The arrangement of the garden or the local area is difficult to imagine without garden furniture. Tables, benches, canopies and even sun loungers will make holidays in the garden behind the house comfortable. Currently, in building stores, you can find a large number of different garden furniture for every taste and wallet: from cheap plastic models, to elite models with elements of artistic forging and expensive tree species.

Content

One of the most important elements of garden furniture is a bench. It is always nice to sit down in the shade of the trees and read the favorite book in the fresh air. If the funds for the purchase of a garden bench is missing, it can be done on its own. This requires only the minimum skills to work with woodworking tools, time and desire. If this is available, you can safely buy material and proceed to work. As a result, you can not only save money, but also get an absolutely original product that will be pride. On how to make a bench outdoor with your own hands - hereinafter.

Characteristics and design of benches

The appearance of the bench practically does not change for several years. However, with the advent of new materials, some of them begin to be successfully used in the manufacture of these elements of garden design. This is especially true for the production of supports, since it is precisely the main load. So, for this can be used steel. Steel pipes of different sections are required, which are connected to each other by welding. Often in the design with such supports, the benches use various wrought details. Due to the fact that the pipes have a different shape, you can create quite interesting design structures. In addition, their cost is quite acceptable. It is worth saying that with constant contact with the environment, steel supports are rapidly wear out. However, this problem is completely solved with the help of special stores that protect the metal from rust and other effects of the external environment.

Popores can be cast iron. They are rightfully considered the most severe and durable. Melted cast iron is quite plastic, which allows you to create the most bizarre forms. Such supports are often used in various public places, for example, in parks. Claws with cast-iron supports are distinguished by their strength and durability. But at the same time their cost is quite large. The poor-quality cast iron will cost cheaper, but he will not be able to "boast" all the most advantages.

Benches are still made with concrete supports. They have a not very attractive appearance, while they are durable. At the same time, they are relatively cheap. It is also believed that the bench on such supports is distinguished by a massiveness that is not always true. So, for example, the option of the bench, the basis of which constitutes concrete rods, is quite unusually.

As a support for the bench is often used natural stone, and in particular, granite. Such structures serve long enough. Due to the peculiarities of working on a stone at the supports from this material there is no greater diversity. The disadvantages include the high cost of the material itself. It is worth saying that not only supports can be made from the stone, but also the benches.

Bench supports can be made of aluminum. They are good, first of all, by the fact that they do not rust. In addition, they are pretty light. Due to the cost of the material of the shop with such supports, it is quite expensive. So that the data benches are more reliable, they are fixed with anchor attachments.

Frequently often, especially when the bench is done with your own hands, her supports are made of wood. Wood itself is an affordable material, but it requires periodic care. If you do not follow wooden supports, then the process of rotting and the development of fungus can begin.

Choosing a place to install a bench with a back

Before starting work on drawing up a sketch of a garden bench, you need to think about where it will be installed. Garden designers give their advice on what kind of benches is suitable for a specific garden.

Covan from iron shop will become an excellent element for an old garden with large branched trees. But in the young garden, a light bench in a romantic style will be most organically. After placing a couple of such beams near the alpine slide or a decorative pond, you can make an excellent place to stay. It will be pleased to spend time after a difficult week.

The garden bench must be placed in such a way that it is a pleasant eye look from it. Do not place a bench so that the view of a neighborhood, a garage or other economic buildings to be opened out of it. It is better to put it in the garden, near the playground, an artificial pond, or in the front entrance.

If there are a bed in the indention plot, it is advisable to place a bench next to them. Then, after hard work, in case of fatigue, it will be possible to relax a bit. In this case, it is better to put it in the shade. If there is no natural shadow on the site, we have to consider the option with the construction of a canopy, because the sun is unlikely to rest on the scorching sun.

When choosing a place of installation of a garden bench, you must give preference to where there is a solid coating: paving slaves, asphalt, etc. In this case, it will be comfortable to relax and after heavy rain.

Preparation for the manufacture of street benches with its own hands

After the choice of the place of installation of the bench is made, you need to start working on its manufacture. Initially, it is necessary to make a sketch of the future product. This will help determine the amount of material necessary for work, as well as plan the order of work.

Ready projects of benches There are a large number. However, as a rule, they are manufactured according to standard dimensions that are suitable for an adult middle-sized person. If these indicators are covered, then they are as follows:

- Standard bench's length (seating width) - 1.5 m.

- Seat width - up to 550 mm.

- Seat height - up to 500 mm.

- Seat height - up to 500 mm.

With such sizes, a person with an increase of 1.50 - 1.90 will be very comfortable to use this bench. The seat benches should be located under a slight bias. Its edge should be slightly higher than the back. On such a seat, it will be more comfortable to sit, rather than in direct. However, if the angle between the back and seat is too small, it will not be too comfortable from such a bench.

When planning the manufacture of a bench with a back, namely such an option is significantly preferable, it is necessary to immediately think about how it will be attached to the seat. Also, depending on whether the portable bench will be or not, the feet configuration is planned.

Based on the prepared sketch, you can calculate the required amount of materials. As a rule, business waste has been used for the manufacture of garden benches. Usually after the construction of a house or other structures will always be a couple of extra nails, boards or bars.

It will be guaranteed from the tool:

- Electrolovka. For the absence of the latter, the usual wooden hacksaw is formed, but it will be possible to forget about intricate figures, as they can be filled with manually - pleasure below average.

- Electrolake. It will be very useful if the raw board will be used for the manufacture of the bench.

- Set of chisels. Be sure to make sure that they are sharpened properly.

- Drill, screwdriver.

- Hammer, screwdriver, pliers, roulette, square, pencil.

Simple project street bench do it yourself

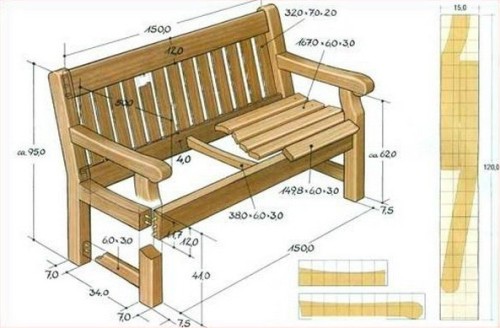

For the manufacture of this model, a 40 mm thick boards will be needed, which will contribute to sufficient stiffness of the structure. The length of the product will be 1.5 m, which is enough for comfortable placement on it three people. The standard boards length is approximately 6 m, so there will be two boards for the manufacture of such a shop. To transport them without any problems in a passenger car, the boards are better cut on the dimensional lengths - 1.5 m.

The seat will be made of 3 boards with a mandatory gap between them. This will ensure the removal of excess moisture at atmospheric precipitation. The same applies to the back of the bench.

For greater comfort, the angle of inclination of the back will be 18 °.

The whole design will stand for 4 legs, while the latter will perform the role of support for the back. Between the legs will be fastened with transverse boards. To give them extra hardness.

Boards are saw, according to the sketch, on the following lengths:

- 5 segments of 1.5 m.

- 2 segments of 0.36 m.

- 2 segments of 0.72 m.

- 2 segments of 0.52 m.

The last segments are subsequently cut along the bars to be used as hardness.

Sections of 720 mm will be cut at an angle to become a support for the back.

After cutting boards on dimensional lengths, it is necessary to fool them to get rid of roughness and sowing. To do this, it is better to use the electrolovka. In comparison with the hand tool, it will not only facilitate the work, but will make it much more accurate. It is advisable to take off chamfer from sharp edges so that the product has not only a beautiful appearance, but also did not cause injury.

At the end of the work, all wooden parts should be treated with special means so that it does not appear mold. In addition, it is recommended to cover them with varnish. Wood after processing is not exposed to moisture, longer serves and long time retains a good appearance.

Metal street bench

A fundamentally project of a metal bench is not too different from the wooden. The only difference is that as a framework of the frame will be a 25x25 mm corner.

For the manufacture of the rear legs, which will be support for the back, it is necessary to cut a corner at a certain angle. To do this, a piece of steel is cut out of one of the shelves, the corner is bent, and the resulting seam is brewed. In the same way they make a second leg. Then connect the front and rear legs with one or two segments of angle with welding, while getting the supporting structures of the bench. The last step will be the installation of seat and back boards. Metal parts are primarily ground, and then coated with two layers of enamel.

Metal benches due to their greater weight are usually done stationary, because it is pretty hard to transfer them from place to place. Although they have a huge margin of safety, in comparison with wooden models, their manufacture requires welding skills and special equipment.