Gas is one of the most sought-after sources for home heating. And if the accommodation is located in close proximity to the main gas pipeline, the device of gas heating at home is the most optimal option.

Content

Features of the use of gas heating

Before the introduction of the heating system, many factors must be taken into account and carry out all the procedures in the correct sequence:

- develop project documentation and get permission;

- purchase appropriate materials and equipment;

- carry out the installation of all elements of the system;

- check its performance;

- perform the launch of heating.

In addition, attention should be paid to the following nuances:

- the power of the equipment installed;

- technical characteristics of heating radiators;

- availability of pools, jacuzzi and other structures;

- the possibilities of combining with additional elements (heated water, "warm floor").

All calculations are carried out at the design stage. To select a more suitable method of heating, also taken into account:

- dimensions of the house;

- structural features of the roof;

- wall thickness;

- the presence of heat-insulating materials.

Based on all these information and choose:

- boiler;

- pipes;

- radiators;

- type of wiring;

- directions of the movement of the coolant;

- the number of household appliances.

Among the benefits of gas heating should be noted:

- the presence of automatic temperature regime adjustment;

- silent work;

- lack of waste;

- cleanliness in the house;

- minimally occupied room space;

- the ability to arbitrary installation of heating communications;

- available cost.

The only thing to take into account when the gas heating device is explosion hazard fuel. Therefore, a number of requirements regarding the placement of equipment should be observed:

- The heat generation source (boiler) is desirable to arrange in a separate room (boiler room).

- The room should be ventilated and have a spare entrance from the street.

- The optimal size of the boiler room is: the minimum height is 2.5 m, the area is 4-8 m².

- The minimum width of the entrance door is 0.8 m.

- The material from which the boiler room is erected should be non-combustible. The brick room is placed and covered with waterfront paint. Wooden room is suitable for asbestos sheets with a thickness of 3 mm or roofing steel.

- The distance from the boiler to the walls should be within 30-50 cm.

- The chimney pipe has a small amount of bends and is located above 0.5 m.

- It is prohibited to install the boiler in the basement.

Choosing a boiler

If a country house is characterized by a sufficiently large area or a complex configuration of rooms and corridors that impede the free movement of heated air, the installation of the heating boiler will be the most appropriate solution.

Gas heating boilers are:

- outdoor and walls;

- c pig-iron and steel heat exchangers;

- single-circuit and dual circuit;

- with electric ignition or piezoelectric;

- with a fan and atmospheric burner;

- with natural and coercive movement of the coolant;

- with a closed and open combustion chamber.

Now there are various heating boilers. It is worth noting that the equipment of foreign producers is designed for nominal pressure in the main gas pipeline, which is in the range of 18-20 mbar.

Reduced pressure may result in negative consequences, as a result of which in cold winter days it can be left without heat. It happens that in normal conditions the boiler will be able to heat the room with an area of \u200b\u200bup to 300 m², and when the pressure drops, effective heating will be achieved on an area of \u200b\u200bonly 150 m².

Wall and outdoor equipment

To install a modern wall boiler, you will not need a separate room. Due to the horizontal coaxial pipe, the elements of the boiler can be output through any of the walls of the house. The boiler itself can be placed in a convenient place where it will not interfere with anyone. The only nuance is that it is recommended to acquire wall-mounted equipment with a capacity of up to 24 kW.

Installation of an outdoor boiler is desirable to carry out in the utility room. Be sure to build a concrete stand (asbestos blocks can also be used). The places of contact of the elements of gas equipment with the surface are sealed with a clay solution, which will not allow the appearance of cracks.

Heat exchanger

The material for the manufacture of the heat exchanger can be:

- cast iron;

- steel.

Cast iron products are pretty heavy. They need to be very gently transported and installed. But cast iron heat exchangers have an undoubted plus - they are almost not corrosion.

For this reason, the operating period of the cast iron heat exchanger is about 50 years. Which exceeds the service life of the steel product by more than 3 times (15 years). This difference is due to the fact that steel heat exchangers do not differ in corrosion resistance.

The occurrence of corrosion in gas equipment is associated with:

- the presence of air in the coolant;

- the appearance of condensate, which, when cooled, settles on steel walls.

Contour of the boiler

When choosing equipment for this criterion, the following is taken into account. If there is no need for hot water consumption, then a gas boiler is bought for home heating with one contour.

But in modern conditions it is difficult to imagine comfortable accommodation in the house without hot water supply. Naturally, the best option (albeit more expensive) will be the acquisition of a gas boiler that has two contours.

Burner, method ignition and power

The gas pressure in the main pipelines is subject to sharp drops, and even to 13 mbar can decline in winter. It is fraught with a decrease in the flame in the burner, which becomes the cause of its rapid burning. For this reason, the most optimal option will be the use of a boiler equipped with a fan burner.

As for the ignition method, the main criterion of choice is the need for gas saving. The electrical ignition method will significantly reduce gas consumption. Turning on and off the boiler happens in automatic mode. But there is one nuance - when the electricity is turned off, there is a high probability of staying without hot water supply and heating.

If the ignition is carried out with a piezoelectric unit, the gas flow rate will be slightly larger. This is explained by the fact that in the boiler there is a constant burning of a small stamp, waiting for the heating of hot water or heating system.

As for the power of the boiler, its optimal value is determined based on the area of \u200b\u200bheated premises. On average, for heating 10 m² housing, 1 kW of energy will be required. If there are ceilings, the height of which is over 3 m, the boiler power should be twice as much. It is also necessary to consider that ¼ part of the power goes to heating water.

Automatic system

The greatest problem of gas heating is the high probability of fuel leakage. The reasons for this phenomenon can be different:

- sharp decline in pressure in the highway;

- involuntary attenuation of the burner or stobble;

- bad thrust in the chimney channel;

- disable electrical power supply.

All data factors (with the exception of the latter) are difficult to identify manually. Various automatic devices are designed to identify gas heating problems:

- sensors controlling the force of thrust and the level of the burner flame;

- the device that stops the operation of the boiler when the electrical energy is turned off;

- heat carrier control sensor in the heating system;

- a device blocking the boiler with a sharp pressure drop in the gas pipeline;

- scale removal systems and diagnostics;

- safety valve for the heating circuit;

- instruments that protect the boiler from freezing.

Due to the explosion hazard of gas equipment, only such a boiler must be purchased, which is equipped with automation diagnosing any non-standard situation. Among the innovative developments, which will make the work of the boiler more secure, should be mentioned about the programmer. Thanks to this novelty, the owner of the house will see all the faults of the heating boiler on a digital display.

Mounting work

To install elements of gas heating at home, you need to get permits. Only after visiting the relevant services (BTI, fire and gas supervision) proceed to assembly work.

Fastening the boiler is carried out on the planks. The mounting height is 0.9-1.5 m from the floor. The wall where equipment will be, should be smooth and durable. If it is made of a fuel material, it is protected from the boiler using a heat-resistant gasket with a thickness of up to 3 mm. The fixation of the boiler is as follows that there is a distance of 4-5 cm between it and the wall.

At the next stage, a boiler connects with a gas pipeline:

- the cap of the boiler is connected to the element of the gas pipe, where the valve with the valve is located;

- a filter is mounted on the crane, which will adjust the flow of fuel and protect the system from garbage from entering;

- joints of the elements of the boiler with a gas pipeline seal the paint or packles;

- filters with a flexible connection are mounted (it is impossible to use rubber hoses, which over time dry and crack);

- with the help of precipitated nuts and paronite gaskets, the connection of nozzles and hose.

It should be noted that only metal pipe applies to connect the boiler with a gas pipeline. To achieve a maximum hard connection, it is recommended to use an "American" or special Sgon.

Next, the boiler is connected to the water supply system. This procedure has its own nuances:

- The main distinguishing feature is the use of pipes of various diameters and different cranes (compared with the connection of the boiler to the heating system).

- Wiring of cold water involves the presence of mesh filters that prevent the clogging of the gas boiler.

- To disable water supply, mounted cranes that have detachable connections. It is necessary for easy replacement of the crane in case of its failure.

- Before connecting the boiler to the pipe of the water supply pipe from the nozzles, protective caps are removed. No pipes are located in such a way: on the left - for cold water, on the right - for hot water supply.

In the process of installing equipment for home heating, the following rules should be followed:

- compliance with a small slope of pipes;

- preventing the narrowing of the entry / exit elements on the boiler;

- device drainage of the coolant between the boiler and the flow of the gas pipeline;

- all types of expansion tanks and radiators must comply with the norms of using the coolant;

- installation of the expansion tank is carried out at the highest point;

- separation of all elements of the heating system with cranes;

- the boiler must provide efficient heating of the entire area.

After carrying out installation work, the heating system is filled with the coolant. The boiler should not be air, which can cause ignition or disruption of the working cycle. To prevent the formation of airbags for airbags, the filling of the system is reached upward.

At the final stage, the quality of equipment installation is inspected. As a result, the correct installation work should not be:

- gas release;

- water flow;

- cable breaks in vertical and horizontal planes.

It is clear that the presence of leaks is determined by the visual way. To detect, gas leakage should be used by a soap solution that are wetted pipes. If there are no air bubbles after some time, then the communications are connected qualitatively. Only after careful testing of the quality of the work performed the final launch of the heating system.

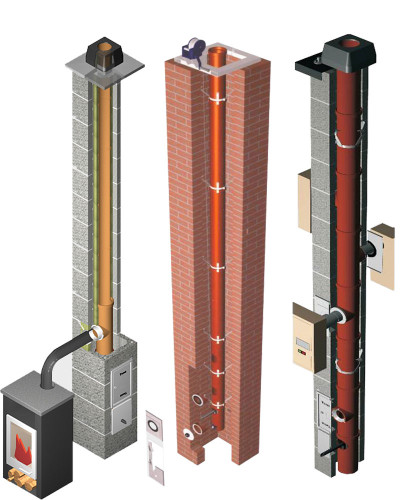

Nuances of the smoke device

Installation of the boiler is accompanied by a mandatory device of an effective chimney. This process is carried out after purchasing a gas boiler, since the size of the chimney is directly dependent on equipment dimensions.

The size of the useful section of the pipe (the length of the chimney multiplied by the inner perimeter of the pipe) must exceed the internal area of \u200b\u200bthe boiler. If the chimney dimensions are smaller than the boiler area, then it is necessary to increase the length of the pipe.

During the chimney device, the following requirements should be taken into account:

- There should be no branches of more than 1 m in size, and the number of curves or knees should not exceed three units.

- Some elements of the chimney are installed at an angle of no more than 30º.

- In transverse sections there should be no tapering sites and ledges.

- The places of turns of the chimney are equipped with a hatch, with which condensate is removed.

- Lack of gaps between individual parts of the chimney.

- The inner side of the pipe should be without roughness.

- When installing horizontal parts of the chimney, their length is from 3 to 6 m.

- Dense pipe connection.

- Lack of bending elements and connections in places of contact with the roof.

- Warming of pipes when placed in unheated places.

Coaxial pipes

There is an option when to connect the gas boiler you do not need to equip the chimney to remove the combustion products. To do this, use a horizontal tube, which is extended to the street through any of the walls. It is called a coaxial pipe.

When using this system, not only removal of waste gas, but also the flow of fresh air is happening. In fact, the coaxial tube consists of two pipes that are inserted into each other:

- the first pipe displays combustion products;

- the second tube supplies the system with fresh air.

If the choice fell on a coaxial pipe, one of two types of double-circuit boilers should be purchased:

- parapet (for the heating of buildings up to 150 m²);

- with forced air vent (for heat supply of premises Over 150 m²).

A few words about autonomous gas heating

If the country house is located away from the highway, then for the device of autonomous gas heating, you can use cylinders or gazgolders. For heating a small house, it will take 3-4 cylinders (40 l) per month.

Gas convectors can be used as heating equipment. They are attached to the walls in the rooms where heating space is planned. Depending on the size of the rooms, convectors with a certain power are purchased.

The main advantages of gas convectors are:

- undoubtedly electric power supply;

- heating the room as a short period;

- solid gas savings.

Video about nuances of gas heating device: