The final stage when working with plasterboard is sealing seams. Despite the fact that this process is not difficult, it should be considered with all seriousness. In this case, after some time, cracks will appear on the trimmed surface. About how and what to close the seams in the drywall, we will now take a conversation.

Content

Conditions for work

In order for the sealing of the seams of plasterboard, it is necessary to comply with a number of requirements. In particular, special attention is paid to the temperature and humid regime in the room:

- the minimum temperature should be + 10ºС;

- there should be no drafts;

- for 3-4 days after repair, the temperature should be approximately the same;

- seaming seams is carried out after all plastering and concrete works.

The whole plastered surface should dry. The presence of high humidity in the room will make it difficult for the process of normal pouring of putty. And this will lead to the deformation of the seams.

Before closeing the seams between the sheets of drywall, it is necessary to check the correctness of the fastening of the material on all areas. If the plasterboard is poorly fixed, it is fraught with rapid destruction of putty in places of connecting sheets.

It is necessarily accumulated in the drywall all the tapping screws. Their heads should not perform above the surface of the material, because they will interfere with the finish finish.

Seam sealing materials

Now let's talk about how to put the seams of drywall. To fulfill this work, we will need two main material:

- paper reinforcing tape;

- putty.

Tape for sealing

Paper tape for drywall seams is the most optimal option for imposing joints. Sheetrock Joint Paper Tape tape uses in high demand. Standard dimensions of one roll are:

- length - 76 m;

- width - 5.25 cm.

Sheetrock Joint Paper Tape belt has the following features:

- increased strength;

- not stretching;

- stacked without folds;

- the possibility of centered folds, which simplifies the trim of the corners;

- durable compound of plasterboard sheets;

- maximum prevention of discontinuities.

Due to the fact that the ribbon for seammalls of the Sheetrock Joint Paper Tape is very thin, it can be carried out using a conventional putty. Moreover, the sealing of the joints can be made without the removal of the chamfer of horizontal seams, and the sheets are mounted online.

Putclone for sealing

Putty for seams of plasterboard can be used in the finished form. But it is best to get a dry mix, since it can be kept longer. Yes, and the cost of dry putty is significantly lower. In quality, it does not differ from the finished mixtures.

The only nuance is mandatory compliance with the technology of making a solution. To do this, you should clearly adhere to the instruction that is always attached to the corporate products.

The basis for the manufacture of putty is one of the three components:

- cement;

- gypsum;

- polymers.

Cement putty is resistant to the impact of a wet environment. But sometimes the surface, decorated with this material, is covered by microcracks.

Putty, based on the manufacture of which lies plaster, very susceptible to moisture drops. Not used in rooms with high humidity.

The best material is a polymer putty, which absorbed the best characteristics of cement and gypsum putty.

Among the diversity of compositions, the most appropriate options for shtocking of seams between plasterboard are the products of the company "Knauf":

- Fugenfuller GW;

- Fugenfuller hydro (seams of moisture-resistant drywall);

- Uniflotte.

The putty Knauf Uniflotte is quite expensive. But the result will not make yourself wait. According to the strength indicators, this material is significantly superior to similar products.

If putty work is planned to be made immediately, it is better to use the finished mixture. The best option is to put Sheetrock.

Opening seams

Plasterboard sheets are produced with different longitudinal edges. The most acceptable solution is the use of material with edges that have semicircular refinements. Thanks to this edge, the maximum deep contact of the sheet with a putty, and in the end the perfect surface is obtained.

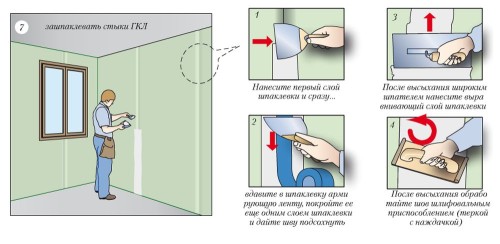

The process of the joints of the seams of plasterboard consists of the following main steps:

- surface preparation;

- applying the first layer of putty;

- laying reinforcing tape;

- applying the finishing layer of putty;

- grinding surface.

The surface preparation is to remove dust. Putchal must stick to the surface without any problems. Dust removal is carried out using a wet rag.

Filling seams with putty is carried out by a spatula. The application of the mixture occurs in the transverse direction from the seam. The procedure is carried out along the entire length of the joint. Excess putty may be present only in the extreme part of the seam.

Sheetrock reinforcing ribbon laying is done in such a way that a spacure layer in 0.5-0.7 mm remains under it. To facilitate the process of laying the tape, it is necessary to dilute the cooked putty to dilute with a small amount of water.

The tape is interpreted into putty throughout the seam. The central part of the internal bending of the tape is placed in the center of the joint between the sheets of plasterboard. This work is carried out with a spatula, when pressing an acute angle of which an excess solution is removed. The tape is completely covered with putty.

After drying, the ribbon is applied to the second layer of putty. Horizontal joints are covered with a thicker layer of material. The second layer of putty should also dry. After that, you can engage in grinding of seams by sandpaper.

Video on the sealing of gypsum cabarton seams: