Conducting floor insulation is an integral attribute of energy-saving technology. In addition to reducing the cost of heating the premises, the warm floor is comfortable. For the implementation of thermal insulation works are used various materials. One of the most sought-after is polystyrene foam.

Content

Benefits and disadvantages of material

The popularity of expanded polystyrene is due to its excellent technical characteristics. The main ones are:

- low weight;

- environmental friendliness;

- ease of installation;

- resistance to temperature differences;

- long service life (up to 50 years);

- good sound insulation qualities;

- affordable price.

The extruded polystyrene foam for the floor does not absorb soil moisture and resistant to the effects of a chemical and biological environment. This material is not a medium for habitat of fungi and other microorganisms.

Due to the presence of a dense cellular structure, extruded polystyrene foam is able to withstand maximum loads (up to 400 kg / m²). It can even be laid on the gravel layer.

The disadvantages of polystyrene foam small:

- combustion;

- exposure to mechanical damage;

- the ability to dissolve in contact with organic mastic or resin.

Criteria for the choice of polystyrene foam

To purchase high-quality material, it is recommended to visit a specialized store. But this is not enough. When buying polystyrene foam, close attention should be paid to:

- packing goods;

- appearance and smell.

Packaging of thermal insulation material must contain the following information:

- information about the manufacturer;

- list of regulatory documents;

- brand of polystyrene foam;

- recommendations for use;

- technical characteristics of material;

- sizes of sheets.

In appearance, polystyrene foam should be white without different shades. Damage, fragments and peeling granules indicate low quality insulation. According to the structure of the granules should have approximately the same size. High quality polynostilol does not have a sharp smell.

Nuances of installation work

When insulating the floor, the polystyrene type is taken into account. Heat insulation works can be carried out:

- on the soil;

- on the concrete floor;

- on lags.

Warming on the soil

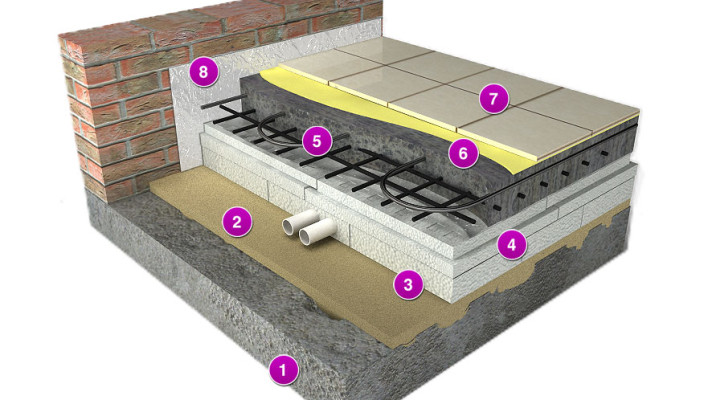

This technology lies in the insulation of sex with polystyrene foam under the tie:

- there is an alignment and tamping of the soil;

- a 10-centimeter gravel layer is poured;

- it is also aligned and trambed;

- capping is made of sand in a small fraction with a layer of 10 cm;

- all empties between gravel are filled out;

- in the entire area of \u200b\u200bthe floor, the waterproofing film is laid;

- the insulation is stacked;

- the joints of the polystyrene foams are sicked with scotch;

- another layer of waterproofing material is laid;

- mounted mounting mesh;

- a concrete screed with a thickness of 4-6 cm is poured.

The feature of the technology is that the soil contact with the floor is occurring. In some cases, groundwater is very close. Thus, the styling of polystyrene solves the problem of the floor waterproofing.

Concrete floor

In many ways, the process of insulation of concrete sex with polystyrene foam is reminded of thermal insulation work on the soil. The only nuance that is worth paying attention is to reduce the height of the room.

The process of thermal insulation of concrete floor by polystyolistol includes such steps:

- cleaning the foundation and elimination of defects;

- applying to the surface of the primer;

- installation of insulation slabs;

- sealing joints and plagged foam slots;

- roofing waterproofing material;

- paul concreting.

You can use another technology. Instead of laying polystyrene foam, its granules are added to the concrete solution:

- the dry cement mixture is poured into the water and stirred a drill with a nozzle-mixer;

- the solution is mixed to the operating state (to sour cream consistency);

- polystyrene granules are added to the solution without stopping the mixing;

- the fill of the screed is made directly on the concrete basis.

The proportions of the concrete solution and the insulation granules can range from 1: 3 to 1: 6. The larger the solution contains the granules, the lower the strength indicator.

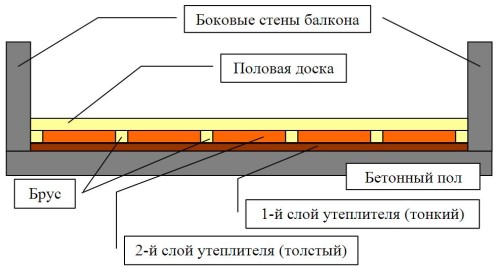

Floor insulation with lags

Warming with extruded polystyrene floor with lags begins with mandatory wood processing with antifungal and moisture-resistant compositions. Thermal insulation works consist of the following steps:

- floating gravel with sand;

- montage Lag.;

- filling with polystyrene fiber space between lags;

- seal all the plaggers of the mounting foam;

- laying the waterproofing film;

- screwing to lags OSB or chipboard boards;

- installation of the finishing flooring.

Useful advice

For high-quality thermal insulation work, close attention is paid to the following points:

- Heating insulation is performed at a temperature of + 5 ° C to + 25ºС.

- It is not recommended to use polystyrene foam for heat insulation in a wooden house. The material is able to delay condensate, which will lead to rotting of wood.

- When using bad dowels that are mounted heat insulating plates, thermal bridges may appear. Through them will go warm.

- For heat insulation, only extruded polystyrene foam is used. The usual material will quickly wet and deteriorate.

- With the insulation of the floor with lags, expanded polystyrene foam of 5 cm thick (heat insulation between floors) is used to 10 cm (insulation of the first floor).

- To close the gaps between thermal insulation material and lags, you can use conventional fiberglass.

Video on the insulation of the floor by polystyolistol: