At the cottage, a person usually spends significantly less than the time than in his apartment. Most often, the visit is not delayed longer than 2 days at the weekend. Therefore, it makes no sense to conduct expensive heating in the country or in the garage. Nevertheless, it is also wrong to leave these premises without heating. They can be equipped with a large stone stove, but this option is also quite expensive. Today, the industry produces many different types of portable stoves. They are comfortable, safe and easy to install. An example of such heating devices is a furnace for a cottage that uses firewood as fuel. It can warm the room, cook food and heat the water. Almost everyone has firewood at the cottage, so such a stove is easy to operate.

Content

Types of wood stoves

The principle of operation of all wood stoves is the same - during the combustion of firewood, heat is distinguished, which heats the air. Cast iron or durable steel are used as a material for the production of such furnaces. Cast iron is cheaper than steel. Therefore, the ovens are made more often from it. In addition, it is a durable material that reliably keeps heat without losing important characteristics. Often on such a stove there is a flat surface on which you can cook food. Thus, a person who bought a heating wood-burning oven receives not only the heating device, but also the plate on which you can cook.

Hydrolysis oven.

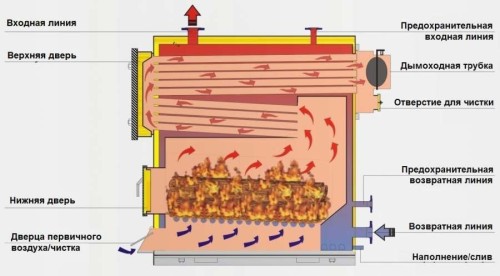

This furnace has two cameras located one above the other. This design allows the use of heat energy obtained both during the combustion of firewood and when burning hydrolysis gas. In the lower compartment there is a damper in which in the closed position from the chamber with the pump, heated air is pumped up. If there is little oxygen, and the temperature is high, then in this case there is a gas formation, with which air is heated. As for the upper chamber, it is equipped with a grid through which hydrolysis gas passes. Such an aggregate can be used, for example, as a wood-burning furnace for a bath.

Single-chamber furnace

Such a furnace gives less heat, but at the cost much lower than the previous one. Material pipes for heat exchangers of this device are metal pipes. In essence, they are one with a combustion chamber. The principle of operation of such an oven is quite simple: the air is falling into the heat exchanger through the lower part of convection pipes. After heating, it goes through the top of the pipe, and cold air comes from its place at the bottom. For this method of heating, there is no additional ventilation and pump.

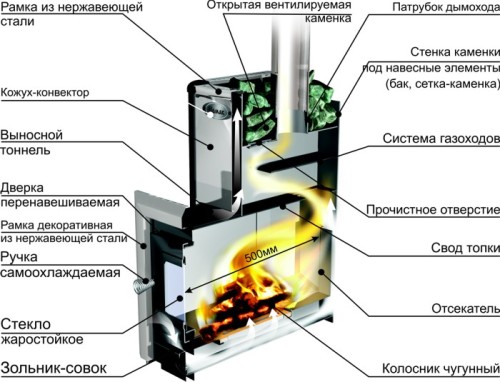

Convection ovens

In the upper and lower part of such a stove there are lattices. The principle of its work is quite simple: the cold air falls into the furnace through the lower grilles, where heats up and climbs up, passing through the double walls. After that, he goes to the room through the top grilles. When the air moves to the furnace, it gradually heats up over the entire surface, which allows you to give maximum heat. While the design is token, the maximum temperature is maintained in it. When the fuel is spent, and the furnace will go out, will already accumulate heat.

Woodwood furnaces

This furnace is functioning at the expense of glowing combustion and works as a heat generator. Such aggregates are heated and reduced the heated air into the room alone without the help of convective pipes. This allows longer to maintain heat in the house. They are also good in that they can work almost on all wood waste. Such an installation due to the presence of a flat surface, it still allows you to easily prepare food. Thus, it can be used as a plate at the cottage.

In addition to the above types of structures, stoves are also produced in the form of heating fireplaces. They will help not only heat the air indoors, but also decorate the interior of the house. In this case, this device is convenient to use. Such a furnace is usually buying in the finished form, since it is very difficult to make it yourself. The most important thing is to choose a suitable place where the design will be located, and the process of mounting the stove is quite simple.

How to choose a place for the stove

Basic recommendations:

- The place where the stove will be located, first of all, should be fireproof. This should take care in the first place. Therefore, it should be excluded the location of easily marked items.

- In addition, the furnace itself must be installed on a refractory stand.

- It should also be provided for a spice for a chimney, which will take the smoke beyond the placement.

If you have little experience, it is advisable to get acquainted with educational materials, for example, you can watch the video to understand how it is done correctly. In addition, it is recommended to hire a specialist who can, at a minimum, provide you with a consultation. When buying a furnace, it is better to be guided not only by its taste. Safety and ease of operation are also important. In any case, you should not leave for a long time without supervision of firewood and coal.

It should be said that today in the manufacture of heating installations try not only as safe as possible, but also of different shapes, sizes. In addition, there is a mass of design solutions, according to which modern furnaces are produced. Products can have a rectangular, square or round shape. They are also angular. Therefore, for each house you can choose a suitable design. To make sure the diversity of similar products on the market is enough to see the photo of the furnaces.

These devices, as already mentioned, serious requirements are imposed. Therefore, it is worth purchasing products only from sellers who are responsible for their sold goods. In particular, the warranty should be provided. Before buying the oven, you should decide what area you need to heat. In addition, it is important to think in advance where you will store firewood. With the right choice, you will get a furnace that will serve you true for many years.

Production of a wood-burning furnace for giving

Masonry woodcover

Furnace wood is a classic heating system for private houses and cottages. Firewood protrude for it as fuel. The masonry of such equipment can be made even with their own hands. Only for this you will need the necessary materials. In particular, the schemes will be required to be focused on the assembly. Before starting the laying, preparatory work should be performed. At the same time, you first need to decide on the installation site, as well as the type of design. There are several varieties of wood stoves. Among them, the most popular are the following:

- Classical Russian with a layman.

- Swedish stove.

- Dutch.

- Sumka.

- Heat and cooking.

In addition, the firewalls mentioned above can be attributed to the wood furnaces. There are other types of heating equipment that are installed in a private house and in the country.

Preparatory work

During preparatory work, you should decide on the type of foundation for the stove. So, if the design has a lot of less than 700 kg, then for her basis, in fact, not required. It is enough to put on the clay solution of the asbestos leaf on the clay solution, after which it is covered with an iron unit. If the oven weighs more than 700 kg, the foundation is necessary.

For masonry, it is advisable to use fine-flow river sand, because It gives less shrinkage. In addition, white or red clay can be used. As for bricks, it is better to take ceramic red full-length.

The width of the foundation must be 120-160 mm more than the dimensions and the length of the oven itself. In general, under the stoves it is best to use monolithic separable bases. However, the use of a column base is allowed.

For masonry furnace you will also need the doors, grate grilles, valves, cooking surfaces and a view. Sometimes to provide hot water supply, it is necessary that the house itself is equipped with hot water. For this purpose, steel water watering boxes or less often brass cabinets are installed.

How to mount oven heating

The masonry of the furnace begins with the preparation of the drawings, on which it is painted, how to place each row of bricks and the necessary metal elements. Such schemes are called "coaches". With their help, collect the furnace is much easier.

When laying, you need to follow several rules:

- First of all, we must not forget that the wood-burning furnace is quite fire-hazardous equipment. So, to provide fire cutting in a horizontal position, the distance from the chimney to beams and the rafters should be at least 160 mm, and even more. This location will save the house from fire.

- If you want to assemble the furnace of a rectangular shape, then angular bricks are installed first when laying. In the future, each row must be checked using a construction level. In addition, it is desirable to measure the corners of the design, which can be done with the help of the square.

- The next step is performed by the perimeter masonry, after which the middle is displayed. For the fuel, it is recommended to use refractory, chamoite or refractory brick, and not a red ceramic full-length. The height of the fuel stove, which uses firewood, is usually made equal to 0.7-1 m.

- A red full-length ceramic brick is preferably in front of a masonry mixed with cold water. If a refractory brick is used for installation, then it is enough to solve from dust.

- The thickness of the seams should not be more than 6 mm. In order for in the future when the furnace is operated, they did not go through them, the solution itself should be laid in a smooth layer. Stacking should be carried out exactly on the relevant drawing. At the same time, one row should strictly follow the following.

- The various chimneys mentioned above, including the frame of the furnace for the furnace, should be fixed with strip galvanized steel. For this purpose, you can also use galvanized or steel wire. It is boated in the seams, after which they are poured with a solution of clay.

- In the last step, the masonry needs to give a wood-burning furnace as you can dry. This must be done before its operation. Test furnace is desirable to spend 2 times a day. Moreover, it needs to be done so that the surface does not warm up. The furnace is carried out until the design is completely dry. For this, it is usually enough one week.

If the described rules and order of work, specified in the drawing order, you will most likely get to collect a furnace that will not smoke and will provide a comfortable temperature in the house. And it does not matter whether it will be cold winter, raw and wet in autumn or cool spring.

Garage furnace with your own hands

In addition to country houses, garages need and in heating, since most such heating premises simply do not. Although many car owners spend a lot of time here. If the heating is available, then most often in the form of a simple electrical heater, which cannot cope with such a large area. Heat they give relatively few. In addition, electricity costs are significantly increased. Therefore, it is still better to use a wood-burning furnace for this purpose, which can be made independently.

The following requirements are presented to the device of such a design for the garage:

- It should be possible to use liquid or hard fuel.

- Small dimensions.

- The furnace must maintain a high temperature for a long time.

- Fast heating.

- The furnace in the garage must be simple in design.

- Convenience in maintenance and operation.

- The oven for the garage and fuel for it should be inexpensive.

Such requirements correspond, for example, reflex furnaces of refractory bricks, wood firing furnaces, various types of so-called bourgeokeces, firing stoves from cast iron, as well as heating installations that use spent materials.

If you want to make a heating device in the garage with your own hands, then not least you need to take care of security. So, the work of the furnace should not strongly reduce the amount of oxygen, which is available in such a small room as a garage. In addition, hazardous substances should not be released when heating the design. It is also necessary that there are no flammable materials around the furnace. For the manufacture of a garage oven, you can use different materials. Consider the most popular and demanded options.

Brick ovens on firewood

In the garage such heating can be found not often. First of all, due to the fact that this option requires a lot of costs as time and money. However, such a furnace usually does not occupy a lot of space in the garage. For masonry in this case, refractory brick is usually taken. In addition, a solution of refractory clay, sand and chamotte powder is prepared. Partially for mounting it is desirable to use chamotte brick. It is especially useful at the level of the heat chamber.

The height of the brick furnace is usually equal to 9 bricks. To take the furnace gases, it is necessary to provide a chimney. Usually it is removed on the roof. It can be posted as the oven itself, from a brick. Inside such a chimney, you need to insert a sleeve made of stainless steel. If you do not have experience in the masonry, then you should consult in advance with an experienced cook so that he explains you all the nuances. Even a small error is fraught with the fact that the stove will have to destroy and collect again.

Homemade Bourgehog

This is perhaps one of the easiest options. This furnace wood-haired can be done quite easily. It is usually welded from sheet metal. As a case, you can still use an unnecessary barrel or metal pipe. From the metal sheet it is easier to make a stove of cubic shape. From the barrel and pipes will be a design in the form of a cylinder. The most important thing is that the wall thickness is no more than 5 mm. Pipe or barrel in diameter should be at least 300 mm.

For this furnace, you must need chimney. It is usually done at the top, but sometimes it is more convenient to make it from the rear wall. If the second option is used, then it is necessary to envisage that the slope of the chimney was at least 30 degrees. In order for the exhaust gases, it is best to use a metal pipe to do this, the diameter of which should be at least 120 mm. Moreover, the thickness of this pipe along the entire length is usually different. So, in the first meters it is about 2-3 millimeters. If the metal material on these sites is thinner, then when heated it will quickly proceed.

In addition, under the furnace it is necessary to provide a place where it will be possible to get a fish out of the furnace. For this purpose, you can use a horizontal metal plate in which the holes are done. It is important to choose their size. So, if you have a small stove that works on small wood and coal, the dimensions of these holes must be about 10-13 mm. If the size of the furnace is large enough, then the slots are already made at least 42 mm.

You still need to install a removable sheet of a sheet of 3 mm thick, in which the ash will periodically accumulate. So that such homemade burzhuyk worked better, the metal plates with a thickness of about 5 mm are delivered to the sides. This will increase the area of \u200b\u200bheat transfer, and, consequently, the garage will warm up faster.

Oil stove

Coal and firewood can not be achieved everywhere. In addition, these are additional costs. Therefore, it is worth considering other options for furnaces. For example, a furnace that can work on spent machine oil. It is usually enough just to find in any garage. That is why such heating has become popular with car enthusiasts.

The design of such an installation is somewhat more complicated than burzhuyki, but it can still be made independently. The furnace that works on the spent oil is, in fact, the H-shaped device consisting of the afterburning chamber, fuel tank, temperature compartment and chimney. When combustion of fuel, pairs are formed, which come to the next chamber, where they are mixed with air. At the same time, additional burning is performed, which provides the device with high efficiency of work.

Sheet metal is used as a material for the body of such a furnace. For the bottom tank, it is allowed to take a ready-made metal box with legs welded to it. It should make a hole with a metal damper. Fuel enters just into the lower tank, and the primary air supply is adjusted using the damper.

As for the upper chamber, it usually has a cylinder form. For its compound with a tank, a metal pipe with a hole with a diameter of 10 mm is used. Through them, a secondary air supply should be carried out into the furnace. Chimney must be installed only at the top of the case.

As a fuel for such a stove, you can use various types of waste oil. Including - transmission, solarium, petroleum and transformer. In addition, this installation can work without any problems on kerosene, fuel oil and diesel fuel. But some flammable substance for such a furnace should not use. This, in particular, refers to acetone, solvent and gasoline.

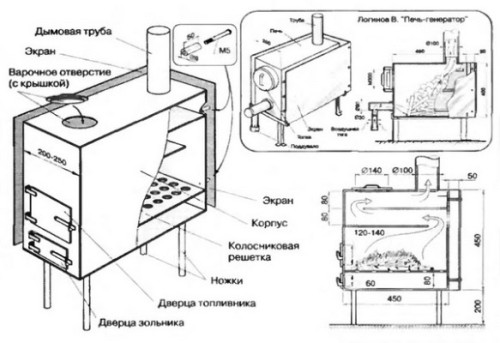

Durable burning furnace

Such a furnace can maintain heat without having to put firewood, more often than once in 10-20 hours. This is achieved through full loading of fuel and the presence in the design of a special damper. The burning in this installation is adjusted by product.

Procedure for work:

- To make such an assembly, it is best to use a specially prepared metal barrel of 200 liters. First, its upper part is cut off, and then it takes a hole under the chimney. In addition, a hole for a pipe with a diameter of 100 mm is cut through, through which air will flow into the furnace.

- To ensure normal thrust, the chimney diameter must be at least 150 mm. After that, you need to make a cargo in the form of a circle carved from sheet metal. Its size should be so that it can freely move inside the case.

- Then the hole is done to which a piece of pipe with a diameter of 100 mm is welded. The load must be inserted into the barrel and cover the cover from above. It remains to make a hatch for feeding firewood and damper to remove ash.

Instead of barrels, it is possible to use a segment of a metal pipe of a large diameter of sufficient length. In order for the design to be more stable, the metal sheet of the square shape can be welded to the edge. Bricks are commonly used as a foundation for such an oven.