Slopes from plaster remain in demand and relevant type of finishing works for many years. And if at first glance it seems that the manufacture of slopes of doors and windows in this way is a challenging task, then reading this article, you will understand that this work is working for everyone. So, consider in more detail how to make slopes with plaster.

Content

Advantages and disadvantages of slopes from plaster

- Slopes from plaster have a number of advantages.

- The frame becomes more stable.

- Installing such slopes increases noise insulation.

- The existing small cracks in the seam between the wall and the window frame are closed, due to which dust does not penetrate them.

- There are no cavities for the accumulation of moisture, thereby not creating conditions in which mold and fungi could develop.

- Such slopes have resistant to temperature drops.

- From visual advantages, it is worth noting that it is possible to make a window outline differently, for example, to paint the layer of plaster in the same color that has a frame.

Silence from plaster also has its drawbacks. Here, first of all, you need to note the unwillingness to deal with mud, namely with cement-sandy solution. In this case, the process of performing work is quite long. After all, the slope consists of several layers, each of which must be dried, and only after that you can apply the following layer.

Instruments

If there are advantages for you to be advantageous, and you decided to make a plaster slope, then you need several tools.

- You will need a rule with a limiter - it can be a small or special corner. Malka is a simple wooden bar, whose end is a nail. It can be made of plywood strips from the ends carved in the form of the oxo of the window frame.

- It will take a high Rule Lighthouse, which should be a little longer than the height of the window.

- From the tools you will also need trowel, grater and half-sash, a round max brush or a pulverizer, and a container for a solution and water.

For plaster works, the following materials will be needed:

- Cement-sandy solution with lime. Any suitable.

- Gypsum.

- Mounting foam or construction wool as insulation.

- If the frame is plastic, then the silicone sealant is necessary.

Preparatory work

Before the plaster of slopes, the window requires some preparation on which it depends on how convenient will be further work. In particular, it is recommended to install window sills in advance. Otherwise, in the plaster of the slopes, you will need to close the slots between the side slopes. In addition, the installation of the window sill will make the installation stronger. But it should be noted that during the works, the windowsill may be damaged or a solution can fall on it. Therefore, it should be protected using a layer of paper or pieces of drywall.

- The plaster should be applied only on a clean surface. Therefore, you need to remove various pollution from the window opening. This may be, for example, the remains of old paint or plaster.

- In order to increase the decay of the solution with the base, the surface should be projected. You should choose a primer, depending on the building material, from which the window opening will be erected.

- Before putty, it is also necessary to clean the handle and radiators of heating. The window unit itself should be closed with a film by gluing it to the window with slices of painting scotch.

- In addition, steamed vapor barrier. You can use a special vapor barrier film. Instead, it is possible to use silicone sealant, which has resistance to low temperatures.

Plaster slopes windows

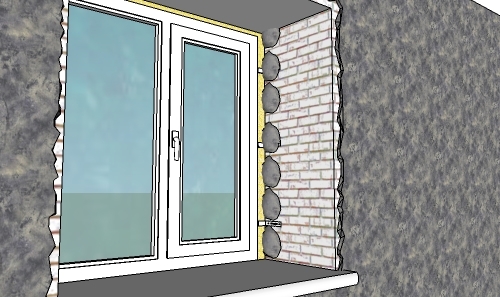

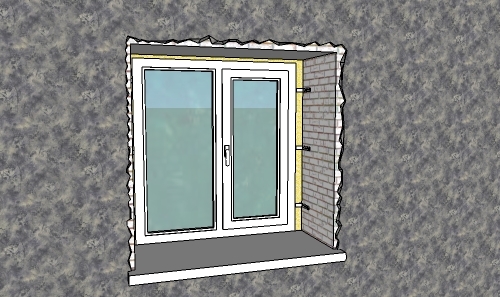

- In the plaster of slopes of windows, the template will have two supports - this is a window frame and a rule that must be pre-exhibited by one level with a frame. At the same time, the rule performs two main functions - this is the role of the lighthouse and the role of the pointer, where the end of the plane of the window slope is. Thus, we can get a smooth outer angle.

- Suppose that the walls in the room are already plastered. Then before proceeding with the plaster of the slopes of windows with their own hands, you must first set the angle of the solution. To this end, you need to attach a square in a place closest to the slope, given the layer of future plaster. With the applied corner you need to spend a straight line on the windowsill, which will be perpendicular to the window plane. Each of the two sides, the corner must be present at one such line. Now it is necessary to draw a line there, which would continue the walls of the walls until it intersects with the first two lines. It turns out two points of intersection. For these two points, you should navigate when cutting the template. It is not at all necessary that the upper solution of the slope is the same as the side. Therefore, it can be done even on the eye.

- There are several ways to set the rule on the vertical. For this, for example, you can put it on the windowsill and put on the plaster. If the window sill at the window is not, then you can screw the usual screws into the wall, use it for the rule as the bottom of the reference point.

- The rule should be led to the wall, set it from the construction level strictly vertically and to deceive the place behind it from the slope. After that, it is necessary again with the help of checking its vertical. To not shifted the rule, the solution must be kneading quite dense.

- While the solution is captured, you can cut the pattern from plywood. At the same time, it is important that the working line of the carved template in the rule necessarily coincided with the third, conducted on the windowsill, line.

- When the solution has already grabbed, you can apply plaster. But before that, the slopes must be projected. When the working surface is projected, with a spatula, we throw the solution "on the plus", while it is necessary to above and below the distance of about 10 centimeters. When the putty is applied, you need to take a template, and movements from the bottom up to remove the excess mixture. In order for the template to pull a smaller number of plaster, should be made from the side to the side of light movements. You need to stretch the template several times, while removing the excess solution every time. When the bulk of excess plaster will be removed, you need to spend a template for another 3-4 times, but this time without movements from side to the side. The same actions will need to repeat from above-down. This will make it possible to remove a noticeable amount of excess mixture from the slope.

- After that, there will be two untreated areas from above and below. These sites should be filled when the main treated plane will already dry. Save the surface usually about two hours, but for now you can soak the second slope of the window. When the first slopes frozen, then the rules should be taken and close the remaining areas with them. If a short rule does not break on the plane of the frame, which remains for more small areas, then you can close them with a spatula or ironing. When the side slopes are finally frozen, then the rules should be removed. To do this, it is enough to knock them stronger. When they are removed, you can see that the plane of the slope does not correspond to the wall plane, i.e. A little speaking. In order to fix this, you can use the edge of a spatula or ironing. It needs to be done as quickly as possible. Not a problem, if somewhere cuts out more than you need. After all, then protective corners will still be installed.

- Now you can switch to the plaster of the upper slope. Perhaps it is more difficult to make it. The complexity is that it is already impossible to set the rule to the solution. In addition, vertical frames will interfere. To begin with, the rule should be fixed on top. This must be done by attaching the sides of the two suspension and they are already hang rule. Thereafter, a solution typically necessary to enclose, while controlling its level. When the solution hardens, typically there will be stand firmly in place. Stucco will have to apply small areas. After applying the mixture to the next portion must wait its pour and fill the next portion of the solution.

- Sometimes the window consists of three sections, and all these sections are at different levels. This is definitely complicated by the task, but does not make it not solved. To solve, you can make two narrow strips from plaster from each side of the slope, and after they are frozen, pull the remaining plane along them.

- In any case, after carrying plaster on all slopes, you will need to take off the rule, unscrew the screws, and then silent the rebier of a spatula or ironing is all unnecessary.

Stuccoing of slopes of doors

Plastering door openings is easier than the window plaster slopes. Video provided after the article, it clearly demonstrates. Consider the process on the example of the entrance door. The first thing you need to do is predict the working surface, determine the solution for slopes and set the rule solution. When working, many actions will be similar to those that you were conducted during window plaster. As a template, you must make a plate with a rectangular neckline. Then you should apply the solution "on the plus" and with the help of the template, remove unnecessary. Next, the steps are almost the same as with the window.

So that there are no questions left to the topic, how to make the slope by plaster, separately it is worth saying about the plaster of direct slopes that happen, for example, in arched openings. These slopes do even easier. To do this, you also need to set two rules on the sides. At the same time, it should be relying on the fact that in the end there should be almost direct angles. Now it is necessary between these two rules to apply the mixture. It should be removed unnecessary by the third rule or if the width allows you to make it back to the opposite side of the smooth.

We put the protective corners

The protective corner is a long steel tape folded in half with a plurality of holes over the entire surface. The mixture will penetrate into these holes during installation, which will give them a good clutch with the working surface. Such corners will allow corners from possible damage during operation. Therefore, they are recommended to be installed on all external angles. In addition, with the help of these devices you can form clear angles.

- Installation of protective corners is made on putty or plaster. Best of all, they sit on putty. The installation order of the corner must be the following.

- First, cut off several corners of the required length. In addition, you need to let the putty. In order to reduce the number of lumps to a minimum, you should do this manually.

- When the corners and the mixture are ready, then you need to apply a mixture with a uniform layer on the inner surface of the corner.

- Next, you should attach a corner to the corner of the wall with a strong pressure. At the same time, the putty should get out of the holes. This mixture must be assembled with a spatula and apply an corner on the outer side.

- Now you need to check the angle for the presence of cracks and bugs using the rule. If there is no, then the following corner should be put in the same way.

- When all corners are installed, you need to walk in one or even two layers of putty. As a result, everything should be smooth.

Some nuances

- To work with slopes from plaster, several important nuances should be known. One of these nuances is that the wall surface must be well moistened. Just moisten the water is not enough. Therefore, so that the splashes fall into all the pores of the wall, you need to use a flying brush or a spacker.

- The solution itself to improve the adhesion to the wall surface must be thrown into the slope. This should be made by sharp and accurate movements. In particular, this concerns the upper horizontal part of the slope.

- To make the solution better on the wall, it is necessary to add plaster to it. If the surface of the wall under the future slope is not a brickwork and has a good grip with a solution, then you do not need to immediately throw the mixture, and you must first ram the solution. It is enough to hold the rule, for example, by the little ones, while removing everything too much and leaving the material for 30 minutes to grab.