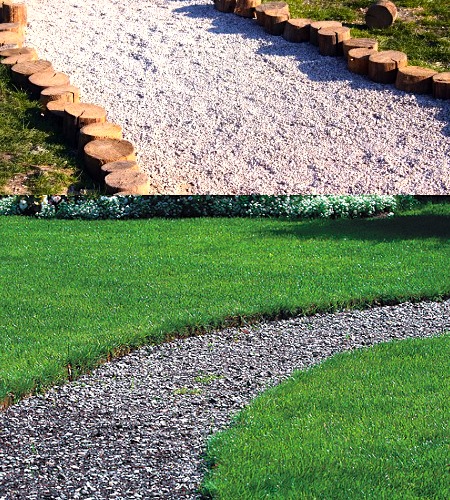

Today, crushed stone is the most popular material for construction, which is used in many of its spheres, ranging from decorative finishes and ending with roads. They are also constantly enjoyed by the employees of the industrial and private sector, equipping gardening and garden sectors.

Content

Crushed stone is obtained thanks to the specialized process of crushing and sorting rocks. That is why it is customary to divide on species depending on what it is made.

Types of rubble

- Lime.

- Slag (created from slags of metallurgical production or by a special method for processing slag melts).

- Quartz.

- granite;

- Secondary (obtained as a result of the processing of construction waste).

- Gravel, etc.

The latter variant is formed as a result of sieving career sand or due to crushing rock. Gravel crushed stone is not durable, so it is often used in the construction of roads and in the production of railway structures.

The limestone type of rubble is not very durable material, but at the same time quite common, due to its frost resistance, waterproof, environmental friendliness and accessibility. It is created by the specialized crushing process of limestone rocks. Such a type of rubble will not be replaced when creating small concrete products, successfully used in the glass industry, as well as when laying road surfaces, which are designed for not a very large load of transport and printing.

Unlike other types of rubble, the limestone type needs special chemical processing.

In this article, we will look at crushed stone, because today it is the most durable and better building materials.

Crushed stone granitis

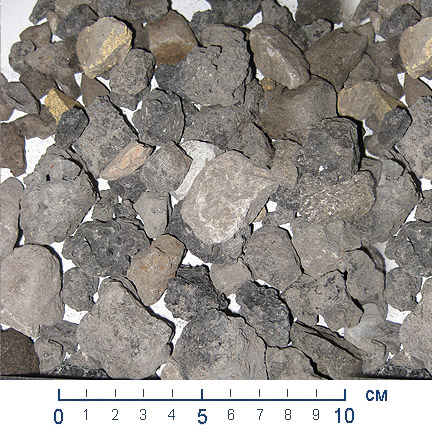

Granite crushed stone is the most durable type of material. It is made of natural granite, which is located in monolithic rocks. At the same time, its education can occur as a result of the natural process of weathering.

Production of granite rubble

The production of granite rubble is carried out with the help of specially intended equipment, which creates a bite of granite rock having a monolithic form.

By virtue of this action there is a large number of blocks, which are then sent to the crushing units. After crushing to the desired fraction occurred, this building material was sieved and divided into several categories.

Crushed stone granite characteristics

- excellent strength;

- increased density;

- high frost resistance;

- hardness;

- the possibility of re-use;

- has excellent water absorption indicators and adhesion;

- environmental friendliness;

- has low brees;

- there are no impurities of chemically harmful and pollutants.

The structure of this building material is the rocks present in the solidified magma - quartz, swarth and mica. And since granite refers to the materials of non-metallic origin, then in such a type of rubble there are no organic impurities. Due to this composition, it is resistant to critical temperature differences and abnormal weather conditions do not affect it.

In addition, the crushed stone granite has various shades (gray, green, pink, red, etc.), which makes it possible to use it in the finishing works.

Fractions rubble granite

- up to 5 mm;

- 5-20 mm;

- 20-40 mm;

- 20-70 mm;

- 40-70 mm;

- 70-120 mm;

- 120-150 mm;

- 150-300 mm.

Crushed stone granite and its use depending on the type of fraction

- The first most small fraction is an explosion of granite. It is used to produce products from concrete, as a decorative building material, as well as to create various types of roads, platforms.

- The second type of fraction can sometimes be used in the form of a mixture of several, for example, 5-10 and 10-20. It is engaged in the production of concrete on granite crushed, structures from it, as well as when the foundation is erected, when pouring road surfaces, bridge and airfield.

- The third type is used to create tram lines, auto and railways, as well as for the production of concrete, railway structures, production facilities and the foundation tab.

- The fourth and fifth type is involved in the creation of concrete and massive structures created from it. Used in the construction of industrial constructions and road construction.

- The last three types (boot) are rarely applied, because they are suitable exclusively for decorative purposes.

The above-mentioned rubble fractions are considered in the options of the most frequent use, however, for each of them there is a huge set of other methods of application. So, for example, it remains indispensable when erecting various hydraulic structures, in the production of concrete nodes, when creating obelisk and colon, etc.

Thus, crushed stone granite, which acts as a natural resource and is amenable to various types of processing, consists of magmatic rocks. At the same time, after the process of crushing and special grinding, it can have a wide variety of shades, based on the amount of impurities included in the minerals. Its use is in direct dependence on the size of its own parts (fractions).