Parquet was always considered a sign of a good taste of homeowners and a symbol of wealth. Such an outdoor coating is characterized by high reliability, aesthetic appearance, environmental friendliness and impeccable wear resistance. The process of its stacking has always been one of the most complex types of work requiring special scrupulsiness and care to details. However, with the appearance of a massive parquet board on the construction market, everything became much easier. Interior design with such material is set even to the novice master, it is worth only to take into account the features of the coverage and some rules for its installation.

Content

Varieties of parquet board

Specialists classify a massive board into two types, which differ depending on the method of production:

- traditional (single-layer board);

- multilayer product.

The classic flooring is made of a solid piece of wood with a comb and a groove on the end side. The result is a massive parquet board from larch, oak or coniferous wood.

The multilayer coating is manufactured by the method of combining various wood breeds, each of which has excellent characteristics. This allows you to achieve the best operational parameters of the parquet. As a rule, the composition of the massive board is this:

- a solid rock wood is used in the first layer, since the strength and appearance of the material depends on this;

- for the second layer, which is perpendicular to the first, use the soft rock wood, because The layer is designed to connect the panel with adjacent lamellas;

- the third layer of the board is made of 4 mm thick plywood.

At the end, the coating is processed by a special composition, which prevents the appearance of fungal lesions and rotting.

Regardless of the type of parquet board, its quality and durability depends largely not only from production technology, but also on storage conditions and installation. Since it is impossible to influence the production process, it is necessary to maximally carefully comply with the rules for laying parquet material.

The massive floorboard is also classified for such types:

- single-band board;

- binary;

- three-band;

- four-band;

- christmas tree;

- network;

- deck board;

- dutch drawing;

These types of massive flooring floors for the floor are the most popular, which is achieved by the impeccable quality of the material, unpretentiousness in caring, ease of laying and reliability.

Advantages of parquet board

Among the advantages of the massive board can be distinguished aspects:

- The coating is pleasant to the touch, completely environmentally friendly and safe for health, which allows it to use it even in children's rooms.

- The massive parquet board of oak, larch, etc. raw materials has a sufficiently high sound absorption coefficient.

- The appearance of the coating is similar to the traditional dialing parquet, but it is much faster and easier to put it.

- Exceptional performance characteristics provide strength, as a result of which the board is not deformed after laying.

- The coating is on sale in the variable color scheme, texture and execution materials, which will make it possible to choose the optimal option under your interior.

Disadvantages of the coating

Despite the list of advantages, parquet board is not devoid of flaws. Among the main of them can be distinguished aspects:

- Flooring susceptible to the effects of external loads, as a result of which scratches, dents, etc. appear in mechanical damage.

- When damaged, the massive board is extremely difficult to restore. Even with a small flaw, as a rule, the entire panel is subject to replacement.

- This coating is also susceptible to water, thermal and chemical processing. For this reason, it is necessary to respect the measures of proper care.

Criteria and subtleties of material selection

In order to choose a high-quality and reliable parquet of a massive board, you need to take into account the number of the following subtleties:

- Humidity of wood raw materials. The optimal indicator for the parquet board is no more than 12%. Otherwise, the coating may be pushing, which leads to the appearance of cracks, chips and slots in the board.

- Technology drying products. If possible, it is advisable to study products of producers and identify which technologies in production one or another brand is adhered to. The most gentle processing of a massive parquet board of laminate - vacuum, in which wood is deprived of excess moisture at a relatively low temperature. As a result of such a drying, the material retains strength, elasticity and proper geometry. As a rule, such products are in the sealed packaging.

- The worstness of the material. The least "capricious" material for the manufacture of a parquet board is oak. When comparing this breed of wood with a more sensitive beech, the deformation period at the slightest change in humidity will be 1.5 months vs. 2 weeks of whimsical beech. The choice of material should be based on the indices of the content of natural oils. These types of wood include ash, irons, tick, merbau and dossia. While the most sensitive rocks are light breeds and fruit trees.

Important! One of the most popular wood breeds - red wood is distinguished by impeccable strength, but there is enough caprica in care. Placing the room with such a parquet, it is necessary to maintain the humidity of 45-50% in the room, as well as protect the coating from the intensive effects of direct sunlight.

- The sensitivity of the material to the light. Outdoor coating during operation can be fused. Faster all their color is losing the breed of mahogany (Paduk, Yatoba, Merbau, Kempas). At a time, as oak, maple, beech, ash practically does not change saturation for long years of use.

Preparatory work before laying

Laying the massive parquet board is made on any base - this can be both concrete and a wooden surface that must be prepared. As a rule, before laying the surface is aligned with the help of a self-leveling mixture. Consider more detailed preparatory work:

- When installing the parquet on the wooden basis, the first thing is necessary to check it on the presence of failures, cracks, squeaks, etc. Defects. If the floor is in good condition, however, small differences and gaps between the floorboards are noticeable, they must be aligned. As a rule, work is to be in cyclishing and spitting surface, after which you can start laying the board.

- If a wooden base has defects in the form of discharged floorings, they must be fixed to lags by means of screws. After that, to produce cyclishing and putty, similar to the previous method.

- In the event that the base of the wood is completely unsuitable for laying the parquet, it is necessary to disassemble it up to the lag, align or replace damaged fragments, and then again collect the entire design.

- Preparation of concrete base is much simpler. To do this, check the work surface for the presence of chips, gaps, cracks and deepends, after which it is to pour the base of the self-leveling screed and wait for the composition to dry. As a rule, it takes 2-4 days.

- If concrete has significant chips, large cracks, depressions, then it is necessary to dismantle the old concrete screed and make a new layer. Only after drying the concrete allowed to stacking the parquet.

Adhesive method of laying an array

The most common option for laying a parquet massif is the installation of plywood base. A concrete floor can act as a rough base of the floor, however, it is mandatory to paro insulating coating. Such a film is stacked by braziness, and its edges must perform on the walls above the level of the plinth.

Mandatory conditions when laying a massive board with adhesive method:

- the humidity indicator of the screed should not exceed 12%;

- in the room, the temperature should be at least 18˚;

- the relative humidity of the air should be from 30% to 60%;

- the height of the flooring and base must comply with the permissible indicators of the norm - 2 mm per 2 m;

- floor base should be purified and fixed;

- an important point is to comply with the instructions for the preparation of glue.

The laying process is made in such a sequence of actions:

- The first thing plywood sheets must be cut into rectangular fragments in size 70x50 cm or squares - 50x50 cm.

- Then the sheets should be put on glue or mastic, firmly attaching dowels. Each fragment is consumed by 6 pcs of dowels.

- After mounting, plywood can be started to lay the parquet array. Two-component glue is used for fastening, but every 30 cm it is necessary to fix the sides with pneumatic studs.

- After drying the surface, the floor covering must be cleaned and polished.

As a disadvantage of this technology, it is possible to allocate that the further use of the parquet after dismantling will be impossible, because The material will be spoiled.

Floating fashion laying

No less popular method, how to lay a massive board is a floating method. It is most appropriate for small-sized premises whose area does not exceed 60 m 2.

The essence is to connect the boards among themselves on the principle of spike-groove. At the same time, the boards are not mounted on the basis. The connection occurs due to the special castle system of the parquet boards. As a result, the connection strength will not weaken during the entire period of operation, regardless of humidity, load and temperature.

It is important to take into account the moment that there are indicators of the maximum width for floating gender. We define the indicators of the castle system of the parquet board:

- 8 m for a massive board, the thickness of which will be 7-10 mm.

- 12 m for products with a thickness of 12-20 mm;

The total sequence of actions looks like this:

- Before laying the board, the surface must be cleaned and seal a special substrate that will serve for waterproofing.

- Then the installation of a parquet array is made. Initially, the first two rows of boards are fixed, which are parallel to the window. To do this, put four chess boards with a gap between the wall and fragments about 10 mm. This distance is necessary to compensate for the place at a temperature expansion.

- In the next, you can go to the second row of boards. They are inserted into the slots in the product of the first row, observing the angle of 20˚. Snap into the grooves.

- After that, put the following flooring and using the timber must be inserted fragments to line up to the stop. Thus there is an array of styling across the area of \u200b\u200bthe room.

- At the end, the last board is mounted - this is the most difficult stage of work. It should be 10 mm shorter than the distance from laid panels and walls.

- It is also necessary to sprinkle the key edge on the groove and fill it with glue. The last parquet board is inserted into this recess.

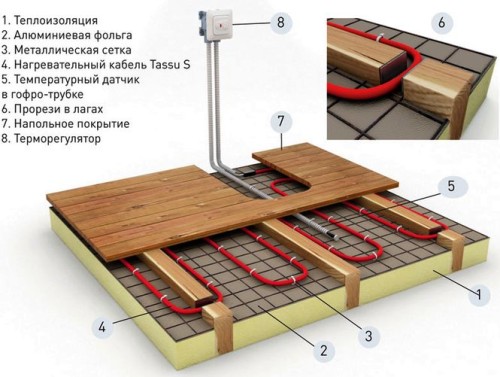

Laying parquet array and warm floor

A parquet massive board itself is a fairly reliable thermal insulation coating, moreover, additional properties provide a substrate. However, if in the room it is necessary to carry out additional heating, the parquet will not be a barrier for holding a "warm floor".

Floor heating technology should be based on water heating, not electric. Otherwise, the risk of fire and the room becomes not safe. In addition, electric heating adaptively affects the castle connecting parquet boards, because The temperature rises and decreases in extremely short time. Due to similar drops, the coating cracks and is subject to replacement.

In addition, before laying, it is necessary to disable the "warm floor" system in advance and give the base to cool to room temperature. As soon as the surface cools can be started to mount the parquet. Upon completion of the work, the "warm floor" can be included no earlier than in 7-8 days, and it is impossible to increase the temperature until the same immediately. It is necessary to sequentially heat the system, increasing the temperature by 2˚ - 3˚ per day.

To all, so that the parquet floor is not deformed, the temperature of the entire coating area should be the same. Therefore, if the heating system is laid in all dwellings, it is necessary to trace the parquet array to end in the doorways.

Caring for a massive board

To increase the service life of the floor covering from the array, some of the maintenance rules should be followed:

- For cleansing it is allowed to use only well pressed rags or dry matter at all. Excessive moisture for such a floor is a negative factor.

- It is also desirable to minimize the amount of detergent.

- A parquet array is susceptible to mechanical exposure, so avoid acute items and heels on it.

- On the legs of the furniture should be put on special rubber or tissue overlays.

- When cleaning, the vacuum cleaner should use only a soft nozzle of the device.

Conclusion

A parquet massive board has become a full-fledged alternative to the classic parquet, expanding the design possibilities when designing rooms. Like any other natural material, such a coating needs to comply with the norms of care and technology of proper laying. Observing some uncomplicated rules, you can extend the life of a reliable and aesthetic gender.

Laying a massive board. Video: