Polyethylene multi-layered pipes are often used for laying water pipes on household sections. Produce pipes in a way without the use of high pressure, so that the pipes become plastic and durable.

Content

Characteristics of Material PND

The abbreviation "PND" is decrypted as low pressure polyethylene. This marking indicates that the pipes were made without the use of high pressure. Suitable for laying water supply water and cold water supply.

From what is the PND pipe:

- several layers, first, it is an internal or crosslinked polyethylene layer. Is formed by crosslinking the edge of the workpiece under the impact of high temperature;

- adhesive: Strong layer, designed to withstand water pressure, so pipes can be installed on country and household plots for irrigation organization, etc.;

- between adhesive layers is a airbag or an oxygen barrier. Pipes can be called durable, but subject to the presence of a protective layer. Then you can perform an installation of external water supply (in the open method);

- the outer layer of polyethylene is a durable layer ensures reliable protection. From the information specified on the front of the pipe, you can learn about the stitching method and the type of pipe (marking: numbers, letters).

Selection of polyethylene pipes

To mount the pipeline by all the rules, you need to start with the selection of polyethylene pipes. There were cases when everything was done correctly, and the pipes began to flow after a couple of years of operation. Although such water pipelines must cope with the loads for several decades. What is the reason? It turns out you need to know how to choose the right tube. There are on sale pipes that are made of plastic waste by secondary production. Such pipes will be cheaper by 2 times, only the benefits of them are not much: the strength is low, and the water flowing from such pipes, "sticks out" the sharp smell of plastics. Hoping that over time the smell will disappear, it is not worth it.

That's why. Before proceeding to the installation of the water supply, it is necessary to figure out and learn how to choose pipes:

- We inspect the pipe: if there is no marking (letters and numbers are missing), there are splashes and stripes, there is a sharp unpleasant smell, they are unsuitable for laying the pipeline. Such materials are used only to supply engineers.

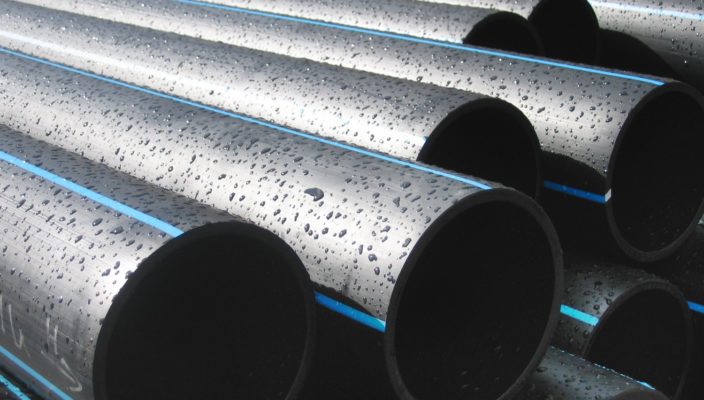

- Polyethylene pipes intended for feeding drinking water are painted only in black, along the top of the pipe runs the blue strip (one or more). The color is saturated, homogeneous, the surface of the pipe is smooth, without dents and bulges. Wall thickness - according to GOST (18599-2001), the diameter of the product should be specified, information about the manufacturer and strength of the product.

- Marking 100 - Durable pipes and dense, withstand high pressure than pipes with PE-80 marking.

Using PND tubes

According to regulations and standards, polyethylene pipes are used:

- for feeding drinking water up to 40 degrees;

- for transporting engineering, up to 40 degrees;

- for gaseous, liquid medium (transportation), provided that the temperature of substances will not be higher than +40 degrees and that the medium, inert to the substance from which the pipes are made;

- for insulation or for laying the electrocable.

In compliance with all rules, polyethylene products will serve about 50 years.

Pros and Technology Connection of PND pipes

The PND pipes intended for the supply of cold water are beneficially different from cast-iron pipes and steel, they are not subject to corrosion, do not change the taste and quality of drinking water.

Pluses PND:

- large service life is about 50 years;

- the affordable price is due to low cost, because for the production of pipes does not need expensive equipment and the purchase of raw materials;

- low thermal conductivity;

- condensate is not formed on the surface;

- pipes are not subject to corrosion;

- pND pipes are plastic, so they can be laid not only in the trench, but also on the surface;

- drawdown of buildings and structures, as well as low temperatures, are not terrible with such pipes;

- installation of water pipes with a closed and open way is carried out in any weather;

- pipes do not pollute the environment, do not distinguish harmful substances;

- the weight is minimal, sold in the bays, which greatly simplifies not only installation, but also transportation.

What are the shortcomings of PND pipes

Each material has not only advantages, but also the cons, about which it is desirable to know before everything is purchased and a plan for mounting the water supply.

Disadvantages:

- with increasing temperature above the permissible norm, the material becomes fusible;

- under the influence of direct sunlight, pipes are faster.

This disadvantage is compensated in this way: a special coating is applied to the surface.

Technology Connection PND

This tool will need this tool:

- hoven for metal or a special tool for cutting polyethylene pipes;

- cone-shaped knife to handle a cut edge;

- if you use fittings, then nothing will be needed, but some wizards advise you to have an adjustable key so that when tightening connections, it is not too tightly clamping the nut. Otherwise, the clips may not withstand and burst or will suffer the gasket-seal. If the nuts are not sufficiently fixed, then the tightness of each joint will suffer.

Compression fittings for PND pipes. FEATURES OF MONTAGE

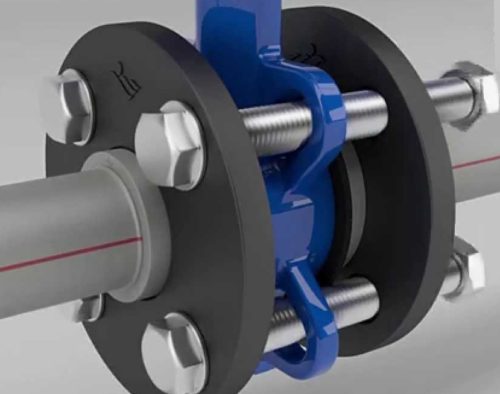

When installing the water supply, do not do without special compounds or fittings. They can be straight to combine the tubes and transition to each other when you need to connect different diameter pipes. In addition, the fittings will help connect the pipeline in several directions, make the desired bending or angle, reduce or vice versa, increase the diameter of the pipes.

Installation of pipelines with fittings is performed in several stages. The work is not complicated, so even the newcomer will cope, the availability of special tools will not need.

How to perform installation:

- Prepare pipes, count in advance how much the meters of the pipe for laying the pipeline.

- Fittings unscrew 1-2 times.

- Marking on the working surface, lubricate the place of docking with soap solution (can be simply ordinary water).

- Enter the pipe into the fastener to the mark. Make sure that the pipe segment rests on the ring. To achieve this, you need to attach a little more power.

- If at this stage it is good not to try, then the tightness of the compound will not be 100%.

- Tighten the nut until it stops so that there are no free turns on the thread.

Flange compounds for PND pipes are one of the ways of mounting the water pipeline from PND pipes, in which if necessary, the assembled node can be disassembled. The flange compound is used to dock adjusting and shut-off valves. For installation, you will need a polyethylene tube, a metal sleeve and a free flange.

To obtain a reliable pipe connection, another method is used: an in-view or welded connection for PND pipes.

Performed by 2 ways:

- Shake into the joint.

- Connection with an electric coupling.

Welding jack is performed using a special welding machine. With a big desire, you can master the docking technique to pave the water supply on your own, without attracting specialists.

How to connect the joints of the joint into the joint with the help of a welding machine:

- Pipe ends (provided that the pipe diameter exceeds 50 mm) needs to be fixed in special clips of the welding machine.

- Test to the location of the heating plate.

- Wait until the plastic will warm up and reaches the melting point.

- After that, you need to remove the stove, and the pipes can immediately dock with each other, applying efforts.

- Wait a few seconds until the seams are cooled, after which you can remove the clips and remove the device.

What is important with the method:

- Materials are used only by one diameter, otherwise nothing will happen.

- Wall thickness - no more than 5 mm.

- It is possible to work outdoors at a temperature not lower, +15 degrees and no higher than 45 degrees.

- The welding machine runs from the network, it does not consume a lot of energy, so this method can be bolded to name the most economical. Even despite the fact that the cost of the device is very high, in order to independently perform installation of the water supply system, the device can be leased.

Hydraulic Testing PND Pipes

Any pipeline, even performed by experienced specialists, must be experienced. The first launch is the most responsible, it will show all weak points.

Proceedings:

- External inspection of the water supply, removal from the air system.

- Inspection is carried out after the completion of the installation.

- Before you begin work, you need to clean the cavity of the pipes from dirt, open the valves to lower the air.

- Drain of water to install at the bottom points (drainage).

- Connect pressure gauges on both sides.

- Connect the pipeline to the water supply or the nanos to create pressure and fill the system.

- With closed air, it is necessary to smoothly raise pressure, to withstand for a quarter of an hour. In order for the test to be successful, water should be gradually pumping to stabilize the pressure.

- After that, to reduce the pressure to the working standard, leave half an hour. During this time, it is necessary to have time to perform a visual inspection of the pipeline, especially pay attention to all joints.

- The plumbing stood the test if leaks and breakdowns of the connecting elements were not detected.

Errors when installing polyethylene pipes

Installation of PND pipes - the task is not difficult, it is difficult to make a mistake and do something wrong, but errors are no exception.

Often allowable errors:

- if different pipes are used. Newbies may not disassemble and acquire different pipes. And each type of plastic has its own norms, so the tightness at the junction site can be broken. Result: leaks and cracks at the connection site;

- strong tightening of nuts can provoke the appearance of microcracks. With a primary inspection of the finished work, they will not show themselves in any way, but under pressure the crack can increase and then water will be leaked;

- a weak tightening, as well as strong - also not good;

- uneven dust edges: if you use the welding machine, then you need to customize the edges. Used for these purposes a carrier.

Video instructions on the installation of PND pipes do it yourself: