Concrete stairs are reliable, durable, durable, but unfortunately completely unattractive. Naked gray concrete is unlikely to look good in the apartment, if, of course, it is not performed in the style of Loft. In most cases, concrete ladders are trimmed by a tree to give them a beautiful and "home" view. Make it is quite simple, if you understand the specifics of the device and operation of the structure. In this article we will discuss how to seize the concrete staircase with your own hands.

General characteristics of structures

Concrete ladders can rightly be considered the most reliable and durable. They have advantages even over iron structures, since they are subject to corrosion. Concrete will not be able to destroy no moisture or household mechanical effects, so it is used not only outside, but also indoors.

Of course, the concrete staircase installed inside the house should not be bare and gray, as the stages in the entrances, so it is trimmed with finishing materials - tiles, laminate, porcelain stoneware, tracks or wood. The tree is most popular because it makes it possible to drastically change the appearance of the stairs, make it more comfortable and beautiful.

The advantage of the wooden staircase of the stairs is also in the fact that, unlike tile or laminate, it can keep warm in winter and give coolness in summer. This is an excellent material that can adapt to changing conditions. With proper installation and processing, the wooden coating will serve not one decade.

What is the stairs

To understand how to finish, it should be understood from which the staircase is. Concrete construction is inherently elementary, but in the process of decoration by wood, it may become more complicated and gain new elements.

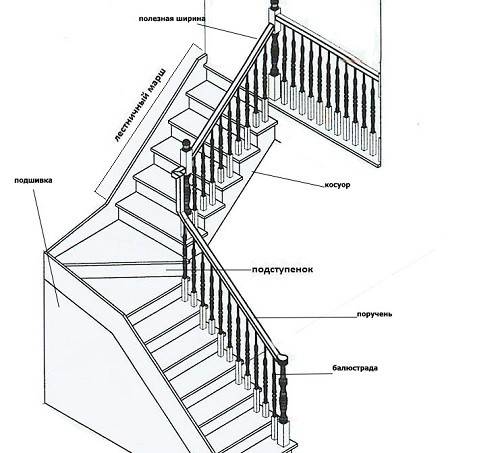

In order to facilitate the perception of the information below and do not stop on the clarifications, we give a description of the most common elements of the staircase:

- Ladder march - a fragment of the stairs (or the entire staircase, if it consists of one part), which begins and ends with a staircase. The design may consist of one or more staircase marches (usually no more than 2).

- Useful march width is a distance between opposite handrails of the stairs, between the handrail and the wall or between the handrail and the central stand, if the staircase is a screw. Measure the useful width of the march should be at the level of handrails, not steps.

- Kososor is one or more beams that go under the staircase and are carrier elements. A steps are based on the cosospore, so it should be very powerful to withstand the weight of the design and load during operation. Kososoras are made from reinforced concrete, wood or metal, while the beams can be both straight and different shapes - in the form of arches, gear or carved.

There are stairs on two cososoors on both sides of the steps and on one central Kosor. - Closed staircase - most concrete stairs applies to closed type, that is, they have risers. Due to the presence of risers, the stiffness of the structure increases significantly, which is extremely necessary for marches with a large useful width of 110 to 150 cm.

- Open staircase - design without risers with marches, open on clearance. Such concrete stairs are used indoors and do not possess that rigidity that closed. They are not so massive and the interior does not take care of their presence, so they can be used even in small rooms.

- Line is a conditional direction that runs on the working ribs of the stairs of 30-50 cm from the axis of the inner handrail. The line of the stroke should not necessarily coincide with the central line of the march. So, if the useful width of the march is 60-100 cm, the line will pass in the center, in the case of wider marches from 1 m to 1.5 m, the line of the stroke will shift towards the main handrail. This is explained by the fact that the person, going down or rising along the steps, is kept behind the main handrail, and the line of move is determined by the position of the person at the time of being on the stairs.

What does the line of stroke affect? For direct simple stairs, it is not so important, but for designs with run-down steps, this parameter should be taken into account, since the width of the sticking on all steps must be identical. Exceptions are only the front stages that are allowed to do lower and wide. - An angle of lifting - this parameter depends on the width and height of the sticky and affects the convenience of using the stairs. So, the design with a steep rise to climb will be pretty hard, even if it is straight and single-hour. If you make an angle too big, then such a common staircase will also cause discomfort. The most convenient angle of lifting is in the range of 30-40 degrees.

- The risers are a vertical element located under steps and closing spans between them (in the closed stairs). Provides an additional support and increases the stiffness of the structure. In this case, the risers can be made of a less durable wood. For example, if the facing of the concrete staircase is carried out with an oak or larch, then the risers can be made of pine.

- Handrail - element for support while lifting or descent on the stairs. The height of the handrail is usually standard and ranges from 90 to 96 cm depending on the width of the march and the growth of residents of the house.

- Balustrade - the fencing of the staircase between the steps fixed by the handrail. It consists of a number of columns (direct or carved) located at a certain distance from each other. The distance between the columns should be not more than 20 cm, and if small children live in the house - no more than 15 cm. At the same time, construction norms oblige not to do a solid balustrade or with a distance between the columns less than 7.5 cm, since in case of fire between them Complete fire sleeve.

- Pad - Facing the invalid part of the staircase march. It can be made of drywall, decorative panels, panels with thread or panels.

Choosing wood

The sheathing of the concrete staircase with a tree in a residential premises is necessary for a number of reasons, but they all reduce the two principles - practicality and aesthetic. Almost all breeds of wood correspond to the desired characteristics, but for a solid concrete structure, which will serve not one dozen years, it is better to select the material of the corresponding durability. Optimal breeds for concrete cladding is the oak, larch, beech and ash. If you are not constrained in the means and want to give the interior of originality and luxury, you can use exotic breeds - Merbau, Wenge, rosewood, Eben Makassar, etc.

Useful advice: If you are finishing a closed concrete staircase, up to save the funds of the risers can be made of cheap wood, for example, pines. With the help of a verse, give it a shade, as close as possible to the color of the steps.

When choosing wood for finishing a concrete staircase, the energy characteristics of rocks should also be taken into account. So, the Oak will create a good "male" chalet interior, the ash with his noble gray shade is suitable for lighter interior, the beech will be well combined with a monophonic laminate of rooms and create a light relaxed atmosphere.

Consider the characteristics of the most popular rocks for staircase:

- Oak is a favorite among finishing materials for stairs. This is explained by his enviable durability and a beautiful texture. It is resistant to minor mechanical damage, so if you inappropriately drop the heavy item, dents or chips will not remain. The peculiarity of the wood is that over time she darkens and acquires noble shades. If you wish, you can form a surface with a simulator.

- Larch is a relatively inexpensive material that is not inferior to oak strength. It has a beautiful gentle texture of various bright shades. Often, larch is stained with a verse for imitation of exotic and expensive wood breeds.

- Ash - despite the fact that the ash is less than the oak, it is much stronger and more durable. It is characterized by a characteristic gray texture and a variety of shades, so it's not difficult to choose an ashole board for any interior.

- Beech is characterized by a homogeneous texture with small fibrous splashes. It looks good in modern loft style interiors, combined with light shades of laminate. Pretty robust wood at an affordable price.

IMPORTANT: For the facing of the steps, you should not choose such soft wood species like a pine or a lip. Although they are easy to handle them, but they will not last at all. Over time, the steps will begin to creak, to join and quickly lose an attractive appearance. Many make a mistake, seduced by a beautiful texture and cheap pine, but it is better not to save on the facing of the steps of the concrete ladder, especially since durable rocks can be found cheap options.

Depending on the designer idea, the finish of the concrete staircase can be performed completely, closing the steps, the risers and making the trim, or partly. With partial finish, leave the sidewalls or the back side of the structure. This solution is suitable for modern interiors in Loft style, High-tech, grunge. Full cladding creates the impression that the house has a good expensive ladder from massive wood.

When choosing a facing material, consider that it should be combined with a tone with a common interior of premises - wall decoration, floor, color of furniture. Harmony should be observed not only in color, but also in a style decision. So, the carved elements of balustrades and handrails will be inappropriate to look in minimalistic design, and vice versa.

Ladder sheathing

The material that the concrete staircase will be finished must be as durable as the floor covering the rest of the room. Ideally, it is recommended to use one breed of wood. The cladding boards should be at least 30 mm, otherwise their rigidity will not meet the operational requirements.

If you make a major overhaul, attach the second floor or build a house from scratch, it is recommended to start the ladder to design only after the completion of all finishing works on the second (third) floor. Otherwise, walking along fresh wood in shoes and construction litter can spoil the appearance of the stairs much earlier than the deadline.

During laying a facing material, constantly check the height of the steps with the help level. The difference even a few millimeters will lead to the fact that residents of the house will constantly stumble on such a high or low step. It is allowed to maximize the rejection of the height of up to 5 mm. To align the height, use concrete solutions with reinforcing grids.

Progress:

- Measure all the stairs and find the highest of them (rarely when concrete stairs come across the altitude staircases identical). Hang all other steps in height with the highest with a classic cement-sand solution. Strengthen the design of the reinforcing grid. This should be done only if the differences are more than 1 cm, in other cases, it is possible to align the steps with direct laying of the facing.

- After drying the leveling screed, you get dust from it and cover deep penetration with the primer composition. It will strengthen the density of concrete and create optimal conditions for applying adhesive composition. If you apply glue directly on bare concrete, then the porous structure will take moisture from the solution, and it will lose its adhesive qualities.

- Staying the cladding directly to the concrete can not - necessarily need a buffer layer (substrate). For this, in most cases, a conventional phaneer is used with a thickness of 10-15 mm, gluiting it with moisture-resistant mastic. For additional fixation, it is recommended to fasten the Faneur dowels. As a substrate, you can also use cork flooring, which will absorb vibration when walking on the stairs. The image below shows how not to lay boards on the concrete staircase:

If you stick to the trim directly to the concrete, then such steps will last long, because without a shock absorption substrate they quickly fall out, it will begin to creak and ultimately fall off. - When the mastic grabbies, Phaneur should be treated with primer and glue the wooden steps. For risers, the substrate is not needed. Steps should be made in advance or order in a plumbing workshop.

- Stacking steps on liquid nails must begin from below, moving above on the stairs.

- Hats of all fasteners need to be dragged into the wood into a few millimeters, after which we mask with a putty on the tree of the appropriate shade.

- After gluing each stage, check the solidity by the construction level.

- The risers are joined with steps through pre-cut grooves. The grooves should also be labeled with glue.

- When all the steps are installed, wipe them slightly wet rags to remove dust, cover the wood veil, if you want to imitate the elite breed, or transparent high-strength varnish. It is better to give preference to the weather-resistant varnish, for example, a yacht or special furniture nitroquac. The last more sharp smell, but it dries several times faster than the yacht.

The facing of the concrete staircase with the tree with their own hands when possessing minimal skills of treatment with wood and woodworking tools - hacksaw, branches, etc. To shorten the deadline for the installation and facilitate the work, you can order steps and risers in the joinery workshop - you will only stay to the substrate and collect the trim in the design of the designer.