The facades decoration during construction work requires high quality, attentiveness and diligence. From how correctly the building is completed, not only the external state, but also its operational characteristics depends.

Content

The finishing of the facades is performed using durable materials capable of withstanding climatic effects. Therefore, the facade facade must comply with the requirements and have a number of characteristics. On the territory of our country, seasonal temperature differences can reach about 20 - 30 degrees. A ceramic tile is recognized as the best material for finishing the facade in such climates.

Facade tile and its types

- Typically, the front tiles are made of clinker and porcelain stoneware. Its views are about 10 - 20 species, but the most popular types of facing tiles for the facade are already quite defined.

- In principle, you can finish the walls outside the building with natural stone, more precisely, tiles from this material of natural origin. Just need to be borne in mind that, in other other natural stone, the material in work is very expensive.

- The cost of tiles made of natural stone can be about 2 times more than a similar type of cladding material from porcelain stoneware, which will entail significant costs for the purchase of materials for the exterior wall decoration.

- Artificial analogues are much cheaper, and in this case it does not mean at all that they are the worst quality. Modern technologies allow you to produce practical materials for facing facades, at the same time not inferior in the characteristics of natural stone. This was the reason for their widest distribution in construction practice.

Ceramic granite and its features

- The facade tile of porcelain stoneware refers to widely used types of finishing materials.

- The composition of the porcelain stoneware includes sufficient components for the manufacture of facing materials. It is especially necessary to mark clay, kaolin and mineral supplements.

- Porcelain stoneware has proven itself as high strength material. Its wear-resistant characteristics are far superior to the durability of ordinary ceramic tiles due to special production technology.

- The size of the facade of the facade is essential because the sizes of bars must satisfy strictly specific requirements.

- The process of manufacturing tiles of porcelain tiles passes by pressing a very high pressure. This technology leads to the fact that even the slightest pores on the surface of the finished material are missing. And the subsequent firing at temperatures above 1300 degrees turns the starting material in the monolithic slab, the properties of which in physical characteristics are comparable to the granite of natural origin.

Clinker tiles and its features

- Clinker tiles according to characteristics differs significantly from porcelain stoneware.

- Let's start with the fact that it has a radically different appearance and produce it in a completely different way.

- The form and texture of this material usually mimics the brick. The only difference is that the color of the clinker tiles for the facade finishing can be the most diverse, which allows you to find the facade in the design of the facade, the photo examples of which can be easily found on the pages of construction logs and solutions of modern exterior design.

- In the production of clinker tiles, it is not accepted to stamp products, but, on the contrary, squeeze them from the mass of raw materials. Such a facing tile after drying requires a mandatory firing, which should last about 3 hours. Such material is moderately resistant to reduced temperatures, has a low level of water absorption, as well as known as its high strength. The facade lined with such tiles will not need special care and will not require repair for a long time.

Types of facing facing

The finishing of the facade part of the building with tiles can be performed in two ways of cladding, the technology of which is widespread and is used everywhere. The choice of the preferred method is not determined by eye or complexity, only on the basis of the dimensions of the tile itself and its type. In addition, material is played important role, of which the walls of the building initially are originally made. Their quality determines the need for additional insulation for a comfortable microclimate indoor in winter. Therefore, the facade of the facade of the house tiles is not only necessary, but also an extremely popular type of work in our climatic latitudes.

Facing facade gluing tiles

For facing facade, this method uses a technology that differs little from laying wall or floor tiles indoors. The difference in this regard is only the choice of the type of glue. For the trim, the facade requires a frost-resistant composition of the adhesive substance that will withstand an aggressive environmental impact.

The finishing of the facade by gluing is a very capricious process and requires certain climatic conditions. The air temperature should be from 5 to 25 degrees. Otherwise, the adhesive cement solution may lose its characteristics and laying of tiles on the facade will be performed poorly.

Let us give a brief instruction of the tile sticking technology on the facade. It consists in the next simple sequence of actions:

- To begin with, calculate the surface area of \u200b\u200bthe walls, which we intend to build tiles, excluding the square of windows and doors. After purchasing the desired volume of the cladding material of the selected type, you can proceed to operation. Do not forget to also take into account the surface of all corners in the openings, since the corner elements are necessarily subject to cladding.

- Please note that tile manufacturers indicate the recommended number of bars per unit area, taking into account the thickness of the seam, so the installation on the facade must be carried out at the calculation of this circumstance.

- The surface of the walls before laying the material must be aligned and, if necessary, to be pricked. If the layer of plaster is too thick, a reinforcing grid should be used to align such a wall.

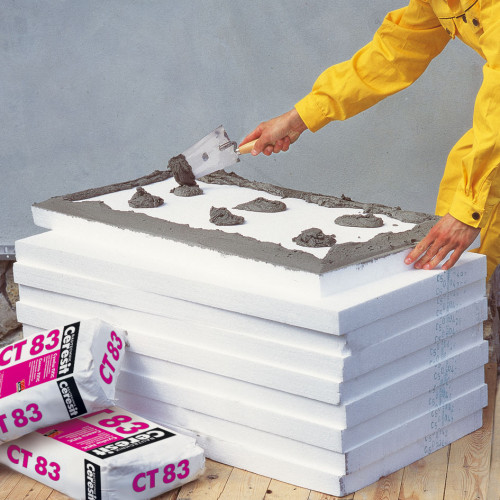

- Further, at the bottom level, it is necessary to beat off the horizontal line and apply the glue composition with a toothed spatula, forming a ribbed profile.

- Tile need to lay starting from the corner. It is necessary to strictly withstand the thickness of the seam with the help of special plastic pegs that need to be purchased.

- An important advice: for better facing the facade glue, it is best to apply not only on the wall, but also for each individual tile, including. The main thing is not to overdo it and control that the adhesive composition does not fall into the seams.

- Often, when laying the tile you have to trim it. This operation is performed by a special disk on stone. On the tile, the line of the cut is noted, and then the adhesive parts are already grinding.

- After a couple of days, the adhesive composition on which the tile was laid will completely dry. Only then can be started to fill the seams between the material with a special mixture using the bunch and the construction pistol.

- Please note that the gluing method for the facade finish should not be used for a large-size porrite tile. If a piece of finishes will accidentally break down and disappear from the wall, it may well be injured by random passers-by.

Facing on the frame: installation features

Many men, and professionals are suppressed, well oriented in the peculiarities of ventilated facades and understand how they are mounted.

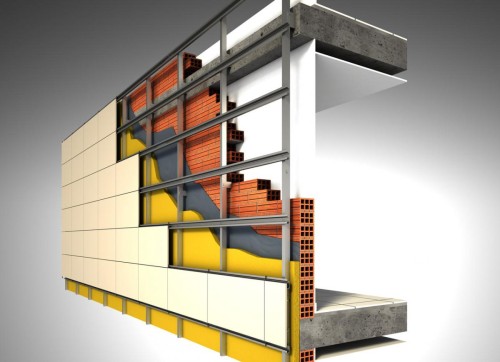

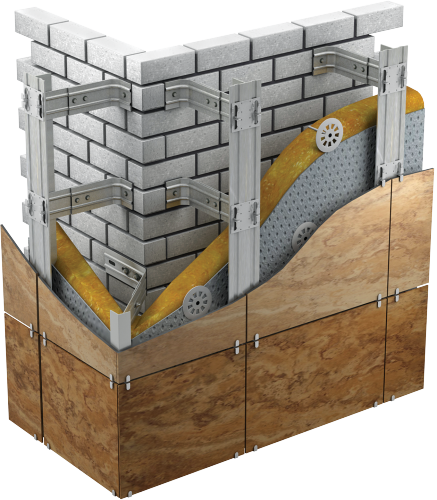

- Hinged ventilated facades can be built using tiles from porcelain stoneware, although it is quite acceptable to use for these purposes and clinker panels. 2. The ventilated facade allows you to additionally insulate the building using hard plates of thermal insulation fixed under the decorative coating of the facade.

- This method is considerably popular because it allows you to warm the construction of the building and create an indoors indoors a more favorable microclimate. This method of finishing is easy to perform with your own hands, which only contributes to its widespread. With due skill, it can be done without attracting professional masters.

Tile on the facade: installation features

- In most cases, the facade cladding tile is represented by products in the form of clinker - material for finishing the facades of increased strength. Such a tile is called clinker. Of course, to mount such a tile of the team of professionals is not so difficult, but is it possible to make a facade with your own hands using a facing tile? Given the volume and difficulty can hardly be.

- There are two ways to external cladding of this type of walls. The tile can be attached to plastered walls or on the ventilated facade system.

- Installation on a plastered wall is a classic look of the external design of the facade. Such a technology is most often applied, therefore, more detailed consideration is worthy, even though the ventilated facades are confidently included in everyday life and construction practice in our country.

Preparation of the Wall

For high-quality installation of the front tile on the plastered surface, so that the facade turns out to be even, the base of the tile laying is perfectly direct. Since we are talking about facing on the plaster, you need to consider ways to align the walls using cement-sand solutions.

- First of all, it is important to remove the old plaster, which is still bad enough. To do this, remove the paint from the facade and remove possible fat stains. The brick wall should be carefully cleaned, for this it is often washed simply from the hose. The brooms will circulate from the walls of dust and cover it with deep penetration, which dries about 4 hours.

- The next step is the markup of the distance of a small length of about 10 cm, and with the installation of vertical beacons. They can be easily glued to the path made with a solution and align in length using a level.

- Since on the same plane it is necessary to place more than two lighthouses, it is important to first set the extreme points, and then move from them deep into. It is easy to do, stretching between the profiles of the Kapron thread, which can be easily located on the outside of lighthouses. Subsequently, the intermediate profiles of lighthouses need to be glued along the cord, and then to produce the final adjustment using a long level.

- Lighthouses must stand at least one day, otherwise they can easily be knocked down with the guide.

- After all that was done, only now you can throw cement mortar on the walls. This operation is conveniently performed by a large craftswoman or bucket. The cement mixture should be prepared in proportion depending on the cement brand, for example, for the 40th in the 1: 4 ratio. Properly diluted solution should reach with zigzag movements.

- Sketching the solution to the area to 2 square meters. m, it is necessary to smear it, evenly tightened from the bottom up. Do not be surprised if corrosion immediately shown on the plaster - this is normal. The main thing is to immediately fill with a solution and stripped with a spatula. Careful alignment will eventually leave only small corrosion. They must be lost the grater in a few hours after tightening the surface.

- If the wall needs a perfectly smooth surface, then the procedure must be repeated after the day with a grater moistened in water. If you are preparing the wall for the installation of facing tiles, careful alignment is not necessary.

- After completing the work on the plaster to the installation of facing tiles, you can begin a day later. Keep the plaster will be simultaneously finished.

- You can use universal frost-resistant and moisture-resistant glue to laying the front tile. The Ceresit CM-11 brand glue is particularly popular in our latitudes, which shows excellent quality fixing and pleasant in operation. Before carrying out this type of work, the wall must be preloaded.

Specificity laying tile

- To lay the tile, you will need a control line for the first row of tiles, and it is better to start with the second. This is due to the fact that the scene is a moisture-resistant coating on the facade of the building, even never happens. There is always a bias left or right. This means that the first row, one way or another, will have to cut a little.

- Glue for work You need to mix the mixer. For these purposes it is better to use a low-sword drill. Type a third bucket of water, and add about 10 kg of glue powder into it, but in any case, according to the instructions. The solution must be insisted for about 5 minutes, after which it is taken again to remove all lumps. The consistency of the solution as a result must be brought to the level of potato mashed potatoes.

- The resulting mixture should be applied to the wall with a spatula, but you can use the little ones. The tile is glued to the surface, but between the strokes, it is necessary to leave a gap of up to 12 mm. To create a gap use special plastic cross-jumpers. The tile must adopt tightly on the wall surface so that the empties are not created for moisture.

- After a few hours, and even days, as time allows, you can start the tile grout. Although, it is possible to start up to the grout, but much more convenient to perform all the work and then focus its efforts on the grout. The grout material should not be too liquid, which it happens in the case of the fulfillment of internal works of a similar type. This is explained by the fact that inside the premises use a glossy tile, which is not difficult to wipe.

- Grouting in the finished form should be similar to the material for a semi-dry tie. It seems dry, but stick off when compressed. Plastering falcon or similar tools you need to dial the mixture and shook using a bunch in the seams between tiles. After half an hour, on the seams, it will be necessary to further go through the extender to make them smooth and eliminate possible defects.

- During the imposition of tiles and when processing the grout, it is extremely important to trace so that no emptiness occurs. Otherwise, water will penetrate them, which at low temperatures will contribute to the plunge of the tile or even a complete splitting of its part.

Tile for facades is the most diverse in size and quality of execution. Porcelain stoneware is also considered clinker tiles, but it is produced in large sizes and is an order of magnitude more expensive. Cerambulants are usually mounted on ventilated facades, from practice - it is not installed on the plaster.