Today, almost every building, taking into account the climate in our latitudes, needs the presence of heating, despite this, this is a residential private house or a dacha small building, where they live only temporarily. Often, buildings with a cold roof are built to reduce the construction budget. These buildings need additional thermal insulation, which will prevent the exit from the placement of the generated heat obtained from boilers and other heaters. As you know, warm air is able to climb up, so reinforced attention should be paid to the warming of the roof of the house. Next, we consider in detail the method of insulation of the ceiling in a house with a cold roof.

Content

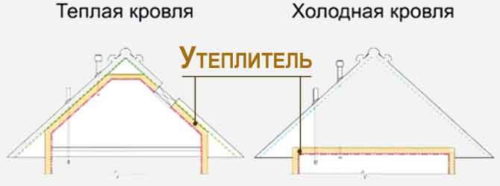

Ceiling insulation in a cold roof house. Differences between the warm and cold roof

The insulation of the ceiling of the roof should be carried out with the conditions for further operation of the construction. In addition, it should be foreseen of the roof (warm or cold), its configuration, features of the rafting system, the presence of a place under the roof for further laying of the heat insulator.

Naturally, the characteristics of the warm roof differ from the features of the cold. Therefore, the choice of the type of roof should be carried out at the stage of building planning.

Of the peculiarities of warm roofs, you can allocate the main:

- In such structures, the skates on both sides are completely insulated. Therefore, it is advisable to build this type of roof in those houses where it is planned to live year-round.

- In addition, such structures are built in the event that the attic floor is built in the building.

- Warm roofs are recommended to be installed only in those houses in which uninterrupted heating throughout the year.

- Such structures have a higher installation cost than cold roofs.

- When constructing the roof of this type, the phased layering of hydro and thermal insulation materials is used.

The specifics of the cold roof are represented by the following moments:

- The structure of this roof differs from the design of a warm roof. It does not insulate the rocks, and the thermal insulating layer is not being erected.

- This design is suitable for premises in which there are interruptions with heating or it is completely absent during the winter period.

- It is used in homes in which there is no attic floor.

- This design has a small weight.

- Suitable for "budget" construction, since the cost of building a cold roof is small.

- Installation of such a design is performed faster and easier than installing a warm roof.

Why is it necessary insulation ceiling of a cold roof

Given all the features of the design, as well as the performance characteristics of cold roofs, their insulation is more expedient to carry out in the ceiling zone. Consider the advantages and justification of the need for a cold ceiling insulation:

- As is known, there are about 30% of all heat loss on the ceiling, because warm air rises up. If we put the thermal insulation layer in the ceiling zone, it will become the main obstacle to the output of heat outward.

- If you pave the thermal insulation layer on the ceiling at home, it will serve as a barrier to enter the heated air from the street in hot summer days. Thus, a comfortable temperature will always be maintained in the house.

- The insulation layer will also become a good heat insulator. So, the house will be less heard noise from the rain, the strong gusts of the wind, etc.

Cold roof ceiling insulation methods

In the building materials market, many options are offered for insulation of a cold roof ceiling in a private house. Therefore, in order to not be confused in the abundance of the available range, heaters should be chosen for the roof in the following criteria:

- Heat conductivity indicators. The smaller these coefficients, the more heat will be stored in the room.

- The thickness of the ceiling insulation. Too thin layers of the insulation will not be able to delay a sufficient amount of warm air indoors.

- Resistance to moisture. Since the installation of the insulation is carried out in the roof zone, it is very important that it has good moisture resistance.

- Duration of service life.

- Environmental purity, safety for tenants. When choosing materials for insulation, the ceiling from the inside is better to give preference to environmentally friendly types of insulation.

- Failure indicators. To cover the ceilings in a private house, it is recommended to use materials that do not support burning.

Often used for the insulation of the ceiling with their own hands the following insulation:

- Sawdles, wood chips, pellets.

- Styrofoam.

- Slag.

- Equouthat.

- Mineral wool.

- Stone wool.

- Ceramzit.

- Polystyrene foam.

- Floors of polyurethane foam.

- Basalt plates.

- Clay.

- Tow.

- Seaweed.

- Plates of glass gambles.

- Comena.

- Needles.

- Straw dried foliage.

- Exceeded moss.

Heat ceiling of cold roof sawdust

This is one of the oldest methods of wood ceiling insulation. This insulation without any problems can be reached in wooded and forest-steppe zones.

The advantages of this material include:

- easily accessibility

- ecology,

- cheap cost

- ease of installation.

The disadvantages of the ceiling insulation of this insulation are:

- High flammability material.

- Little service life of the insulation.

The procedure for insulation of the ceiling sawdust:

- With the help of sawdust, the ceiling of the room is most often insulated (that is, the sex is attic). Initially, the attic beams are stacked by a layer of waterproofing film, which will prevent moisture from entering insulation.

- Next is preparing a solution in which the cement (2 parts) is mixed with wood chips (8-10 parts) and poured with water.

- The half of the attic on the waterproofing film is cooked with the prepared solution. The thickness of the layer must be about 25 cm.

Cold roof ceiling ceiling insulation

This is a classic technique used for a long time. Clay has excellent thermal insulation properties and is natural and environmentally friendly material.

The insulation of the ceiling in a wooden house with clay is carried out in the following order:

- First of all, a layer of waterproofing film is placed in attic beams.

- Next is preparing a mixture of clay and wood chips. For this, 4-6 buckets of clay takes, diluted with water and sawdust is added to the resulting solution. In order to mix such a number of mixture well, it is recommended to use a concrete mixer.

- A layer of clay mixture is placed on the waterproofing film. The thickness of the insulation layer should not be more than 25 cm.

- Then the surface of the layer is recreated.

- After the insulation dries off, the cracks formed again smeared the clay mixture.

Warming Ceiling Cold Roof by algae, reed

Advantages of ceiling insulation in this way:

- Algae and reeds are natural and eco-friendly materials.

- These are safe and hypoallergenic insulation.

- Good thermal insulation characteristics.

- Weak spotlights.

Order order:

- Mates are folded from the cantham or algae, which are supposedly tied with wire or twine.

- The mats are stacked on the ceiling overlap. The thickness of the insulation layer must be approximately 25 cm.

Ceiling insulation with minvati

Mineral wool in the construction and repair of premises is used relatively recently. In a short time of its application, it earned a large number of positive feedback from both the builders and users. The concept of mineral wool can be successfully applied to several materials, depending on which raw materials were used in its manufacture. So, mineral wool makes from:

- Dominal granulated slag.

- Sand.

- Glass battle.

- Basalt fiber.

Glasswater is the oldest of the types of this insulation. Due to its high trauma, it is rarely used in civil engineering, especially if we are talking about internal insulation. Contact with this material due to the presence of thin glass fibers in it can cause skin irritation and mucous membranes, which is not too nice. The main site of the glass gamble is the insulation of pipelines, although, now, in this area, they are trying to move away from it.

For insulation, the attic is the most optimal option is basalt wool. Material from gabbro-basalt fibers has excellent thermal insulation qualities. It is produced both in rolls and in the form of mats, which much simplifies work with him. Unlike slag, which can not be used for internal work, the use of material from basalt for them is permissible. Among the advantages of this insulation, you can also select excellent workability. It just cuts out that allows you to lay it in the most hard-to-reach places.

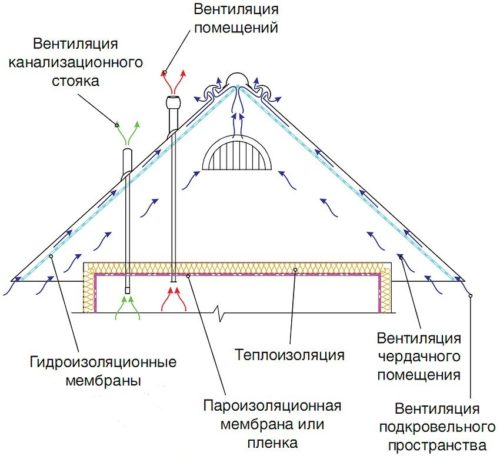

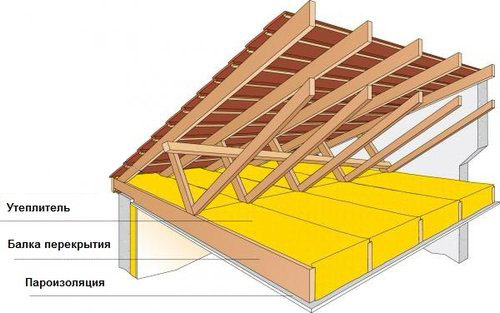

Mineral wool laying on the surface of the ceiling most often spend on the side of the attic. This process is not too complicated and it can be performed with your own hands. The order of work on the insulation of the ceiling Minvata is as follows:

- The first thing to the surface of the attic overlap is stacked by a layer of vapor insulation. As the latter, polyethylene film is most often used. It is stacked between the beams of a mustache at least 100 mm, with subsequent sealing of seams with the help of a tape. With the flooring of the film, it is obligatory to the surface of the walls with a height of at least 150 mm.

- Next is carried out styling the material. It is necessary to do this in such a way as to prevent the presence of cracks between stripes or mats. If the chimney comes out in the attic, it is necessary to withstand the distance between it and the insulation.

- After the end of insulation, the floor is laid over mineral wool. Of course, you can not do this, but in this case it will be impossible to go on it. The most optimal option for these purposes is the boardwalk. The laying of boards in the attic is carried out in such a way that the air clearance is at least 30 mm between them and insulation. This will ensure its ventilation.

Insulation of the attic of a cold roof using foam

The polystyrene foam is one of the most popular materials that are used for insulation of attic rooms. With its excellent thermal insulation, the foam has the most important advantage - low price. Due to the fact that it is not afraid of moisture, you can safely lay the screed on its surface. The only disadvantage of foam is its flammability. At the same time, during burning, it highlights very toxic substances, due to which it is prohibited from which in some countries. The most suitable type of foam for insulation the attic is extruded polystyrene foam. It has the ability to self-effect, as well as increased mechanical strength. The expanded polystyrene was produced in the form of standard plates of various thickness, which significantly facilitates its installation.

Work on the insulation of the roof of the foam is carried out in the following order:

- Hydro and vaporizolation is placed on the surface of the overlap.

- On top of the insulating layers, polystyrene plates are laid out in such a way that there are no cracks. The seams between the plates close with a tape.

- On top of the foam plastic again laid waterproofing.

- The last layer poured a screed. For this process, lighthouses are installed on the surface of the foam, the beacons are established.

Ceramzit for insulation attic

Since clay granules are made from natural clay, it is the most environmentally friendly material, with excellent indicators of thermal insulation. The low weight of the ceramisita made it possible to pour almost any layer of this material, without fear for the state of overlapping. However, it is used only on concrete floors.

Due to the fact that manufacturers produce material of different fractions, you can adjust the density of the layer, and therefore its thermal conductivity.

Works are performed as follows:

- Start work on laying clay from cleaning the surface of the overlap.

- Then the surface is covered with waterproofing.

- Over the waterproofing, the clay layer is fill

- The next step is covered with a layer of clay. Depending on the climatic characteristics of the region, its thickness can vary from 250 to 500 mm. It is recommended to pour a mixture from different clay fractions. In this case, it will be more uniform and have better thermal insulation.

- A screed or boarded floor is styled on top of the ceramisite.