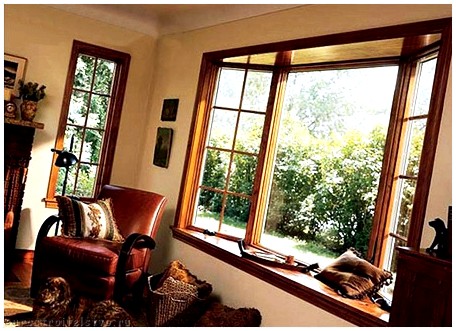

Today, windows made of wood are not tribute to fashion, but the vital necessity of each person. They are products that are perfectly harmonized almost with any kind of furniture, floors, doors and interior, thereby creating a feeling of warmth and comfort.

Content

Advantages of installing wooden windows

The main advantage of wooden windows is that their profile is much warmer plastic. A tree is a fairly bad heat conductor, while its natural porosity allows the design to change its geometric parameters, without bringing the integrity of the frame.

Also produced from the window of the window are characterized by the best operational properties. They have excellent sound insulation, and the profile is able to extinguish the occurrence of ordinary noise and resonant sound waves.

Another positive property of this type of windows can be called maintainability, since they can easily be eliminated very noticeable scratches. At the same time, the wood has proven itself well in our climate conditions, and if it is necessary to care for her, it will last for a long time.

The wooden window is an environmentally friendly product, which, unlike plastic, does not secrete harmful substances and does not contain electrostatics. It has increased strength, high dust protection characteristics and low thermal conductivity.

The only disadvantage of such windows is the need to regularly update the coverage, namely 1 time in 5 years.

Thus, the basic advantages of wooden windows include the following:

- they have a low thermal conductivity;

- eco-friendly;

- they can be painted, soaked with special substances that protect the surface and primitive;

- they are combined with any type of interior;

- have excellent strength with relatively low weight;

- repairable;

- provide the right air exchange;

- create good telo and sound insulation;

- have high frost resistance and low temperature expansion coefficient.

At the same time, good sound insulation of this window is achieved due to:

- the possibility of adjusting the thickness of airspace;

- installation of the desired amount of glasses that have an optimal thickness;

- the density of the gun.

Types of wooden windows

Depending on the purpose and location of the window, created from wood can have a variety of components, fixing mechanism and form:

1. Windows that are opening in both directions.

2. Windows having a rotary, swivel-folding and folding mechanism.

3. Multi-window windows and windows that have deaf and opening flaps.

Wooden windows with their own hands

To make a wooden window, you need to be patient and a special tool, because such work implies a time-consuming, but not very complex process.

Stages of manufacturing wooden windows:

Choice of building materials

With independent manufacture of a wooden window, the material is the most important. If you do the wrong choice, then in the future it is possible to form problems such as the storage and shrinkage of the product. Specialists recommend applying glued, not a solid board and a bar. Such a frame will not be silent and will not swell, and it will not lead it. In the process of acquisition, please note that the glued bar has been carefully succeeded.

Window design

Manufacture of boxes

You can make the window box of standard parameters from the boards having a cross section of 5 × 15 cm. For a larger product, it is necessary to select a large cross section to ensure the stiffness of the structure.

Progress:

- for the construction of the window box, you should take an exceptionally stranded and dry board. On it, with the help of the electrolack, the grooves are 1.5 cm in depth and 13 meters wide so that the profile has a M-shape. Such a comb provides increased tightness of the finished product;

- then the board should be made on 4 parts and secure them with each other with a spike.

If you are engaged in the manufacture of the window yourself, it is better to use the simplest connection, namely, on the blackboard, which will be horizontally, is peeping a spike, and on a blackboard that will adjust it - the groove. To accurately and correctly fulfill such work, we recommend using a manual milling or a chisel with a hammer.

Upon completion of the work with the board, the location of fixation is lubricated with carpentry glue, and only then the box is going. When the glue dries, the window box is considered ready.

Recommendations:

- for high-quality attachment on the corners of the box, you should wear a metal corner;

- for tougher fixation in the end of the connection, a wooden pin is mounted in a specially drilled hole;

- all items must be connected at an angle of 90 °.

Making a window frame

The frame can be made of glued timber having a cross section of 5 × 5 cm. For the window, you can apply boards with a smaller cross section.

The principle of connecting frame parts is the same as when creating a box. However, the installation of a wooden pint and the use of a metal corner is a mandatory point.

This is due to the fact that the strictest demands are presented to the window frame than to the box.

After the profile is made, the electric branches or the mill should cut the board on the workpiece. Next, they need to prepare a spike connection.

Now the window frame can be collected and covered with oil. Be sure to use metal corners.

After mounting the frame, it is necessary to install glass and fix them with the help of the strokes that are also covered with olphis.

The finished window frame with inserted glasses can be painted or left as it is. Of course, if you apply Olif, it advantageously emphasize the structure of the tree, but the use of oil paint is the preferred method.

Installation of a wooden window

Installation of windows made of wood requires compliance with the following principles:

- initially, it is necessary to determine the depth of the landing of the window in the opening. Only in this case you will eliminate the formation of condensate between the frames;

- it is more technically convenient to install the window by applying the mounting block;

- parameters of openings should exceed the size of the finished box by 1-2 cm, and below 5-6 cm;

- each angle of the opening must correspond to 90 °, and the difference between the lengths of diagonals should not be greater than 1 cm;

- the surface of the window opening should be smooth.

Preliminary preparation:

- follow the position of the finished product in the window opening;

- apply the sealant on its lower part;

- on top of it rush seal;

- then install the window block frame;

- check the level of the exhibited product;

- squeeze the frame with a peg.

In the process of installing wooden windows, mounting special systems, construction dowels and screws are the main elements of fasteners. The distance between them should be about 80 cm. Invalid fixation of window blocks with the use of sealants alone, glue, mounting foam or construction nails.

In the event that you create the installation of a new window, the design of the adjacent angles should stop the occurrence of cold bridges that contribute to the formation of condensate.

Progress:

- initially, you should drill a profile to the window opening, and then the robe itself;

- in the opening insert a dowel and screw the window to the frame;

- further on the hinges and loops we put the windows sash;

- sealing the design;

- when the block is fixed, blew all the slots by mounting foam;

- when it hardens, the surplus will need to be cut off, and the cuts to insulate.

After you installed, fixed and sealed the window unit, it is necessary to produce the process of adjusting the sash.

Wooden windows with your hands video:

And GHDE in them a fortie?! Fortochka K, ae?! And the fortage is the main part in the window !!! Check that it is easy, make two types of windows, alone with the window, others on the contrary without it, and place an ad in the newspaper, that the windows are sold like without a window, and on the contrary, having it, and on the contrary, And without it, for the equality of these verbal "components". And look further which of these types of windows of windows that are with the window, or which without it, will be more likely to be in demand from buyers, and you will see that windows with the window will use the buyers with great demand than windows without a window because if it were not so, then all the windows would always be made by people then without forces, but for some reason, these vents in the windows are made, and they made, people, shaking on this extra costs , and time !!!

Fortochka is like a mini window in the window, and she needs less strength to spend on her discovery, and in order to be at the opening, the house was ventilated, and it would be uncooled at the same time with drafts and cold air, and people living in it because the size of the window is small, unlike the size of the entire window, and it is located in the upper part of the window than drafts, even if they are through the window and fall into the house, do not blown directly in their input, residents of this house, located in its inner space below the level of the location of this window in the window of their dwelling !!! Thank you, and I wish you happiness !!!

But I also will also tell you how to reduce the hitting of joints from the window in their direction directed towards the tenants of the house than to save them more from the cold. It is necessary in each window of the window to be made on one window, but the width of each of them, which will be twice as smaller than the width of modern vents, although they will match them along their length, and at the same time, make these thinner in their thickness Footings dropped by their direction vertically-diagano in the direction from top to bottom !!!

Here is Vladislav, I completely agree with you. But I am looking for windows with the windows and nowhere can I find normal ... very sorry ...

I do not see the point of steam. Retail factory that makes windows made of wood, sells for small firms ready profile for those who make windows on the start system and even cuts in size and makes a spike groove. Schip-pump turned out to be reliable. Seam does not crack over time. I have half a year as closed my workshop sold all the machines. I wanted to first close due to the crisis, then just dissolved the people, everything sold the machines. But orders come on average Popo 2-3 windows per week. Once unluckled an order for a cottage in 42 windows. Made one with one assistant in 2 weeks in an ordinary garage. I decided first to keep the start of the TBM start system, but there are mad prices for a profiled bar and buy equipment again. The face is constantly taking when he hears that I need to do with 2 windows accessories. Then the running on managers begins which they do not understand what they sell. I hit Yandex and found the office in Ulyanovsk, she has a warehouse in 26 cities that offers ready-made sets for self-assembly offers small firms. Delivered for 3 days and is not expensive. Buying ready turned out to be easier than to contain from 10 windows per month work and shop. Now I pick it up in the workshop 20 m.kv or rather, it's just a warm garage. A week is obtained by 5-6 windows do not tighten himself. Profit from the window even increased. Expenses only on materials for rent and work. I think this is a way out for me, I open the office again, but now in the city center. I will only sell. Quality It seems to be normal, one is bad that they only sell a profile from cheap pines, all other materials only to order with a period of 10 days. I think that stretching so far in the windows market everything will not become. Just pity to leave, 15 years old devoted the windows.

Alexander Samara