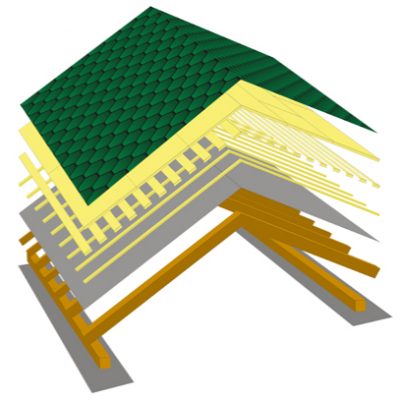

The construction of the rafter roof is practically independent of which materials for this will be used. There are long-established roof structures. The skates most often form an equifiable triangle: such a form is the most optimal from the point of view of aesthetics and the rational spending of building materials.

Content

How to create a soft roof

The algorithm of the action of roofers in the device of the roof of this type is next.

- Setting rafters.

- Installation of a solid crate.

- Sheathing with galvanized sheet material from steel of hearing windows, rashobodkov, endands and places of penetration of pipes.

- Laying with a soft roof (starts from below and continues up).

- In the underfloor space (if the roof is attic) laid waterproofing material - rubberoid, polyethylene film, hydrobarrier or only. Between the insulation and the crate must be a ventilation gap in the range of 20-50 mm.

To understand everything, you need to consider in detail every step of work.

Device of the rafting system of the roof: technology of work

The roof can be constructed with a hanging or a sling lines. The process can be divided into several stages.

- Preparatory work. It is necessary to measure the height of all walls and eliminate the discrepancies that appear during the masonry process. With the help of a level and plumb, you can make sure that such discrepancies can be within 1-2 cm. In addition, the corners of the house may deviate from 90 ° and, if possible, should also be corrected. For houses made of brick and concrete blocks, a cement-sand leveling screed is used for wooden - lining bars and rails. This is necessary because the calculation of the rafter roof is performed for perfectly smooth surfaces.

- Laying Maurolat. Initially, the waterproofing material is placed on top of the attic overlap (usually - ruberoid). Maurylalat will lie on it and (if it is provided for by the design) Liezhalan. You should know that Mauerlat can compensate for the deviation of the angles from rectangles.

- Under the layer it is necessary to lay two layers of rubberoid. Fasten it with a bracket to the inner walls of the house. You can use anchor bolts. It is necessary to check the horizontal position of this part of the roof.

- Installation of racks and runs. If the roof is going without a bit, the rack is necessary. Their location is calculated in advance. Fasten them at the bottom of the fights to each other near each rafter foot (to support the latter) in a vertical position. After aligning the horizontal surfaces of the walls, the racks are made of the same length. The run may be one (skne), but often install additional - on the sides.

- Mounted a slingful system for a soft roof. For the convenience of work, the forests should be built. Marking of the rafter feet can be made according to the template if all of the above conditions are made. In the event that deviations in the height and corners of the walls are too large, it is necessary to mark the markup for each rafter foot. Initially, the extreme legs are attached, stretch between them the cord, which is focused, measuring the remaining rafyroids. The distance between them is measured by measuring regions. The assemblies of the rafter roof are connected by the "wrinkle" with the help of brackets, nails and self-tapping screws. After that, the "Filkings" is fixed: they will support the eaves. The length of such a sink should not exceed 0.6 m. It is sewn with a handy material.

- Rafter roof trusses of this type involves setting increments in the range of 0.6 -. 2.0 m distance is selected depending on the kind of wood and the design load. After installing the rack is attached to the walls of the house with the help of wires and anchor bolts: it is necessary to prevent structural failure of the wind.

Your attention videos showing truss installation

Lathing for soft roof

After be erected roof truss system, proceed to lathing apparatus. For the soft roof used solid single- or double-layer. To do this, use these materials:

- OSB - oriented strand board;

- eaves and decking;

- FSF - water-resistant plywood.

The main goal - to create a flat surface slope. Each of these materials has certain advantages and disadvantages. The following rules must be observed during installation.

- Lumber - the cheapest material. Better use softwood planks width of 150 mm and a humidity of 20%. It is necessary to select the same thickness in order to reduce fluctuations in the level. The length will depend on the distances between the rafter. Boards are placed in compliance with the clearance of 3-5 mm it is necessary to compensate for thermal expansion.

- WBP plywood and OSB panels are laid parallel to the long side of the ridge. The joints of adjacent panels in parallel rows do not overlap, which plates are displaced horizontally. If the device of the roof truss and installation of lathing is done in the winter - a gap of 3-4 mm is required to compensate for the expansion of the material with the onset of summer.

The device is a continuous two-layer crates

This crate is combined differs cheapness, and at the same time reliability. In its construction used OSB plates and PSF lesser thickness. Sequence of operations during installation.

- Set rafters.

- At a distance equal to the size of PSF or OSB sheathing stuffed, which is used for lumber, edging or edged boards.

- Above the batten is fastened PSF plywood or OSB (using screws and galvanized nails). Observed pitch between sheets of sheathing of 300 mm at the juncture of the sheets - 150 mm. Stacking is carried out in a checkerboard pattern.

Laying soft roof

At this stage, observe the following rules.

- Rolls of roofing felt on the slopes with a slope angle of less than 15% is rolled downwards: it will be provided a better water drainage.

- The number of layers of roll coating depends on the angle of the slope slope: if it is less than 10% - the three layers of the tag substrate and two - reinforcing are mounted. If a bias within 15-25% - add the top layer of paint.

- For outer waterproofing, materials are used with a sprinkling of large abrasive grains, for the inner - rubberoid, only pergamine.

- In the event that the bias of the roof does not exceed 5%, the elements of the soft roof (bituminous tile, rubberoid, etc.) are stacked with a punch of about 100 mm.

- In the event that a small diameter ventilation pipes pass through the roof - rubber seals are used for sealing.

- In the places of the roof adjoining to the vertical surface, it is necessary to lay a roofing material with puff and protect it with a metal apron.

Correctly mounted rafting system and soft roofing material serve at least 50 years, reliably protecting against atmospheric precipitation.