Chimney is one of the most important parts of the private home heating system. Not only the correct operation of the heating devices, but also the safety of people living in the house depends on its proper design, installation and operation. The poisoning of combustion products is quite frequent incident in areas of individual buildings, and most cases are just associated with incorrect design and errors in the operation of chimneys.

Content

Ceramic chimneys: Benefits and Disadvantages

Why brick chimneys lose popularity

The most common types of chimneys in our country are brick. Simple words, it is a pipe folded from a brick. Then it is just plastered. However, this pipe has a large number of shortcomings. Thus, the structure of brick masonry makes it difficult to the free passage of air flows, which is why the system is lost, which is especially noticeable at the operation of heating devices in windy or cloud weather.

Also, the heterogeneity of such a pipe, and we know that over time, gaps can form between bricks in the masonry, may cause carbon monoxide leakage, which usually leads to tragedy. Another disadvantage of brick chimneys is their weight and complexity of installation.

The brickwork for the chimney should have a massive foundation, as it is quite hard weighs. Installation of such a design is usually carried out only by high-class bricklayers. This type of work occupies a large amount of time. During operation, at the expense of the rough structure of the chimney, soot can accumulate, especially from the burning of coal. Brick chimney must be constantly cleaned from her, because, otherwise, it can cause fire leading to a fire.

Recently, galvanized and ceramic systems come to replace brick chims. It is about the latter we will talk further.

Advantages and disadvantages of ceramic chimneys

Ceramic pipes for the construction of the chimney of the heating device, be it a boiler, a gas column or fireplace, began to be used in European countries for quite some time. In our country, fashion for such systems came relatively recently. Compared to brick chims, such systems have several advantages:

- Absolutely smooth inner surface of ceramic pipes. It is covered by a special fireflower icing, from which it becomes completely smooth, which prevents the occurrence of twists and, as a result, improves craving.

- A long period between service. Such pipes do not need to be cleaned often, as the soot on them is practically not formed. They, in contrast to brick chimneys, should not be deceived by lime.

- High resistance to temperature drops. This property is especially important for solid fuel and combined boilers, in which fuel can be burned with different incoming gases. Also such aggregates can not work constantly, which is the cause of frequent differences in the chimney temperature.

- Ceramic pipes are not afraid of corrosion and other chemical reactions.

- High strength material.

- Easy installation. Chimneys from ceramic pipes are quickly installed. Ceramics easily cuts, slightly polished. Drill a hole in such pipes is not difficult. All these factors significantly reduce the time and cost of installation of such chimney systems.

From the shortcomings, only their cost can be distinguished. However, given those positive points that appear when using such chimneys, this deficiency is leveled. Some of the most popular on the market are Schiedel ceramic chimneys, which are distinguished by strength and high performance characteristics.

Installation of ceramic chimney

Preliminary work

So, how to build chimney from ceramic pipes? Most manufacturers of such systems provide a set of detailed instructions for the installation, in which step-by-step installation, the necessary materials and parameters are described in detail.

Before installing the chimney, you must take into account several factors:

- the power of the heating device and the type of fuel used,

- configuration of roofs and inter-storey floors.

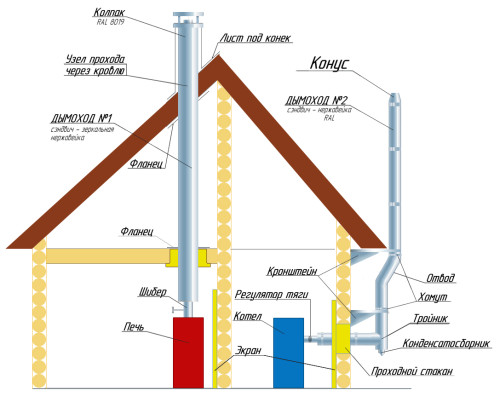

Typically, this chimney consists of the following main elements:

- Foundation. The base under the chimney is flooded separately. Although it should not be so massive, as when mounting a brick design, it is still impossible to do without it. An exception can be a massive solid foundation on which the whole house stands. In this case, the chimney is mounted directly to it.

- Collection of condensate. This is a container in which moisture will be collected, formed from the temperature difference inside and outside the pipe.

- Mine chimney. It is made from special blocks made of light concrete. In some cases, during installation, it is additionally reinforced by reinforcement.

- Pipe section. Ceramic pipe for chimney is for sale. At one end of each section, a coupling is installed, thanks to which the pipes are connected to one system.

Installation of chimney

Procedure for work:

- We start work on the fill of the foundation. At the installation site, the chimneys placing reinforcement from fittings, formwork and pour a basis. To do this, use cement 400 and sand in the ratio of 1: 4.

- After cooling the foundation on it, lay the waterproofing layer. It is better to use a runneroid or a scheduling.

- The first block is set to waterproofing, the condensate collection is mounted inside. From block walls, it is insulated with a layer of mineral wool.

- Next, a protective grille is installed on the block with the condensate collection, and the next block, the first section of the chimney is located inside. Ceramic pipes are mounted on a special sealant, which will have to ensure the tightness of the structure in order to avoid gas leaks.

- Next, we put the next block inwards the tee is installed. The tee is a segment of the pipe, which will be connected to the removal of the heating device.

- Next, we mount the chimney to the roof skate. The main point to pay attention to is the strict vertical of the pipe. Therefore, each block and the installed section of the design check on vertical levels.

- When installing the chimney, the blocks are strengthened by reinforcement. As a rule, they are supplied with holes in the corners in which the armature is inserted and is poured with concrete. Due to this, supports are not shifted from the axis and receive additional strength.

- On the roof in the chimney mine, an audit hole is made through which the necessary work will be carried out. If the chimney from ceramic pipes is installed in the finished mine, it is necessary to do it from top to bottom. To this end, the mounting winch is mounted at the top, thanks to which the master gradually lowers chimney. At each section of the pipe, a special cuff is fixed, the rests of which are installed horizontally, thereby controlling the vertical of the chimney.

- The chimney is going in the same order as in the first example. First, the condensate collection is installed, then the pipe, tee, etc.

- When the condensate collection has already risen in his place, cut off the last pipe so that it performs over the edge of the mines by a little more than 1800 mm. Next, the shaft head and the pipe cone is installed.

Important moment: After connecting each section of the pipe and lowering it into the mine, the chimney is cleaned with a special Schomptol.

As you can see, ceramic chimneys are an excellent solution for the heating devices of private cottages. With their proper installation and operation, the service life of such systems is measured by decades.