Creation of durable and reliable waterproofing is a very important and responsible process during any construction. To solve this task, many options for suitable materials are presented on the market. The most effective among the entire line of proposals are those species that relate to the category of liquid waterproofing. To find out all the advantages of this method, quickly decide on the appropriate type of material and use technology, carefully review the entire information outlined below.

Content

The advantages of using a liquid waterproofing

The materials of this group, like no other types of waterproofing, are distinguished by a very long list of advantages:

- High adhesion indicators regardless of the type of base.

- The ability to correct all surface defects are cracks, irregularities and other defects.

- A variety of application methods allows you to make an optimal solution, depending on the scope of work, level of professional skills and design features.

- Durability of operation.

- Integrity and seamlessness of the formed coating.

- Excellent moisture-repellent performance.

- Resistance to any other type of negative impact, both natural origin and artificial.

- Good frost resistance excludes any use limitations depending on climatic conditions.

- The versatility of use is also suitable for processing internal surfaces and for external bases.

- Does not block air circulation, which is very important when using certain types of basic building materials.

- Environmental safety application - even contact with drinking water is allowed.

Types of materials

Given the popularity of this type of waterproofing, manufacturers regularly release new varieties, improving existing ones.

The following types are most in demand:

- liquid glass;

- liquid rubber.

Important! Please note that the use of materials of these categories allows you to create waterproofing any room as quickly and without difficulties.

What are the foundations you can apply liquid waterproofing?

As we have already mentioned, liquid waterproofing, the price of which varies depending on the component composition and volume of the phasing of the solution, is characterized by the universality of the application. This applies not only to the possibilities to handle various surfaces, regardless of their location, but also to the source base materials.

We note only some of the most popular species that are perfectly combined with liquid waterproofing:

- ruberoid;

- gypsum bloks;

- natural wood and various modifications of sawn timber;

- concrete;

- metal.

Important! Please note that when using bitumen or glass-based solutions, the specific specifications of some species, for example, rubberoid are significantly increased.

Features of the use of liquid rubber

In order to more clearly represent the same type of liquid waterproofing to give preference, we give the advantages and disadvantages of each, as well as note the main directions of more rational use.

Advantages

Of all the above advantages, characteristic of all liquid compositions of this purpose, we note those that are favorably distinguished by liquid rubber for waterproofing:

- The absence of toxic impurities in the composition.

- Elasticity of the coating.

- Simplicity of application.

- No need for additional preparation of the solution.

- When using cold compositions - fire safety.

- Durability - the service life of the hydroelectric coating based on rubber varies depending on the characteristics of the component composition, in some cases it reaches 50 years.

Areas of use

Most often, waterproofing of liquid rubber is carried out when arranged:

- pipelines;

- roofing;

- basements;

- foundations.

Important! Please note that it is permissible to use this material not only for initial construction work in the formation of the design, but also in the process of updating or repair.

Preparation of Liquid Rubber

Preparation of the solution on the basis of rubber depends on the type of composition. In this regard, there are two main types:

- cold drawing;

- hot.

Important! With no special skills, give preference to the waterproofing of the first type, since the procedure is more straightforward. In the case of hot compositions necessarily follow the manufacturer's instructions with regard to heating time and the required temperature, otherwise - will not achieve the desired effect, and the frozen layer will not respond to the above specifications.

Flow material

Determine the intended consumption is sufficiently simple - this indicator necessarily indicates each pack. If there are no such data, stick to the standard solution - 1 kg by 3.5-4 m2 of the area when applied to 2 layers.

Important! This indicator may vary depending on the selected application technology, for example, with manual processing with a hot solution, the flow rate will be slightly higher. Therefore, when buying, leave a small gap - buy a number, percent of 10% more than it is supposed to be used.

Waterproofing features with liquid glass

The compositions of this species are mixtures based on the following components:

The advantages of waterproofing with liquid glass

The most significant advantages are represented by such factors:

- improving the firmness of the foundation;

- excellent mechanical resistance;

- acceleration of the draft projects;

- reducing the cost of construction;

- penetration of the part of the solution into the thickness of the base;

- filling with crystals of even the smallest crack;

- the ability to increase not only a moisture-capacity property, but also the fireproof of various bases.

Important! If we decided to use the liquid glass, and not another type of moisture-repellent material, please note that all coating functions are saved at a target level for no more than 5 years, after which it will be updated.

Areas of use

The most suitable directions for the use of solutions of this type are represented by the following types of work:

- strengthening the soil of different types;

- additive to the base solution during monolithic construction;

- application as one of the components of the plastering mixture to increase its strength;

- the creation of waterproofing walls in residential premises;

- registration of the moisture-repellent layer during the construction of a well or drain pit;

- performing a screed of floors, walls, ceilings;

- treatment of surfaces of bathrooms and pools.

Important! It is appropriate to liquid waterproofing the foundation using liquid glass on areas with a high level of groundwater location and redundant dampness when building heavy soil. When used as a refractory coating, finishing fireplaces, furnaces and boiler rooms are allowed.

Methods of application

There are two main applications of liquid glass:

- in pure form;

- as one of the components of the main building material.

Important! Pick up the appropriate method based on the direction of the necessary work.

How to make a solution with liquid glass?

Browse the proposed recipes for the preparation of solutions for waterproofing from liquid glass to specific construction objectives. Select one that perfectly meets your requirements:

- Solution for primer. To get the composition that is easy to perform this job, mix the following ingredients:

Important! Initially, prepare a pure cement solution, then add water to it. Determine the correctness of the solution by the speed of its frozen - if it is easy to rejuvenate the surfaces before hardening the mass, then the proportions are sustained.

- Solution for waterproofing wells. To solve this problem, mix such materials:

Important! The principle of application is as follows:

- initially, wake the surface only with liquid glass;

- apply the prepared solution to the next layer.

- Mix for wood protection. Preparation of such a solution as simple as possible:

- water - 1 part;

- liquid glass - 1 part.

Important! Walls made of concrete or plastered with cement-sandy mortar, it is better not to smear with such a means. They are covered in a kind of protective film, which is very slippery and further finishing in the form of putty and painting becomes almost impossible.

- Blend for filling concrete. To carry out monolithic construction with elevated technical characteristics, when preparing a concrete solution, add liquid glass in accordance with one of the proposed proportions:

- 72 liters of glass per 1 m3 concrete M-400;

- 1 piece of glass on 10 pieces of concrete.

Important! If waterproofing is necessary in addition to the treated surface to give fire resistance, prepare a solution of the following recipe:

How to calculate the flow rate of liquid glass?

The average flow of liquid glass corresponds to 200-300g / m2 treated surface.

Important! Determine more accurate data, taking into account the proportion of a particular prescription, the type of surface to be treated and the extent of the area under the waterproofing.

Methods for applying a liquid waterproofing

It distinguishes the materials of this type of application a variety of technologies:

General recommendations for the implementation of the liquid waterproofing

No matter which type of material do you prefer when performing work, adhere to the following requirements:

- Air temperature at least 5C.

- Should not be applied when processing the outer surfaces, if during the next 24 hours is expected freezing.

- Exclude waterproofing formation, if the base is covered with frost or ice.

- When decorating horizontal surfaces with pre-wetting is impossible to prevent the formation of puddles.

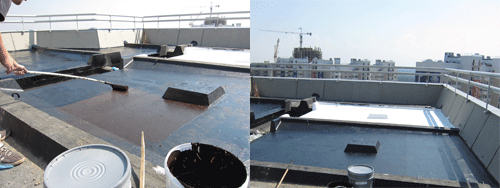

The technology of self-leveling coating method

The optimal solution of such technology - liquid waterproofing floor or a flat roof.

Execution procedures carried out in the following sequence:

- Remove old coating for repair reconstruction.

- Collect all the garbage.

- Strip the surface with a wire brush.

- Prime the base bitumen emulsion, a layer thickness of not more than 2 mm.

- Wait until seizure occurs solution with a base.

- Pour the liquid rubber or a solution to the glass on the surface layer of 2-3 mm.

- Smooth out the solution.

- Make technical pause for drying.

Important! The drying time is usually specified by the manufacturer on the packaging. If such information is not provided, guided on the exterior waterproofing covering, but at least 5 minutes and preferably stand for 2-3 hours.

- Fill 2 layer.

- Wait at least 2 days prior to the continuation of the construction.

Instructions Paint waterproofing method

This technology is ideal for a number of works on the preparation of walls and the foundation in the case when the surface area is small.

Important! The main advantage of waterproofing by staining is the lack of the need to use additional equipment, the cost of which is not always available for a private consumer.

Progress:

- Purify the base in the same way as described in the instructions above.

- Apply a bitumen emulsion or another type of primer with a layer of 1-2 mm.

Important! If you use liquid rubber, prepare the primer solution yourself. To do this, divert the main material with water in the percentage proportion of 70/30.

- Write out 1 hour to reduce the solution.

- Apply neatly the main layer of waterproofing using a roller or brush.

Important! Take a layer of 2-3 mm.

- Cross the mass on the surface.

- Make a technical pause again and create the following layer of the same thickness if necessary.

- Wait for the full pouring of waterproofing, after which you follow further finish.

Important! Review the video example of creating a well-insulation of a well using liquid glass according to this technology.

Instructions for waterproofing by sprayed method

This method is an excellent solution in the processing of vertical surfaces, hard-to-reach horizontal floors, such as ceiling, and at a large scale of construction. The main advantage is the rate of application, but special technical equipment will be required.

- Perform a scope of the ground in accordance with the standard rules.

- Connect a special sprayer device to capacities with liquid waterproofing and hardener.

Important! As the main substance that accelerates the frozen of the coating, the calcium chloride and water chloride solution is most often used.

- Spray substances in the desired direction.

- Adhere to the norm in 2-3 mm when forming a layer.

Important! Given the features of the use of liquid waterproofing according to this technology, reduce the subsequent period of the technical break for drying to 2-3 hours.

- Review the video example of a flat roof processing to clearly understand the principle of waterproofing this method.

Conclusion

Regardless of what kind of type of liquid waterproofing, you preferred, be sure to follow all the rules of use, meaning in the instructions for the solution and described in this article. Only with this approach, you will really be able to create a reliable coating with a long period of operation, and accordingly, and prevent the destruction of the constructed design.