If you do not like huge heating bills, I want to live in winter in the winter, and in the summer - in the coolness, it's time to think about insulation events. The optimal option for apartments, cottages, cottages and any other buildings is the thermal insulation of the facade, but in some cases you can work from the inside. If we talk about the materials, it has recently been greatly popular with polystyrene foam for its ease, budget and excellent thermal insulation characteristics. In this article we will describe in detail about the technology of insulation walls by polystyrene foam.

Content

Product specifications

The construction market is replete with all sorts of thermal insulation materials, but the polystyrene foam is rightfully occupied by one of the leading positions. And it is not surprising - it is cheap, durable, keeps warm well, protects against noise and serves a long time. There are polystyrene and its drawbacks, but they do not prevent him from being an excellent insulation.

But before you list all the pros and cons of polystyrene foam, we'll figure it out that it is generally. All its operational characteristics is obliged to special structure. If you look at a piece of material closer, you can see millions of small bubbles filled with air. The finest polystyrene shells constitute only 5-10% of the total volume, the rest is air. Such a solid foam does not miss the cold, quenching sound vibrations and maintains strength for a long time.

If we compare polystyrene foam with another popular insulation - mineral wool, it will be seen that due to the difference in the structure of Minvat, it is not capable of cope with the tasks assigned to it. The thermal conductivity of it is much higher, it is afraid of water (need good vaporizolation), and the shelf life is significantly shorter. With all its hardness and strength, polystyrene foam does not interfere with the inner microcirculation of air.

The video shows how "breathing" polystyrene foam:

The polystyrene foam is resistant to many household chemicals, such as soap or soda. But at the same time, the usual acetone (liquid for removing the nail polish) can fully dissolve it. The same effect will produce aerosol paint, olifa and other aggressive agents containing alcohol. Apply irreparable harm can both the usual sun rays, so after the insulation of the walls of the walls, the polystyrene must immediately close it with plaster.

This is what can do with polystyrene foam. Ordinary acetone:

Types of polystyrene foam

There are two types of polystyrene foam: ordinary (foamed) or PPS and extruded - EPPS. The difference consists in the peculiarities of production technology - extruded polystyrene foam is much more densely conventional. For this reason, there are differences and operational characteristics. The EPPS has high strength at a smaller thickness of the material, that is, when the walls of the walls are inside, it will help to save free space. Heat he also holds better than ordinary polyfoam, and in the summer saves coolness in the room.

It is very convenient that the extruded polystyrene foam is released with a quarter, that is, with special grooves, which, with a dense dock, eliminate the occurrence of cold bridges. Despite the tightness of the fasteners and the lack of seams, the material did not lose the ability to "breathe". True, it is worth such pleasure several times higher than foamed polystyrene foam, but all costs pay off in full with impeccable service.

What to choose to insulate the house? If you are going to work with the facade, it is better to choose a cheap and high-quality foam. Create a closed box from it, it will become a solid and reliable protection for the walls for many years. In addition, this is a good way to quickly and inexpensively align the surface for a beautiful finish finish.

Speaking about work inside the house, it is better to use a thin extruded polystyrene foam, especially if you live in a climatic zone with abundant precipitation and strong wind. Epps water absorption is extremely low, and the sheets are firmly held on the glue.

Facade insulation

Wall insulation is most often conducted outside the house, and the reasons for this are more than enough. First, the inner useful housing area does not suffer. Secondly, insulation is easy to conduct both at the stage of construction of the house and already in the process of its operation. Thirdly, smooth polystyrene plates perfectly smooth the surface and serve as the ideal basis for applying the finishing coating.

The thickness of the sheets of polystyrene foaming for outdoor insulation should be about 10 cm. If you have acquired thinner sheets, they will have to be applied in several layers. Only with a thickness of 9-10 cm can be created reliable protection from cold and wind, as well as reduce heat outflow from the room by 50%.

How is the insulation of walls of polystyrene foam outside:

- First of all, you must prepare the wall - to remove or clean the old coating and align the surface. If plaster is applied on the wall, then it can be left, but if the coating is old, cracked and seeded, it is necessary to get rid of it and sharpen all the holes. Perhaps the only significant disadvantage, more precisely, the complexity of working with expanded polystyrene is that it is necessary to level the walls. Material sheets are firmly glued only on a flat surface.

- When the wall is prepared, you can start gluing polystyrene foam plates. For fixing, special weather-resistant glue and dowels - "mushrooms" are used.

- Before sticking the sheets to the wall, they need to scratch something to make the surface more rough - then the glue will be well held.

- To fix the first lower row of polystyrene plates, it is necessary to attach the base profile, the width of which is equal to or slightly exceeds the thickness of the insulation. The profile installation step is 30 cm. So that it fits tightly to the wall, it is screwed up with special lining washers, and the ends are joined by connecting elements with a gap from 2 mm. At the corners use angular profiles.

- Starting the installation of expanded polystyrene should be bottom-up from the corner. So the sheets will not slide down during the grasp of the adhesive mixture. However, from small movements, not even to occupy professional builders. This case provides for its standards - the maximum allowable shift value of 10 cm.

- Stacking makes online and tight as possible, but at the same time the glue in no case should fall into the place of the joint.

- When the whole wall is placed by polystyrene foam, it should be closed as soon as possible so that the straight sun rays do not harm the material. For this reason, it is not recommended to interrupt work at this stage. On top of the plates are applied to a special adhesive mastic, in which a fine front reinforcing grid is bleated.

Important: When choosing a grid in the store, be sure to check with the seller, whether it is suitable for outdoor work.

The grid is needed to strengthen the surface and increase the rigidity before applying plaster. If you launch the wall right by polystyrene foam (albeit rough), it will not hold on and eventually fall off under your own weight, maybe even with the insulation. - When the mastic gets dry, and the grid will be securely kept inside, the wall covers another layer of mastic to align the surface.

- The printing makeup is applied over the mastic so that the plaster keeps the most firmly as possible.

- Only after this can begin to finish the facade finish - coating with decorative plaster, artificial or flexible stone, siding, etc. We recommend to familiarize yourself with an interesting article on the concomitant topic. Facing facades stone».

The heat insulation of the house outside should be carried out into not too hot, but not rainy weather. Despite the fact that the polystyrene foam is not afraid of water, the remaining materials may be soaked in moisture, and as a result, the quality of work will decrease significantly. The air temperature should be not lower than + 5c. Work is recommended to be carried out promptly, but do not rush and wait for a complete drying of the layers of the material before applying the following.

On the video about the insulation of walls, the polystyrene foam is shown in detail all stages of work:

Insulation from the inside

Immediately it is worth clarifying that if you can warm the house outside - do it. The insulation of the walls from the inside is not too successful idea, especially if we talk about small urban apartments. But if you live in a house that represents architectural value, and change the appearance of his facade is prohibited - nothing can be done - you will have to sacrifice precious quadrature.

The disadvantage of this method also is that located inside the insulation worse protects from the cold and worse delays heat inside. If he is outside, then the frost does not pierces the wall, but remains on the street. Thus, the integrity of the material of the wall is preserved, it is not cooled and does not transmit cold to the room. In the case of internal insulation, everything happens as follows: the wall freezes, the cold faces the insulation, and as a result of the temperature difference, condensate is formed. Slowly, but surely the wall reuses and destroys. To prevent such a bladding perspective helps the organization of ventilation space, but it also "eats" an additional free place.

Unfortunately, this is not all side effects of insulation of walls by polystyrene foam from the inside:

- Insufficient ventilation of the room - if you do not air the rooms or do not put good ventilation, the thermos effect will occur.

- The polystyrene foam is although it does not burn, but when the melting is emitting toxic black smoke, which can harm health up to death.

- To reduce the risk of fire, the polystyrene foam insulation is recommended to close the drywall sheets, and these are some more additional centimeters of thickness.

Nevertheless, there are cases when heating the walls from the inside is the only possible option. The process of mounting the plates itself is slightly different from outdoor and it takes much faster. So, the thickness of the plates is not so large, but only 3-4 cm. That is why the extruded polystyrene foam in this plan wins in the usual one.

How to insulate the walls with expanded polystyrene from the inside:

- The wall surface should be prepared - remove the old coating, if it is a tile, panel or wallpaper (plaster or paint can be left).

- The concrete wall should be processed by primer deep penetration to improve adhesion, and if the wall is made of brick or foam blocks (porous material), you will need to apply 2-3 layers of primer.

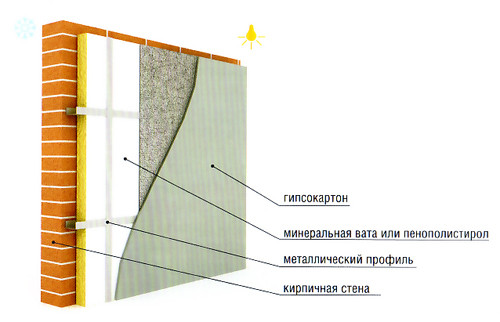

- Do not forget that you must definitely leave the ventilation gap if you do not want to lose the walls in 5-10 years. To do this, install an elementary crate of wooden planks or a metal profile so that 2-3 cm of emptiness remained between the wall and polystyrene foam.

- Put the sheets of polystyrene foam on the crate - the task is not simple, so it can be seen with a thin plywood to create a smooth surface.

- Stick polystyrene plates. In the case of the internal thermal insulation of the dowel, "mushrooms" can not be used, but only to miss the material with mastic.

- When glue grabbing, cutting the walls with plasterboard. It will protect the polystyrene foam from the temperature effects and will create a solid smooth surface.

- It remains to perform the finish finish of the walls, and the work is finished! On plasterboard, you can immediately attach anything - wallpapers, tiles, mosaic, panels, laminate, etc.

Bring out the insulation of walls by polystyrene foam with their own hands immediately after the completion of the heating period (about 3-4 days). Alternatively, you can do this in the fall before turning on the heating, but before the temperature on the street drops below + 18c.

Heat the walls of their own home is easier than simple, it is only necessary to choose the correct materials and clearly follow the instructions. During work at the height, do not forget about the safety technique - in some cases it is wiser to use the services of professional builders.