 grade is mainly used, since there are no hard hardness for this work. Cement, unlike gypsum, freezes somewhat longer. Fully solution based on this material is gaining strength after 28 days.

- Clay. Mostly clay-based plaster is used for internal work. Due to the special qualities of clay, the solutions based on it are excellent thermal insulation. In winter in houses, the walls of which are plastered clay, always warm, and in the summer cool.

- Lime. This is the most commonly used material for the preparation of plaster solutions. For the degree of readiness, lime is divided into:

- harated;

- neighted.

The second for the preparation of plaster, exactly, as for other construction work, does not apply. Before use, the lime must be repayed. Negative lime in the preparation of a solution, which necessarily includes water, enters the latter to the rapid reaction, which can cause the destruction of plaster.

Negarent lime varies in its chemical composition, and, accordingly, have their own veneer velocity:

- Fasting lime has a reaction rate of about 10 minutes. It is falling asleep into the container with water and mix thoroughly. After the appearance of the pair add more water and mix again.

- The secondary lime is quenched by about 25 minutes. It is falling asleep in the amount of about 25% of the capacity, then water is poured to half. As soon as pairs appear, you need to add more water.

- Medle-shaped. Such lime is not filled, but only slightly wetted with water. The quenching rate of such a material exceeds 30 minutes.

Prepare (extinguishing) lime for a lime solution of plaster with their own hands is not too difficult. It is not lime for the preparation of the solution itself, but a lime milk. After the material is flooded with water, his pieces gradually begin to collapse, and the lime temperature begins to grow. Then the crust appears on the surface of the solution. After that, water is added to it and stirred thoroughly. As a result of such actions, solid particles will fall on the bottom, leaving only lime milk on the surface. The latter is filled with a special sieve and merges into a special pit. After 24 hours, a sidewood sand and land is added to the pit. The total thickness of the layer of additives should be 50 cm.

The whole solution is withstanding in a pit of about twenty days, after which it gets from the pit immediately before the preparation of the lime mortar. During this time, lime milk thickens significantly and receives a consistency of thick sour cream. In this case, the lime is quenched finally.

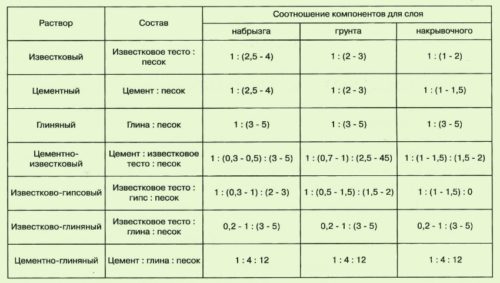

Properties of some solutions for plastering works

To prepare a fitting solution suitable for one or another, you need to know the properties of each of them.

Solutions based on hazed lime:

- A limestrine for plastering walls with their own hands is prepared on the basis of limestone dough and sand. The proportions of the materials in the solution: 1 part of the test of 3 parts of the sand. For better mixing in the container for the preparation of the solution of plaster, water is added. After the end of the mixing is finished, the plaster should have a consistency of a thick test. It is usually used for internal work. Does not have a special strength.

- In order for the lime solution to become stronger, cement is added to it in proportion to 10% of the total volume. This mixture is the name of the cement-lime solution. A distinctive feature of these plasters is a great time of frozen, which allows you to work with them for quite a long time.

- Solution with the addition of gypsum. In the first version of the plaster add gypsum by proportion: 1 part of the gypsum on 5 parts of the lime solution (sand + limestone dough). In contrast to plaster with the addition of cement, the gypsum solution will dry very quickly, which delivers certain inconvenience to novice masters. However, this fact determines its plasticity and durability.

- Clay mix. Such plaster is prepared on the basis of a limestone and clay test in proportion of 1: 1. Differs high strength. Due to the ecology and excellent heat-saving clay properties, the clay is perfect for internal work.

Construction solutions plaster Based on clay. Fully clay plaster is characterized by special cooking technology. Clay is abundantly wetted with water and covered with a dense cloth. After it wakes up, three parts of the filler are added to it. Most often, as the latter uses sawdust or straw. The advantages of such a solution include environmental friendliness, low cost and excellent thermal insulation qualities. However, the strength of such a solution leaves much to be desired.

To increase the strength of clay to the plaster on its basis, cement is added (approximately 10% of the total volume of the solution).

Also, a gypsum-clay solution is also used in the interior decoration. It is prepared in the same way as a lime solution with the addition of gypsum.

Cement solutions:

- Cement-sandy solution for plastering walls with their own hands is prepared in proportion 1: 3 or 1: 4. It is selected depending on the conditions for applying and operating plaster. The more tougher conditions - the more cement.

- The cement-limestone is prepared on the basis of 2 parts of the M-400 or M-500 cement cements with the addition of 1 part of the limestone test and 2 parts of the sifted sand. Cement gives any strength solution and waterproofing qualities. That is why it is often used for outdoor work.

There are two ways to prepare cement-lime mortar. At first sand is mixed with a limestone test, after which cement and water is added to the solution until the desired consistency is achieved. At the second, the cement is mixed with sand, further to the obtained homogeneous mass is added lime milk to the acquisition of the required consistency.

Plastering walls with cement mortar with their own hands - the most common view of the external decoration of buildings.

How to make a solution for plastering walls. Rules for preparing plaster mortar

- When preparing any solution, it is necessary to use materials without impurities in well-specified proportions. The solution itself should be homogeneous, have an average fatness, normally fixed on the surface, and not cracking when drying. Too fat solutions (those whose large content of the binder component) can dry up when dried. When mixing, such a fat solution is too sticking to the mixer blade. In such cases, it is necessary to add a placeholder.

- If the finished solution does not stick at all to the mixer, it is called "skinny". In this case, the supplement of the binder is obligatory.