Consideration of the purchase area of \u200b\u200bthe cottage and the cottage today is given quite a lot of attention, because through tracks you can not only get rid of walking on dirt and puddles in rainy weather, but also break down the entire area into a number of functional zones intended for growing fruits, vegetables, februst facilities or devices Recreation areas. The most advanced material for paving the tracks is the paving tile, which possessing high operational and aesthetic indicators, practically disapplied asphalt, concrete and other materials that have been further relatively recently widely popular. In addition, laying of garden tiles does not require special skills and produced very quickly.

Content

What attractive paving slabs attractive?

The popularity of paving slabs is due not only to high-quality characteristics, but also a number of other important features:

- A huge selection of geometric sizes, along with a wide sample spectrum, allows you to create unique ornaments in the process of paving.

- The environmental friendliness of the materials used in the production of tiles prevents the excretion of harmful connections into the atmosphere.

- Easy and cost-effectiveness of installation that does not require the involvement of specialists and special equipment.

- Quickness of all work.

- Replacing damaged elements without the need to disassemble the entire design.

- Durability.

Despite a number of advantages, the cost of certain types of tiles does not have to afford.

Varieties of paving slabs

Currently, the garden tiles are made in various ways from a wide variety of materials, as a result of which the product acquires the geometric shape other than other types, design and qualitative characteristics.

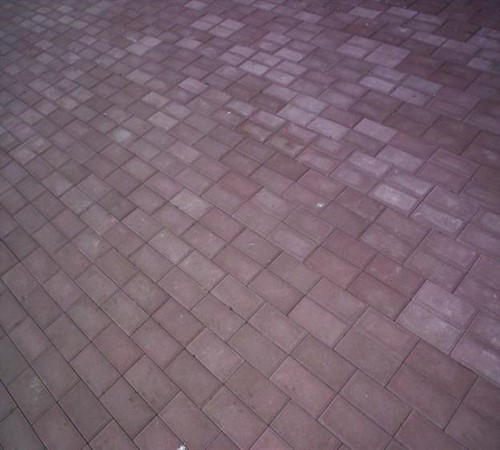

Clinker tile

Finished products are made of certain clay grades by firing at a temperature greater than 1000 ° C, as a result of which the coating acquires a number of preferential features:

- Huge selection of color gamut.

- High rates of frost resistance due to low material porosity.

- Excellent wear resistance, as the color of the tile is homogeneous throughout the structure.

- Good resistance to mechanical damage and influence of chemicals.

- Does not change the original color over a long period of time.

- Durability.

The most significant disadvantages of clinker tiles should be attributed only to the high cost, which is several times the cost of products of the same nature.

The thickness of the clinker tile is 1-2.5 cm, which is enough to arrange the tracks in the garden.

Cement-sand tile

The main components of the tile for garden tracks are cement, sand and various kinds of dyes. After a thorough mixing, the mixture is packaged in the form and is subjected to vibropressing or vibrating.

The advantages of vibropressed tiles include:

- high frost resistance due to low water absorption;

- product sizes are characterized by high accuracy, since production is carried out in an automated mode;

- excellent strength and wear resistance, which causes a long operational period;

- the rough surface contributes to a good shoe hitch with a tile surface, preventing slipping during the formation of the land.

Among the minuses it is worth highlighting:

- the boundedness of the sample spectrum, since the vibropressed tile is released only in red and gray;

- the absence of any ornament;

- high price.

The thickness of the tile obtained by vibropressing is 6 cm or more, therefore, it is ideal for paving tracks that require substantial bearing capacity.

Vibrolite tiles are inherent in the following positive sides:

- huge range of shades;

- the presence of various drawings and ornaments;

- lower cost than in vibropressed products.

Disadvantages of vibrolyta tile relative to vibropressed:

- quite often, a violation of geometric sizes is found, since vibrolite is carried out for the most part manually;

- the smooth surface will not save from slip after rain and in the winter months;

- in conditions of intensive operation, it is possible to quickly abrove the upper layer, as a result of which the aesthetics of the paved path is disturbed.

The thickness of the vibrolite tile varies within 3-6 cm, so suitable for laying tracks with a low bearing capacity.

Rubber tile

The main components in the production of rubber tiles are rubber crumb of various fractions obtained from refining tires, dyes and polymer binders.

Garden rubber tile is made by:

- hot pressing - features clear geometric parameters and medium density of the product at a fairly affordable price. However, over time, the edges of the tile begin to crumble;

- cold pressing is characterized by a higher density and, accordingly, the strength of the product with respect to the tile obtained by hot pressing. In this case, the cost of the coating significantly exceeds the value of the material produced by hot pressing. In addition, in the process of production, the press acts on the surface of the tile unevenly, causeing the inaccuracy of geometric indicators.

Among the huge number of advantages of rubber tiles, produced by both cold and hot pressing, deserve separate attention:

- variety of color solutions and textures;

- excellent depreciation and noise absorbing properties;

- frost resistance;

- the surface roughness prevents sliding in the spring-autumn and winter period;

- high resistance to various types of stretching, chips and other deformations, causing the lack of difficulties in the process of transporting and storing products;

- acceptable cost.

Disadvantages:

- violation of the integrity of the coating in case of accidental impact of acute objects;

- the quickness of the abrasion of the stained layer depends on the intensity of operation.

The thickness of the rubber tile depends on the size of the crumb used for the manufacture of the coating, so the tile is isolated:

- single-layer, reaching 0.6-1 cm thick. For the production of coating, only fine-flowing crumb is used, painted throughout the thickness;

- two-layer, component 1 cm and more. At the same time, the upper layer is made of a painted fraction of a small size, and the lower - from an unpainted fraction of larger size, which are subsequently compressed, forming a coating capable of withstanding sufficiently large loads.

Polymer-sand tile

Polymer-sand products are obtained by melting the mixture at a temperature of 250-300 ° C followed by pressing. Components included in the material, among which sand, polymers and dyes are sintered in a homogeneous mass, which has a homogeneous structure.

Pros:

- high impact resistance, frost resistance;

- excellent wear resistance due to dyeing all the thickness of the product;

- the absence of deformations in negative manifestations of nature;

- division into the necessary fragments is carried out with the help of hacksaw without dust formation;

- when heating does not emit harmful substances;

- prevents the development of mold and fungus;

- preservation of the original color over long life;

- acceptable cost.

However, with strong heating, the garden polymer tile is capable of increased in size, so during the installation process it is necessary to leave small gaps to avoid the slightest coating.

When purchasing products it is worth paying attention to the composition, since the type of polymers used, their share in the total mass of components and other components have a significant impact on a number of operational characteristics of the finished coating.

Plastic tile

Quite often, the tile containing polymers is called plastic, which is not quite true. For the manufacture of plastic tiles, a combination of polymers, various functional additives, as well as dispersed fillers, from the type and quantity of which depend on the properties of the finished product are dependent. A feature that distinguishes a garden plastic tile from polymer coatings is:

- The presence of a locking fastener system by which the assembly of individual elements is being built into the finished track.

- Protruding details that deepen into the ground ensuring the stationarity of modules in a single design.

Positive moments from paving the track plastic tiles:

- huge selection of coverage of various colors, ornaments and textures;

- mobility;

- simplicity and speed assembly;

- beautiful protection against dust and dirt;

- unpretentious care;

- the cheapest coating from the huge variety of paving slabs.

Minuses:

- low strength, wear resistance, as well as impact resistance;

- changing the original color through a short period of operation;

- the need to dismantle the paths for the winter, since the material does not differ in resistance to temperature drops.

Despite the available minuses, Tile Garden Malachite enjoys sufficiently popular among consumers of various financial capabilities.

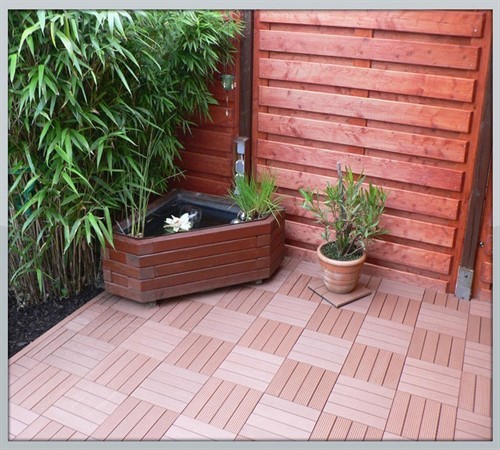

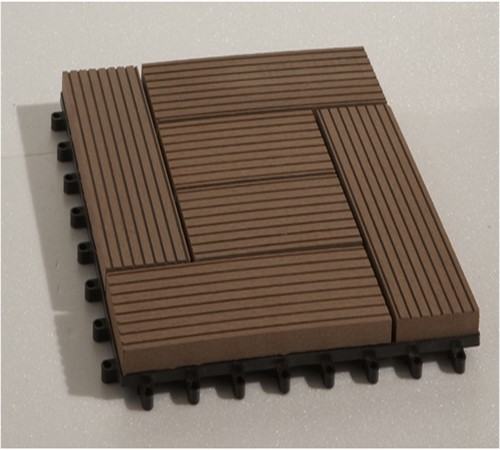

Tile of Polymer Composite (DPK)

A sufficiently new and not well-known wide circle of consumers is a DPK tile consisting of wood sawdust of the shallow fraction and polypropylene.

The explicit advantages of the garden tiles include:

- resistance to the effects of acids;

- resistance to damage;

- lack of warping in temperature drops;

- not exposed to fungus;

- does not fade under sunlight;

- the ribbed surface provides an anti-slip effect in rainy weather and when frosting;

- the presence of a hidden fastener (castle compound) facilitating the installation process.

Unlike plastic, the modular tile is somewhat more expensive, without requiring the dismantling of the design for the winter period.

Gardening modular tile made of DPK is produced by a 4.5 cm thick with a square sizes of 40 × 40 cm, allowing you to lay as a small path between the beds and the central path of any width.

Thus, a large selection of tiles made on the basis of polymers, cement, rubber and other materials, allows us to construct paths for various purposes.

Shot tile laying technology

Before laying a garden tile, it is necessary to hold a number of preparatory activities.

Planning

The correctness and care of the preliminary work affects the duration of the operational period of the future coverage, so the fulfillment of all items should be as responsible.

Prerequisites contain the following steps:

- determination of the size of the track. The length of the track depends on the characteristics of the site and personal preferences of the owners. At the same time, the width is determined at the rate of the number of people who constantly or periodically use the future track, as well as the destination and location of the track (for the central path, which will be able to move nearby near 2 people, is 50-120 cm, and for adjacent paths intended for adjacent paths For a shipping trolley, a width of 70 cm is suitable);

- drawing. Measured measurements are applied to the drawing with an indication of an inclination angle (0.5-2%), which is necessary for flowing water from the surface of the track. If the track is planned to be laid next to the house, the bias are made in the opposite direction from the structure, and if at some distance from buildings, the slope is made from the center of the trail to the edges. In addition, when placing a track, close to the house it is necessary that the coating is 10-15 cm below the top edge of the waterproofing layer of the foundation. Otherwise, the floors of the first, as well as the basement will be mounted in rainy weather;

- selection of laying scheme. Numerous types of tiles are produced not only square shape, but also in the form of a rectangle, waves and other figures, therefore there are many options for laying a garden tile, which look below;

- calculation of basic materials. The number of edges required \u003d path length * 2 / Method of one border. Power area \u003d length * width of paths. The number of required tiles depends on the size of the elements \u003d Power area * The number of tiles in 1 m². At the same time, it is necessary to purchase a garden pavement tile with a reserve of 10-15% with a simple laying scheme and 20-30% when creating a pattern, diagonal masonry or the use of intricate pavement elements.

Marking site

Reproduce the drawing on the land plot using the cord, roulette and pegs.

If the slope is made from the center to the edges of the path, then:

- On both sides of the track, pegs are installed at the same level relative to each other, between which the fishing line is stretched.

- In the center of the path, every 3 m, extra pegs are placed, between which the fishing line is stretched so that it rises above the extreme fishing racks by the size of the desired slope.

If the slope is planned to be done in one direction, then:

- Install the pegs of the zero level.

- The cord is stretched.

- The initial peg of the opposite side of the path is installed perpendicular to the first peg of the zero level, taking into account the magnitude of the inclination, i.e. The line of the second row of pegs will be located above the zero level line.

In the process of the arrangement of the pegs, it is necessary to check the smooth track of the width with the help of the rule. If the track is somewhat wider than the rules, it must be divided into additional strips. The degree of inclination is controlled by the construction level.

In places where the fishing line is close to the soil, it is necessary to relieve elevations, and in the presence of deepening - to plug the soil and the ramp, seeking the distance between the fishing line and the soil it is equally around the perimeter of the set pegs.

Thus, the stretched fishing line indicates the level of the upper edge of the path.

Preparation of the foundation

The laying of the tiles directly to the soil threatens the coating displacement through a fairly short life, as well as the appearance of cracks and other deformations due to drops and recesses available in an unprepared base, so the following order works before laying:

- The top layer of the soil is removed to the depth of 10-15 cm. At the same time, encountered roots, plant seeds are removed.

- The bottom of the dug in the trench is rambling.

- On both sides of the trench, there are separate grooves on the width of the curb, thoroughly tamper, after which the sand layer is poured about 5 cm, which after moisturizing it is still tamping.

- On 3/4 grooves, the diluted cement mortar is poured, in which the curb is installed around the perimeter of the entire track.

- The bottom of the main trench is falling asleep by 10 cm rubble, it is rambling.

- A geotextile spread over the rubble to avoid the subsequent wake of the sand.

- 5 cm of sand is poured, wetting carefully and tamper.

If the car is planned to pass the car, then an additional layer is created over the sand, consisting of a cement screed with a layer of 3-5 cm.

Process laying

Installation of tiles is taken upwards, if the track is located on the slope, and on itself, if horizontally, as follows:

- To put the first tile, even on the lines of markup and horizontal.

- Drink tiles to the required level by means of a rubber hammer.

- Similarly, laying the remaining tiles, leaving the gaps between the individual elements in 2-4 mm.

Every 3-4 series should be checked properly routed via level and immediately carry out an adjustment of misfolded elements.

If in the process of paving meet protruding from the ground elements (column, gas pipes and other obstacles), then, without breaking the pattern, laid out the whole tile, and made installation of fragments that need to be cut at the end of the installation.

Finishing work

At the end of the garden paths paving tiles to fill in the seams dry clean sand:

- Sprinkle sand on the coating surface and using a broom located in the gaps between the coating.

- Thoroughly moisten from a watering can or hose.

If necessary, repeat the procedure until moistened sand will not be on the same level with the upper edge of the cover, and in 1-2 days you can safely use a brand new track.

Thus, the ease of placement of any type of paving slab contributes to the vast possibilities of creating a unique masterpiece in the form of tracks, which will not only be the main decoration of landscape design, but also will create excellent conditions for the movement on the site in rainy or snowy weather.

Finally, look at the garden tile laying video, which clearly shows the entire process: