Despite the fact that with the help of modern technologies, many new outdoor materials have been created, a popular massive board for the floor remains. Laying it is available on its own, everyone who knows how to handle a hand tool. Before proceeding with the work, you should find out how professional laying of a massive board is performed. This will help choose the optimal method of installation depending on the humidity and air temperature in the room.

Content

Properties of material

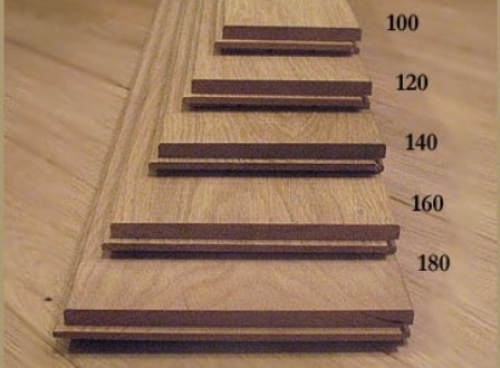

The massive board is characterized by high strength and durability. It is able to withstand reusable grinding, due to the fact that it consists entirely of wood. Boards can be from 100 to 180 mm width and from 500 to 3000 mm long.

For the convenience of docking on the end sides of the boards there are ridges and grooves: with their help, the floorboard is tightly connected. The chamfer is removed from the outside, thanks to which there is always a gap between adjacent boards. A small deformation does not lead to the curvature of the flooring: the clearance is filling, which compensates for the material voltage. To prevent deformation on the bottoms, longitudinal feeders and notches located perpendicular to propuls are performed. It also removes the voltage of the fibers.

The material does not change its properties if the moisture of the screed does not exceed 6%, for overlaps from concrete - no more than 4%.

Choosing a massive board

The array boards are made from ordinary trees and exotic breeds. They differ in color, surface texture and moisture requirements. Lightly wood wood is ash, alder, larch, beech, hornbeam, Sukupir, Meranti, Karagach, Mersava, Siam. Pink shade in cherry, cherries, sury and pears. These breeds can be operated only in normal humidity. It is impossible to use electrical heaters in a room with such an outdoor coating.

In rooms with non-permanent humidity and temperature drops, laying of a massive parquet board containing oils in large quantities is recommended. This includes Merbau, Oak, Lapacho, Kumaru. Breed of red-brown shades: Kearsja, Belian, Yarra, Belian, Merbau, Iroquo and others. Dark rocks include: Berny oak, rosewood and Venta.

It is important to take into account the type of room. Where the load on the floorboards (in the halls, hallways), it is planned to lay a massive solid boards - ash, teak, oak. Such wood is more resistant to abrasion and deformation. In the bedrooms and living rooms you can lay out the floor covering any breeds.

Preparatory work

The massive board in front of the flooring must be unpaved and withstand at least five days indoors. The material is placed by stacks on lining with airbags between them to ensure air circulation. This is required so that the board takes the final form and is not deformed after laying.

The base should be aligned in advance, it should be dry. Garbage and dust must be removed. There should be no sticking nails.

Massive Board Stacking Technology

Before entering the installation of the floor material, it is necessary to finish with other finishing works. Ventilation and heating systems, window blocks and doors must be installed, the walls are lined.

The floorboards are stacked by the same principle as laminate, but fasten additionally to the base with self-draws, which are screwed from the spike. The boards are snugged with each other with the help of wedges. It is impossible to stream close to the wall: zador from 5 to 10 mm is necessary to compensate for thermal expansion.

The first row orient the groove towards the wall. Self-tapping screws around the edge in such a way that they can be covered with a plinth. The place where the hat is impossible to close the screw, close the wood with a putty on the tree. Halfing along the direction of propagation of natural light: it makes the grooves between them less noticeable.

Massive Board Methods

The massive board is laid on various bases: on overlappings from reinforced concrete, on the cement-sand tie, on the paneur, on the lags, on top of the tree. The floating method of installation is used (the mount is carried out by brackets or screws) or adhesive - to the substrate. For each of these methods, there are features.

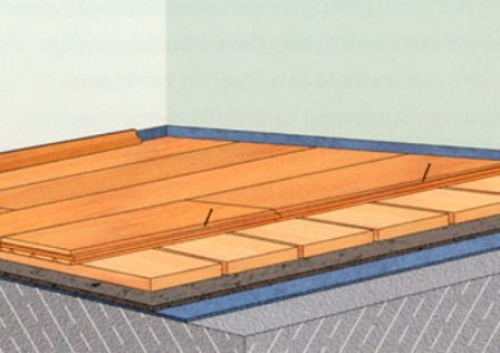

Styling on the cement-sand tie or concrete

Wherein:

- Special glue, withstanding temperature differences (thanks to this, the boards can be fixed on the heated base);

- Before mounting, the flooring is convinced of the strength of the screed and in the fact that its humidity does not exceed 6%;

- To check the humidity at different depths of the screed, drill several non-through holes;

- When the level of moisture is exceeded, the polyethylene film is placed.

Laying a massive board on Faneru

The following works are performed:

- Phaneur is cut into squares 500 × 500 mm or 500 × 700 mm rectangles;

- The resulting squares are fixed over the base with glue, after which the dowels are used (5-6 per sheet);

- Check the humidity of plywood: it should not be greater than 10%;

- The board array is laid on the Faneru using two-component glue;

- Each floor is fixed on the side of pneumoshpilts;

- Outdoor coating is subjected to light grinding.

Sophisticated areas are first laid out without glue. It is necessary for proper fitting boards. The room should be closed: drafts when installing boards and drying glue are not allowed.

Technology Compliance laying solid wood affects the duration of the service life of the material. Excessive moisture, dirt, offset veneers lead to its warpage.

Installation for coating wood

Work is carried out in the following sequence:

- checked the old base for strength;

- surface treatment is performed using a grinder with the grinding belt (it is necessary to align the base and removing old paint layer);

- the base is cleaned of debris and dust;

- stacked sheets of waterproof plywood of 18 mm thickness;

- sanded plywood blister layer;

- laying floorboards new coating is performed with the same orientation as that of the old base boards.

For fastening with screws boards used anticorrosive layer.

Laying solid wood floating way

In this case, the new coating is not connected to the base: the boards are held together only dies. This method allows the coating to easily adapt to changes in humidity and temperature, as well as to withstand significant mechanical loads. The floating method is most suitable for floor heating. Other advantages of this mounting method:

- laying a cheaper solid wood: stacking price 1m² twice lower than when using another method;

- simplicity and speed of installation;

- efficiency and environmental friendliness: adhesives and primers are used during installation;

- repair and replacement of the unit cell to perform easier;

- less likelihood of deformation due to the lack of attachment to the base.

Fastening aluminum brackets with silicone compensators gives reliable connection plates.

Stacking the boards on the joists

This method is used if necessary to quickly build floor coating without the use of "wet" techniques. Before decking planks stacked array of waterproofing material - polyethylene film having a thickness of at least 0.5 microns or penofol used. Between joists are placed mineral wool insulation. Under the boards to be assembled from sheets of chipboard base.

Sami lags must be equal, lie at the same level and the distance between them should not exceed 1.5 m.

Installation with adhesive substrate

The process consists in stacking the substrate with the adhesive side toward the bowls. substrate mounted on top of a floor covering made of solid wood. This method has several advantages over the other:

- elastinola substrate has acoustic and thermal insulation properties;

- Not noticeable place of docking of the flooring;

- The swelling of the material is practically excluded;

- A reliable clutch of boards is ensured with a base due to the adhesive layer;

- No need to mount an additional basis.

After the boards are laid and ground, the floor surface is covered with moisture protection and damage. For this, various varnishes, wax and special oils are used.