Warm garage in winter - a necessary condition for carrying out car repair work. In addition, in the cold room, the engine of the car is poorly started, the battery capacity is reduced. Effectively solve such a problem by installing homemade ovens for the garage. What kind of heating equipment and the technology of independent manufacture will be presented below.

Content

The selection of the furnace design depends on the availability of fuel. The greasy furnace for the garage is most popular. It can be made in the form of a metal burzhuyki or composed of bricks.

In second place - burzhuyka, as a fuel for which the waste motor oil is used. The gas furnace for the garage is dangerous in operation, its use is not recommended.

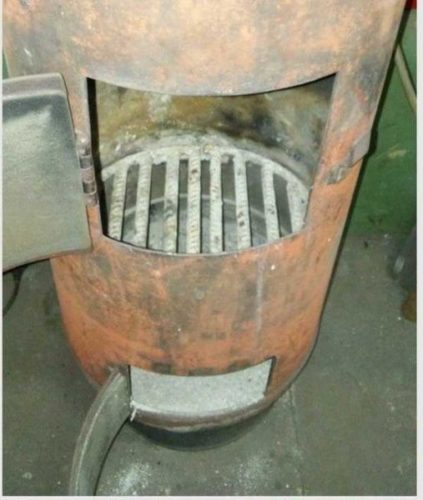

Cylinder garage furnaces

The oven for the garage from the cylinder can be made in the form of ordinary bourgeities. But the cylinder is important to choose correctly. You must pay attention to the following:

- it must be seamless and made exclusively from steel;

- the cylinder capacity should be no less than 12 liters, the best option is 50-liter, 0.85 m height;

- on metal should not be traces of deep corrosion;

- the valve cylinder is preferable than with the valve: the valve can be used as an oxygen supply regulator in the combustion chamber.

We make the oven for the garage with your own hands. Making Bourgearies: Phased Description

The main components of the stove from the cylinder are the flue compartment with grate, puffed and the chimney pipe. In the upper part can be arranged a cooking surface.

The following tools and materials will be needed for work:

- gas cylinder;

- steel corners for the manufacture of the stand;

- armature with a diameter of 10-12 mm (for grate);

- sheet steel with a thickness of 3 mm;

- metal tube with a diameter of 80 mm with a length of 1.5-2.0 m;

- loop for doors;

- bulgarian;

- welding machine;

- electric drill with drill set;

- hammer;

- screwdriwer set;

- file;

- adjustable wrench;

- gas key;

- metal brush.

The metal furnace for the garage is manufactured in the following procedure.

- Using a gas key unscrewing the valve with a rim. Pre-threaded connection must be treated with WD-40. When unscrewed, light tapping hammer is allowed.

- Gas condensate merges in compliance with fire standards.

- Cold water is poured through the hole in the balloon: it will displace the gas remaining in the container.

- With the help of the grinder make cutouts for the door of the fiber and pushed. Acute faces and burrs processing a file.

- With the help of bolted connections, install the doors of the furnace and pondered on the loops. Handles and constipation should also be attached (cut from sheet steel).

- Cut the reinforcement on the segments for the manufacture of grate. We weld the lattice from them so that they can be put in place through the door of the fuel. As a shelf for grate with the inside of the balloon at the desired level with the help of welding, secrets.

- From the corners, cut the parts for the stand (or for the legs) and weld them to the cylinder.

- From the opposite side (at the top), cut the hole for the chimney pipe.

- Pipe prepare: bend or weld two fragments (short and long) at an angle. The field of this weld it to the place with a hole prepared for the chimney. For reliability, secure the pipe to the top of the bourgearies with a jumper from the corner.

- We weld the plate of sheet steel in the form of a circle with a diameter of 200-250 mm to the top of the burzhuyki. It will serve as a cooking surface on which the dishes can be put.

- We clean the place of welding, paint the stove with heat-resistant paint.

IMPORTANT: Bourgeisk must be sustainable - this is the main security condition. The construction of the stand (legs) should be wide.

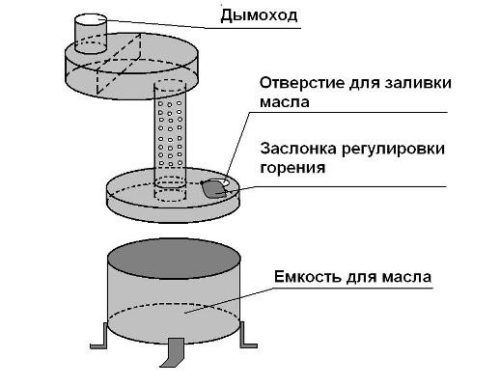

Garage oven on spent machine oil

A solid fuel furnace for the garage is not the only option. As a fuel, it is possible to use workflow - old machine oil, which is always in motorists. Such a furnace can also be made of a gas cylinder. Its creation technology can be divided into several stages.

- Wave gas by opening the valve or pressing the valve.

- Recove the valve and merge the gas condensate from the cylinder. Fill the tank with water (it will displace the remaining gas).

- The marker outlines the locations of the cuts according to the drawing.

- On the side of the bottom, retreating from the bottom of 200 mm, cut off part of the cylinder.

- We weld the legs to the cut part. It will serve as a primary combustion chamber.

- From sheet steel, 4 mm thick cut the circular lid for the primary chamber. The lid should be removable (for filling the oil).

- A hole with a diameter of 100 mm in the center of the primary chamber cover is cut. We weld the pipe of the same diameter with a length of 0.5 m in place of the opening. Pipe wall thickness - minimum 4 mm. Perforation holes are drilled in the pipe. They will ensure air access to ignite the unburned factions.

- With the edge of the lid, the hole is cut with a diameter of 50 mm and fasten the damper. This hole will serve as a fuel pouring. The flap is needed to adjust the amount of air entering the combustion chamber.

- From the upper part of the cylinder, the camera is made, externally similar to the firebox. This camera is designed to cool gaseous combustion products. On the way to the chimney, a partition is arranged, blocking the right way to gases to the pipe.

- With the edge of the upper chamber welded a chimney with a height of at least 4 m.

Note: Overbill furnace can be made entirely of sheet metal with a thickness of 4-5 mm. In this case, the combustion chambers and gas cooling will have parallelepiped form.

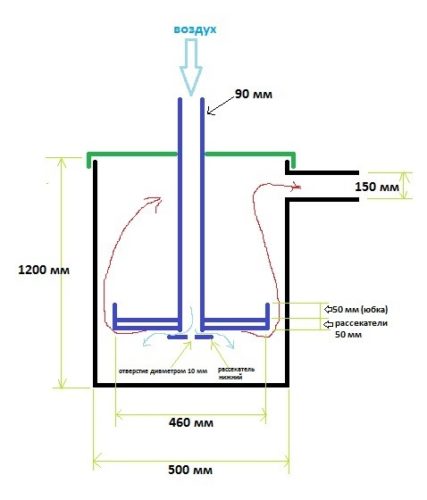

Solid fuel oven for garage of long burning

There are other options for a garage oven using firewood. The stove of long burning, which is called bunch, has advantages:

- you can use any solid fuel (wood, chip, coal, corn and sunflower recycling waste);

- the combustion process does not require frequent observation (it is enough to add fuel once a day).

The technology of manufacturing bubfoni from a cylinder with a capacity of 50 L assumes the following sequence of actions.

- Plums from the cylinder gas and condensate merges.

- The upper part of the cylinder is cut with a grinder. It will serve as a lid, for which the stops are welded at its edges.

- From sheet steel (with a thickness of at least 5 mm), a circle is cut, a diameter of less than several millimeters than the cylindrical inner part of the cylinder. The circle will serve as a piston freely moving inside the cylinder. For rigidity from the center of pancakes to edges radially (from the bottom), several segments of the corners or profile pipes are welded. These ribs will also prevent the tight fit of the piston to fuel, which can prevent air access.

- In the center of the panca cut the hole with a diameter of 90 mm and weld the trumpet of the jack, its perpendicular to the plane. Over the pipe in the combustion chamber will pass oxygen. The length of the pipe per 100 mm should exceed the height of the furnace.

- In the lid cut the hole for the piston pipe. The diameter of the hole should allow the air freely penetrate inside.

- Rates approximately 100 mm from the cover down, cut the hole for the chimney. Exhaust exhaust gases will be better if the chimney diameter is not less than 100 mm.

- We make chimney with a horizontal section of 400-500 mm and a knee for connecting to a vertical pipe (a height of at least 2.5 m). It is desirable that the chimney is collapsible (for cleaning).

Tip: In the event that the valve cannot be immediately unscrewed, you can carefully drill a hole at the bottom of the cylinder through which you need to drain the condensate and pour water into the container. After that, work with a grinder will be safe.

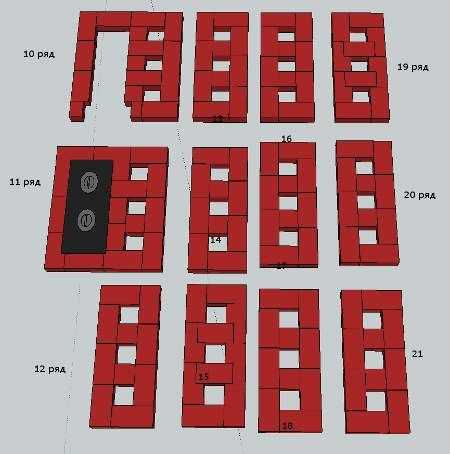

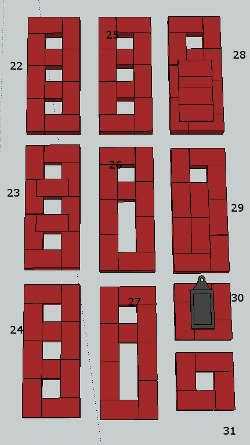

Drawings of the garage furnace can be found on the Internet, we bring to your attention one of the design options.

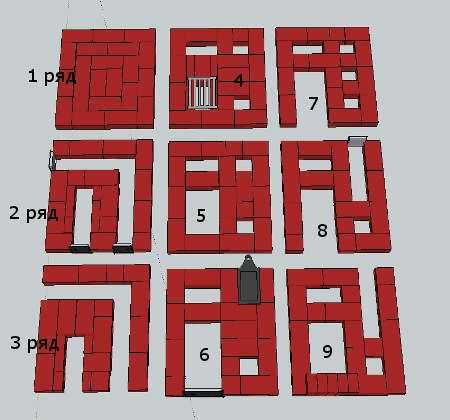

Brick garage furnace with her own hands

The brick oven for the garage will not require large base costs: the foundation for it will serve a slab floor. This option of heating is suitable for motorists often operating in the garage.

The following materials are needed to build the furnace:

- red ceramic brick - about 300 pcs;

- opening door - 1 pc;

- the door for pissed - 1 pc;

- the catch - 1 pc;

- grill grate - 1 pc;

- cooking plate - 1 pc.

The rules of furnace structures are as follows.

- Observe the order specified in the Scheme.

- Use a special solution for masonry furnaces or clay with sand and cement. Chamotte solution is required for the furnace.

- Brick should be chosen without cracks, well burned.

- Between the brick and the doors of the furnace with a confusion should be a gap to compensate for the temperature expansion of the metal. Asbestos cord can serve as a sealer.

- The catch is necessary to select the operation mode of the furnace (winter or summer). It is installed in the sixth row.

- If necessary, the height of the stove increases due to the repetition of the rows.

In conclusion, we offer a visual material - a garage oven (video with specialist comments). Such a stove will fit even in a small garage.