The stone as a finishing material for the facade is used quite often, the reason for its strength and durability, presentable appearance, the ability to protect the structure from negative external influences. The building lined with masonry looks stylish and expensive, and even those who do not affect natural material, can resort to the help of an artificial stone that will look no worse.

Content

Types of natural stone used in the facades

Natural material has always been highly appreciated in construction for its environmental friendliness and solid appearance. As a rule, in the facade of the facades natural stone uses solid and very robust rocks that are highly resistant to mechanical effects, temperature changes and are able to serve the owners for many decades. Some also believe that natural stone, in contrast to artificial, has a certain energy, which he transmits people. Of course, the price of facing the facade natural stone will be considerable, but those who have the opportunity to not save on quality and beauty, it is better to give preference to the material of natural origin.

In the facing of houses, several popular types of stones are often used. They are distinguished by their appearance, strength characteristics, weighing and other parameters. Consider each of the types of material in more detail:

- Marble - a stone that has the highest decorative qualities among other analogues. In the construction market, it is most often represented in the form of smooth plates with a glossy polished surface, which looks particularly beautiful in bright day lighting. This breed has a lot of varieties that differ in hardness and appearance. The construction sector applies the marble of medium hardness and very high density.

- Granite is another popular, but quite expensive material for finishing facades. The structure lined with granite looks representative, stylish and expensive, emphasizing the status of its owner. This stone is durable and is very durable, it is resistant to temperature differences, strong frost, water and high humidity. Granite is produced in the form of facing plates with a smooth glossy surface, and its color is due to the presence of certain impurities. Depending on the component composition, several varieties of stone distinguish: light gray plaqueing, pink alaskit and porphy-shaped granite, which has a pink shade with gray splashes. It is impossible to go around the fact that the stone necessarily needs to acquire from proven firms that provide all the necessary certificates. Granite bought from dubious implementers may have a high radiation background.

- Limestone, in contrast to granite and marble, produced both in the form of polished stoves and in the form of parts with an arrow surface. For finishing facades, high-quality mountain limestone with a high content of calcite in the composition is used. The color of the stone depends on the impurities that are present in addition to calcite. Often such material is painted in white, yellowish or gray shades. Among the advantages of calcite can be called simplicity of its processing, good decorative qualities, as well as high thermal insulation characteristics that two previous breeds cannot boast. But, unlike marble and granite, the limestone does not have such strength, hardness and density - properties from which the durability of the material directly depends on.

- In facing of facades, sandstone is often used. In appearance, he resembles limestone, but their component compositions and properties are different. Sandstone is available in the form of square, rectangular and polygonal details with a smooth or brushing surface. The stone is not distinguished by glitter and often happens to matte. Among the many sandstone species in the construction sector are popular with several: pizolitic, oolite, lithographic and sandstone-shelter. From the named species for decoration of buildings, oolite and pizolyte sandstones are suitable. Despite the fact that the stone does not differ in high strength, hardness and durability, among the facing materials it takes the first places in popularity, and the secret lies in its democratic value.

- It is widely used in the decoration of the facades and such a stone as a slate. It is polished or unwanted multifaceted or rectangular layers. The surface of the material has a different structure, a variety of protrusions and recesses, besides, a few shades of this stone are available. In the design of houses, 2 types of shale are used: clay and crystalline, the physical properties of which make it possible to apply this material as a facing agent. Slants are characterized by excellent decorative qualities, they can be used as the main finishing material, and you can combine with other finishes. The uneven structure of the stone provides a beautiful game of light and shadow on the finished surface of the house, but at the same time, this material does not have high strength characteristics. The layered structure makes the slate brittle and not durable enough. After the expiration of time, individual parts of such cladding can crumble and crumble.

Types of artificial stone for facing facades

In expensive elite houses, you will not meet finishes from an artificial stone, but for people with an average wealth, such a material will become the best option. Accessive cost, good strength, waterproofability, frost resistance and heat is not a complete list of advantages of such a facing. In addition, modern artificial materials have such an attractive appearance that they are sometimes difficult to distinguish them from natural species. Consider in more detail what kinds of artificial stone are used in the house finish:

- The clinker stone is presented in the construction market in several species that mimic various surfaces, such as brickwork, brick stone, sandstone, etc. Clinker material is made of clay refractory, which is subjected to heat treatment using very high temperatures. As a result of a similar production process, products are obtained with excellent strength characteristics, resistant to temperature changes, as well as long service life. By its reliability and strength, the clinker stone is not inferior to such natural material as facing limestone.

- The cheapest option is the concrete stone, which is quite popular among consumers precisely due to its low cost. The production process of such a material allows you to create elements of various forms and textures by imitating a wide variety of surfaces. However, on the market most often you can find concrete tiles stylized under the crushed stone. The color of such tiles is gray, so after facing the facade, many additionally stain the surface in the desired shade. Concrete tiles The range of material is not limited to, there are other options for concrete stone, imitating, for example, marble and granite. In a similar case, in the production process, raw materials with high strength characteristics are used, as well as special casting forms. Such products are pretty high quality, solid, dense and durable.

- The architectural stone is one of the options described above. It is created from the same high-strength concrete, and its surface is stylized under the sandstone or limestone. To obtain the desired texture allow special injection molds, portland cement, modifiers and a variety of mineral supplements are as raw materials. These fillers improve the operational characteristics of the finishing material, increase its durability, give an aesthetic appearance.

- The polymer sandy stone resembles a brickwork or a brick stone. Most often, this cladding is used in the lower part of the buildings, finishing the ground floor, but also in other parts of the building such a design will look good. As can be understood from the name, polymers and sand are present in the component composition of this material. Polymers are substances resembling plastic and possessing such useful qualities as lightness, hydrophobicity, heat resistance and frost, plasticity. The polymers in the composition of the material are present in the prevailing quantity, the sand is only an additional component. The polymer sandstone cannot be found to particularly durable and solid materials, but it is plastic, due to which it does not crack from temperature differences and mechanical effects. If you compare this type of facing with other artificial stones, then it can be considered the most reliable and hardy.

- A resin-based stone allows you to imitate almost any surfaces of natural material. It is available in the form of rectangular, square or polygonal elements with different texture. The composition of such a stone as a binder is a resin, as well as fillers from natural materials. Often, such fillers are: stone crumb, dust and other waste remaining after processing natural breeds. The final result of production is the material that in appearance is almost no different from the real stone. In the event that ultra-duty resin is used as a binder, such a finish on its decorativeness and reliability is not inferior to natural facing.

- There is also such a type of finishing material as a ceramic stone. It is sold in the form of tiles or bricks with a smooth or slightly embossed surface. Like any ceramics, such a stone waterproof and moves well the effect of humidity and precipitation. But the material is completely unsuitable for temperature drops. From constant expansion and narrowing under the influence of heat and cold, ceramics is covered with small cracks and over time it becomes unusable. The pluses of the material include a good ability to reflect sounds, so that in the houses of the house, lined with ceramic stone, will be quiet and calmly.

Types of facade facade house stone

The style and appearance of the facade in many ways depend on the selected facing material, but the decorative properties of the finishing stone are not all. No less important component when finishing the house is a way of laying a stone on the surface of the wall. The choice of suitable cladding depends on several factors:

- forms of the elements used;

- material textures;

- general architectural style buildings.

Among other things, various processes require different time and physical effort. About the types of facing facade stone We will talk below:

- The design of walls, imitating the masonry from the dice, is most popular because it is considered one of the cheapest options. In addition, such a cladding looks very natural and natural. Stones from a dice have a democratic value due to the fact that in the process of their processing, quite little time and effort is spent. Such stones are not polished, and the ends are often not subjected to finishing, while maintaining uneven edges. For such a masonry, both natural sandstone either slate and artificial materials stylized under the crushed stone are used. The work process can not be called simple and rapid, because for the beautiful wall decoration you need to carefully select the items and shoghes them so that large pass and gaps are formed on the surface. This procedure resembles a layout of a mosaic from different parts and size of details.

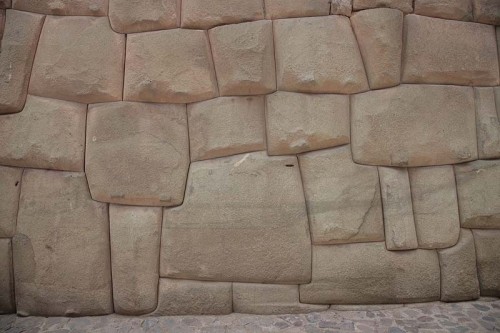

- Building a building with imitation of masonry "Castle" allows you to create a decorative surface, stylized under the walls of vintage locks. In operation, natural materials with an uneven texture are used most often, in shape resembling a tile of various sizes. The shape of the tiles is rectangular, but not perfectly smooth, moreover, individual elements may have differences in size reaching 5-10 cm. Limestone, marble, slate or sandstone are most often used as working material. Since the form at the details are conditionally rectangular, and the edges are smooth, then the stones are joined with each other without noticeable gaps. But during the finish process, you will have to show patience and creative skills, selecting elements of different sizes and harmoniously combining them with each other. It is worth noting that such a work is not for everyone, so those who are not sure in their abilities, it is worth thinking about attracting specially trained masters to the process.

- The wall decoration, stylized under the laying "plateau", is most often used in the design of the basement floors and the corners of the building. Unlike other types of facing, designed to imitate walls laid out of a stone, a decoration in the "Plateau" style performs exclusively decorative functions. It creates from the plates of various sizes, but necessarily a square or rectangular shape. The edges of such plates are smooth, the angles are 90 °, often the ends of the elements have a kaym. The dimensions of individual fragments are different, but a multiple 5, which makes it possible to easily choose the necessary elements and harmoniously docile them with each other. It is possible to simplify this work, in advance of gathering the module from fragments on the horizontal plane, and then moved to the wall of the building. Tiles most often have an uneven texture of the chipped stone, but can be polished to a smooth state. As a material for such a cladding, marble, sandstone, slate, limestone are chosen.

- The design of the walls, imitating the "Shahrior" masonry, is performed from narrow tiles of rectangular shape and the same height. At the same time, the length of the elements may be different. The edges of the fragments are smooth and have a thrill around the perimeter. Facing in the style of "Shahrhar" is relatively simple and quickly, due to the shape of the tiles. In the process of work, there is no need to pick it up for a long time, well-shied with each other. The sale plates with different type of surface are presented: smooth, polished or crushed texture. The latest option is most advantageous, and the first two strongly resemble brickwork. Due to the fact that the work on laying Tiles in the style of Shakhriard does not represent special difficulties, you can cope with such a process yourself, saving to pay by masters.

- The decoration with the styling of masonry "Assol" looks very volume and effectively. The facial side of the masonry is represented by the ends of thin stone dies, as a result of which the surface is very relief and reminds of the type of capital laying. The slate or sandstone is often used as working material. The process of cladding is quite complicated, because all the stones have different thickness and need to choose them in such a way that the difference in the height of the ends as a result created a harmonious and spectacular embossed surface.

- Rondo-style facing is performed from polished rounded stones of different quantities and configurations. Sandstone, slate, quartzite or limestone are used as the main material. The Rondo masonry is well harmonized with a smooth and smooth surface of the walls, so it is often used as framing for windows and doors, for finishing the corners of the house. The process of facing does not represent anything complex. Initially, the largest parts are mounted on the wall, after which the gaps between them are filled with smaller pebbles.

Facing facade stone, photo: