In housing construction, concrete columns are used as the supports of concrete overlaps of the upper tiers. With proper fill, they are able to withstand significant loads for a long time. The fill technology of the column from concrete does not involve the use of complex equipment. It is important to comply with the basic rules for mounting formwork, reinforcement and fill. This will go further.

Content

Types of formwork for concrete columns

Formwork differ in three characteristics:

- according to the design features: there are removable and non-removable, the latter remain part of the column;

- in shape: there may be a square cross section, rectangular, round, oval, multifaceted;

- by manufacturing material.

About the last characteristic should be described in more detail.

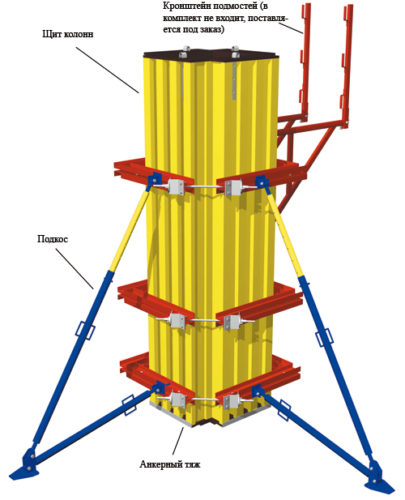

- Metal formwork can be angular, shield and beam-bli. Differs reliability and allows you to increase productivity. The disadvantage is in great weight, in connection with which it will be difficult to pour the columns with their own hands.

- Plastic formwork has little weight, it is easy to clean from concrete. Requires careful circulation (plastic - fragile material).

- Wooden: most convenient for those who cast concrete columns with their own hands. Collected from plywood, OSB plates, boards, bars. It requires tools and devices for working with wood. The technology does not allow casting columns of round and oval shape.

- Cardboard: the cheapest formwork, comparable according to the characteristics with the plastic. Can only be used once.

Important: The manufacture of concrete columns with their own hands using a metal formwork is almost impossible, as it requires the use of lifting equipment.

Calculation of the column fill

To fill the column, it is important to know exactly how much concrete is necessary. The fill must be made in one apparatus, otherwise the structure strength will be reduced. Order of extra concrete - in vain waste of funds. The calculation of the amount of concrete mixture consists of the following steps.

- Calculate the volume of the column (round section) by formula V \u003d πr 2h, where:

- Determine the diameter and height of the column using a roulette.

π \u003d 3.14 (constant), R is the radius of the column, H is the height of the column. To calculate the rectangular and square in the cross section of the column, we use the formula V \u003d ABC, where a is height, B - depth and C - width. In the case of columns, polygonal, oval and other structures of complex shape, the height is multiplied by the cross-sectional area. It is important that all parameters are indicated in single dimension units (in meters).

- We add to the obtained 10%, given the possible losses of the concrete mix at each stage of operation. In the event of the construction of the reinforced concrete column in compensation, the losses are not necessary, due to the small volume of reinforcing elements.

Balaxy Mounting Technology Formwork

The beam-burglary formwork is the perfect form for columns from concrete with your own hands. It provides a high-quality surface and can be used to erect columns with a cross section of any configuration. Installing the formwork is performed in stages.

- It is made of flooring from bars and slab material (plywood or OSB). The flooring is necessary for assembly work.

- Observing the distance corresponding to the specifications on the flooring.

- The beams made from wooden bars are installed across the riglels. The mount is performed by clamps (clamps).

- On top of the beams laid leaf material and fasten it with self-draws.

- The stiffness of the design is provided with the help of bars, which are attached to wooden beams (to the lower ends).

- At the edges of the sheets drill holes for tie screws.

- Shields are connected to each other with twisted screws.

Note: In order to make a formwork for a round column, a special hinge insert is installed between the shields. The formwork for a high height column is collected from the formwork connected by the lining.

How to make a cardboard formwork

The formwork for concrete columns is made of tight cardboard and chains. The amount of mesh (in square meters) is determined by the formula S \u003d 2 πRH. Further actions consist of the following steps.

- Taking into account the size of the column, the framework of the chain grid is collapsed. Cardboard is stacked inside the frame and the contour of the column is formed.

- Studies are installed, fixing the form of the structure.

- Poured a concrete mix.

- Disassemble the chapter after curing concrete (28 days later) and remove the cardboard.

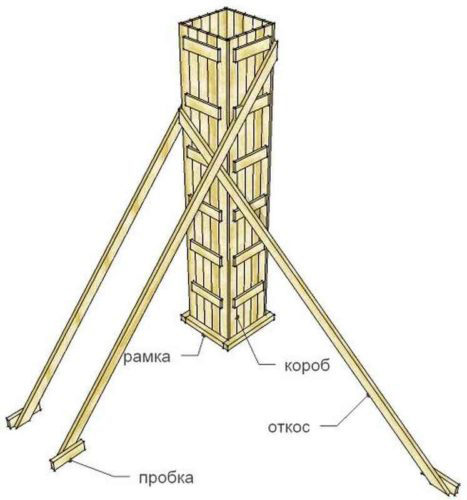

Formwork from boards and bars

The column from concrete with its own hands in the field of cottage construction is most often constructed using formwork from plywood, bars and boards. The peculiarity of the material allows you to create columns of square, rectangular, less often - polygonal sections. The following rules should be followed.

Wooden formwork shields proppate

- The thickness of the boards used should not be less than 20 mm. The minimum thickness of OSB plates and plywood is 16 mm.

- Knowing the sizes of the column, the shields are collected, which are then connected into a single design. Shields are strengthened with diagonal bars.

- Shield connections are performed by self-draws.

- The inner walls of the wooden formwork are covered with waterproofing (rubberoid, polyethylene).

- The formwork is dismantled after complete secretion of concrete.

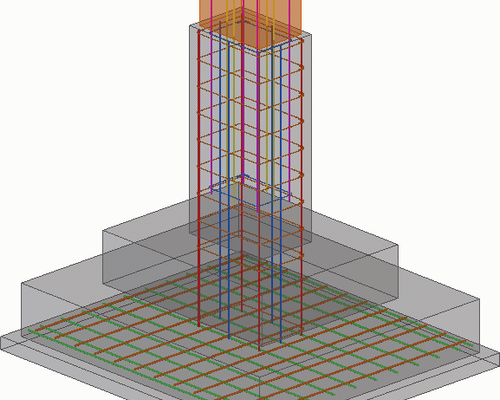

Reinforcement of columns: basic principles

The concrete column can be strong enough under the condition of proper reinforcement. This uses fittings with a diameter of at least 10 mm. The reinforcement pins are installed along the perimeter of the formwork (in the middle of it) at a distance of at least 10 mm from the walls. After 0.5 m, horizontal elements are stacked and attached. The mount is performed using welding and knitting wire.

At the end of the article - the installation of concrete columns with its own hands (video, visually demonstrating the main stages of work).